What is the DensiDry inline volume and moisture meter?

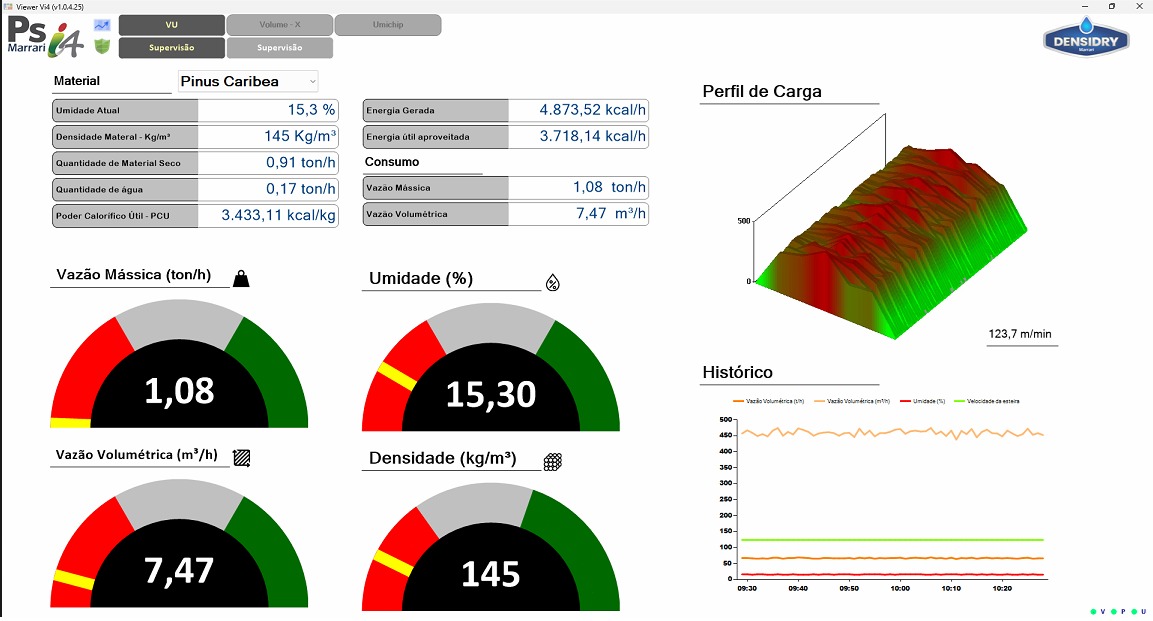

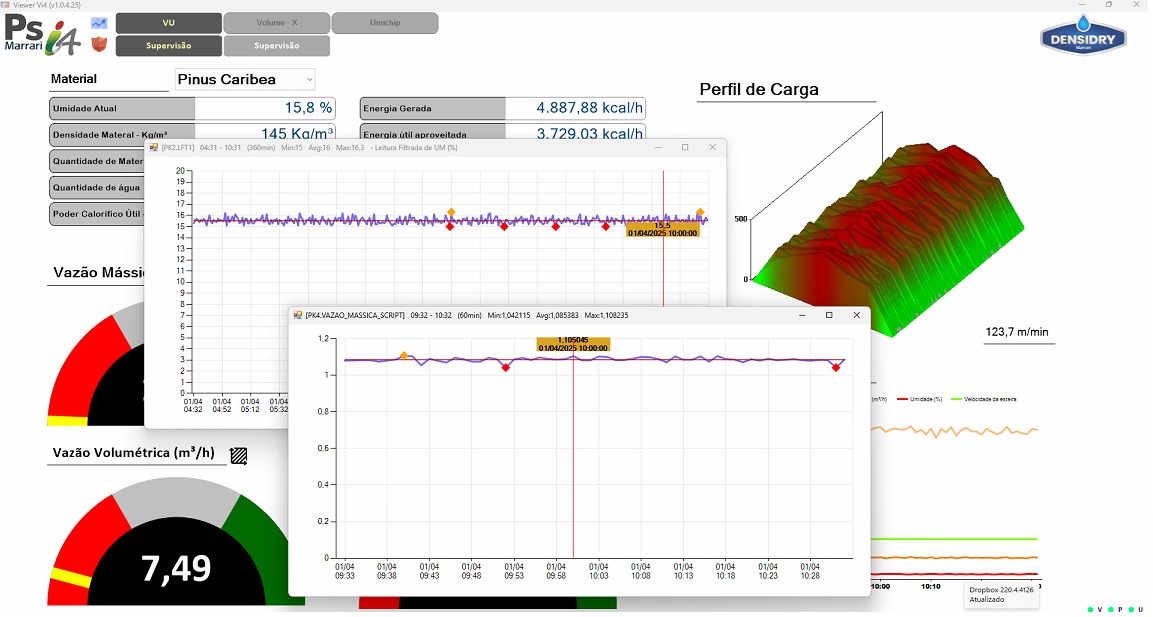

The real-time system for measuring moisture, volume, and weight for biomass and boilers, known as DensiDry, is the result of integrating the technologies from the Volume X and UmiChip product lines and their respective variations. Together, these devices provide a broad range of essential information designed to significantly enhance the energy generation process in industrial boilers.

