WHAT IS THE IN-LINE MOISTURE METER FOR PAPER UmiPaper?

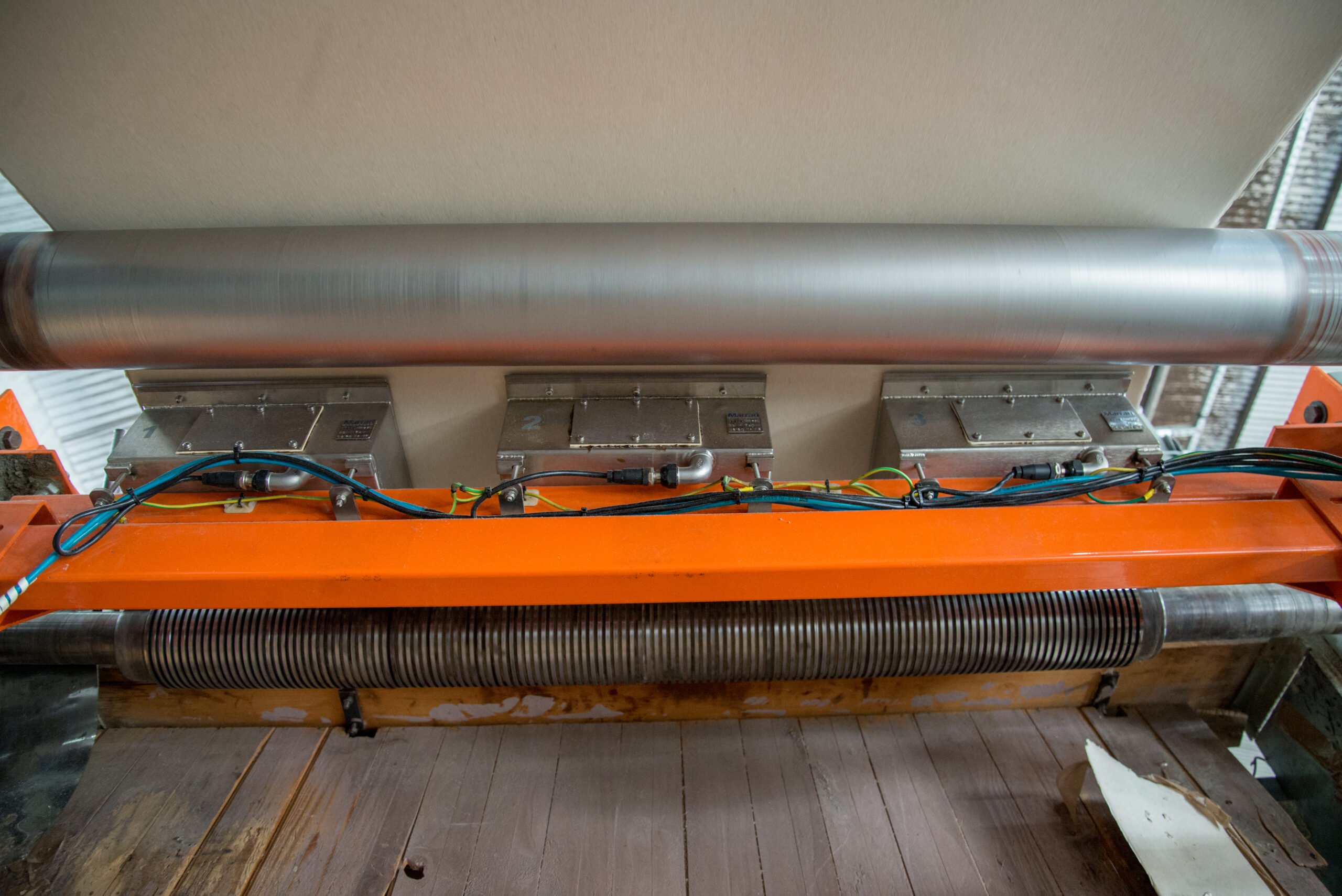

The in-line moisture meter for paper, UmiPaper, is Marrari’s solution for real-time moisture measurement for paper passing on a conveyor belt or production line. It features a sensor with a capacitive active principle, meaning the measurement is more precise and faster than resistance-based methods.

WHY USE UmiPaper IN MY PRODUCTION LINE?

Because measuring the moisture of your material/product is essential to maintain its quality. For example: when placing paper on rolls and if any part is damp, this moisture can spread to the rest of the roll, compromising production and the final product.

Additionally, accurate humidity control in paper production can lead to savings in chemical materials, thus reducing production costs.

Benefits of real-time moisture measurement for paper, cardboard, and other cellulose-based products:

Product Quality

Precision in Composition:

Enables precise humidity control, ensuring the desired consistency and quality of paper and related products.

Operational Efficiency

Process Optimization:

Facilitates real-time adjustments during production to enhance operational efficiency and minimize waste.

Loss Reduction

Avoiding Product Degradation:

Helps prevent raw material losses due to humidity variations that could compromise product integrity.

Cost Control

Efficient Resource Use:

Contributes to cost reduction by preventing the excessive use of raw materials and energy.

Compliance with Standards

Meeting Regulations:

Supports compliance with regulations and quality standards related to moisture content in paper and cellulose products.

Health and Safety

Preventing Health Issues:

Helps avoid health risks related to the presence of mold or unwanted microorganisms in humid paper products.

Proper Storage

Stability and Durability:

Positively impacts the stability and durability of the final product, preventing storage issues and extending shelf life.

Climate Variations

Adapting to Climate Conditions:

Allows for dynamic adjustments in response to climate changes that may affect the production environment’s humidity.

Traceability and Quality Control

Facilitating Traceability:

Real-time measurements enable rigorous quality control, allowing for quick identification and correction of process variations.

Technological Innovation

Adoption of Modern Technologies:

Demonstrates a commitment to innovation by incorporating advanced technologies to ensure quality and efficiency.

Customer Satisfaction

Delivery of Reliable Products:

Ensures customer satisfaction by consistently delivering reliable and high-quality paper products.

Eco-efficiency

Sustainable Production:

By reducing resource waste, humidity measurement promotes more sustainable production practices.

By incorporating real-time humidity measurement, manufacturers of these products can significantly enhance the consistency, quality, and efficiency of their production, resulting in both operational and environmental benefits.

HOW DOES UmiPaper WORK?

It operates via capacitance, meaning a sensor is installed on the conveyor, and as the material is carried by it, it passes over the sensor, and the product’s moisture is read second by second. Thus, providing a real-time moisture measurement.

HOW IS UmiPaper SO ACCURATE?

It uses a calibration method based on recipes. In short: you use the Tracker (equipment that comes with UmiPaper) to collect samples throughout the day and compare them with the laboratory.

If there are discrepancies, you can go to the Tracker’s included software and update the values to match the laboratory assay, thus ensuring its accuracy.

IF I WANT TO BUY THE METER WITH A READY RECIPE FOR MY PRODUCT?

Just send a sample of your product to us at Marrari. Specifically, to Umilab, where we will create a specific recipe for you based on the laboratory assay!

Contact us to learn more!

AND WHY USE MARRARI EQUIPMENT?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss, using methods such as OEE and Industry 4.0. Thus, creating a more effective, productive, and modern production environment!

If you want to learn more about us and automation news, visit our blog, Facebook, or LinkedIn.

WARRANTY

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!