This innovation plays a crucial role in improving the energy efficiency of industrial boilers, promoting resource savings and reducing biomass consumption during the combustion process. The DensiDry biomass measurement system provides real-time insights into the volume, weight and moisture of the biomass used, allowing for precise, informed adjustments that help optimize the performance and sustainability of your energy generation system.

Why use the DensiDry biomass measurement system?

Quantifying and qualifying raw materials or the final product in a production line is essential for effective operation.

Example: knowing the moisture content of the biomass feeding a boiler allows for its proper adjustment, ensuring its efficiency. Knowing the volume of fuel used informs us about its performance. Thus, this real-time data ensures the effective operation of the system. The same logic applies to numerous industrial processes.

In the example above, when the wood chips are too wet and placed in the boiler for combustion, the boiler must first evaporate the water (losing pressure in the process) before burning the wood chips and generating energy.

While volume is important to avoid suffocating the boiler, if too much material is fed, there is a risk of generating too much pressure and causing the boiler to burst.

Learn more about the biomass process and how it affects the entire energy generation process in our articles by clicking here.

How does DensiDry manage to be SO PRECISE?

The volume sensor works via laser and is not affected by temperature, light, or humidity when installed correctly. Additionally, the accuracy is high, with a margin of error of only 3%.

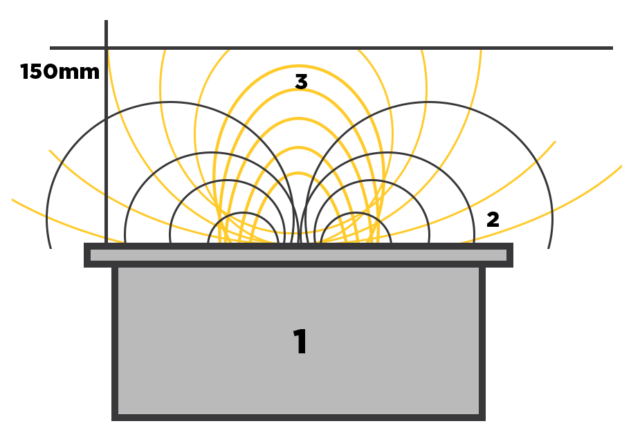

The moisture part works through the capacitive method, meaning a sensor is installed on the conveyor belt, and as the material is carried along it, it passes over the sensor (1) and the moisture content of the product is measured second by second in a height range of up to 150mm (2 and 3). This allows for an actual measurement of the moisture content of the entire material, not just the surface.

What are the benefits of using a biomass measurement system for inline volume, moisture, and weight?

- Quality control: The moisture meter helps ensure that the material meets the required quality standards for boiler operation, helping to prevent issues such as incomplete combustion and unwanted residue formation.

- Energy savings: The volume meter helps optimize fuel consumption, avoiding over or under-feeding the boiler. This can lead to reduced energy consumption and cost savings.

- Increased energy efficiency: With precise control over the material’s moisture and volume, the boiler can operate more efficiently, maximizing energy production from the fuel.

- Reduced maintenance costs: The use of the moisture and volume meters can also help reduce boiler maintenance costs by preventing issues like deposits and corrosion caused by excess moisture.

- Reduced environmental impact: Precise control over the material’s moisture and volume allows the boiler to operate more cleanly, producing fewer emissions and waste. This helps reduce the environmental impact of boiler operations.

Benefits for the safety of your operation:

The DensiDry system, with its sensors, can detect misalignments in rollers and conveyor belts, helping to prevent accidents and damage to workers and equipment. Misalignments can result in conveyor malfunctions, misalignments, material spills, and collisions, which can cause significant injuries and material damage. Causes may include maintenance issues, natural wear and tear, and weight overload. Companies should perform preventive maintenance regularly and monitor conveyor performance to ensure worker safety.

The DensiDry biomass measurement system goes further by monitoring the conveyor belt rollers. The system can provide various benefits to the process, such as reduced repair, maintenance, and injury compensation costs, improved quality of transported products, increased equipment durability, a safer work environment, and enhanced productivity. By identifying and correcting roller misalignments, it is possible to ensure the proper functioning of the conveyor belt and prevent accidents, resulting in a more efficient and safer process.

WHAT OTHER FEATURES DOES IT OFFER FOR MANAGEMENT?

The volume system also includes various performance features such as OEE (Overall Equipment Effectiveness), allowing you to monitor minute-by-minute data on machine uptime, downtime, operator efficiency, material quality, and more. It even sends emails and alerts if any production issues arise. By combining these three factors, you will have the efficiency index of that production or line.

The moisture part can track real-time moisture content and can self-adjust based on lab tests.

Learn more about OEE and its importance in today’s global production scenario by clicking here.

WARRANTY

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!