What is the Volume X in-line volume meter?

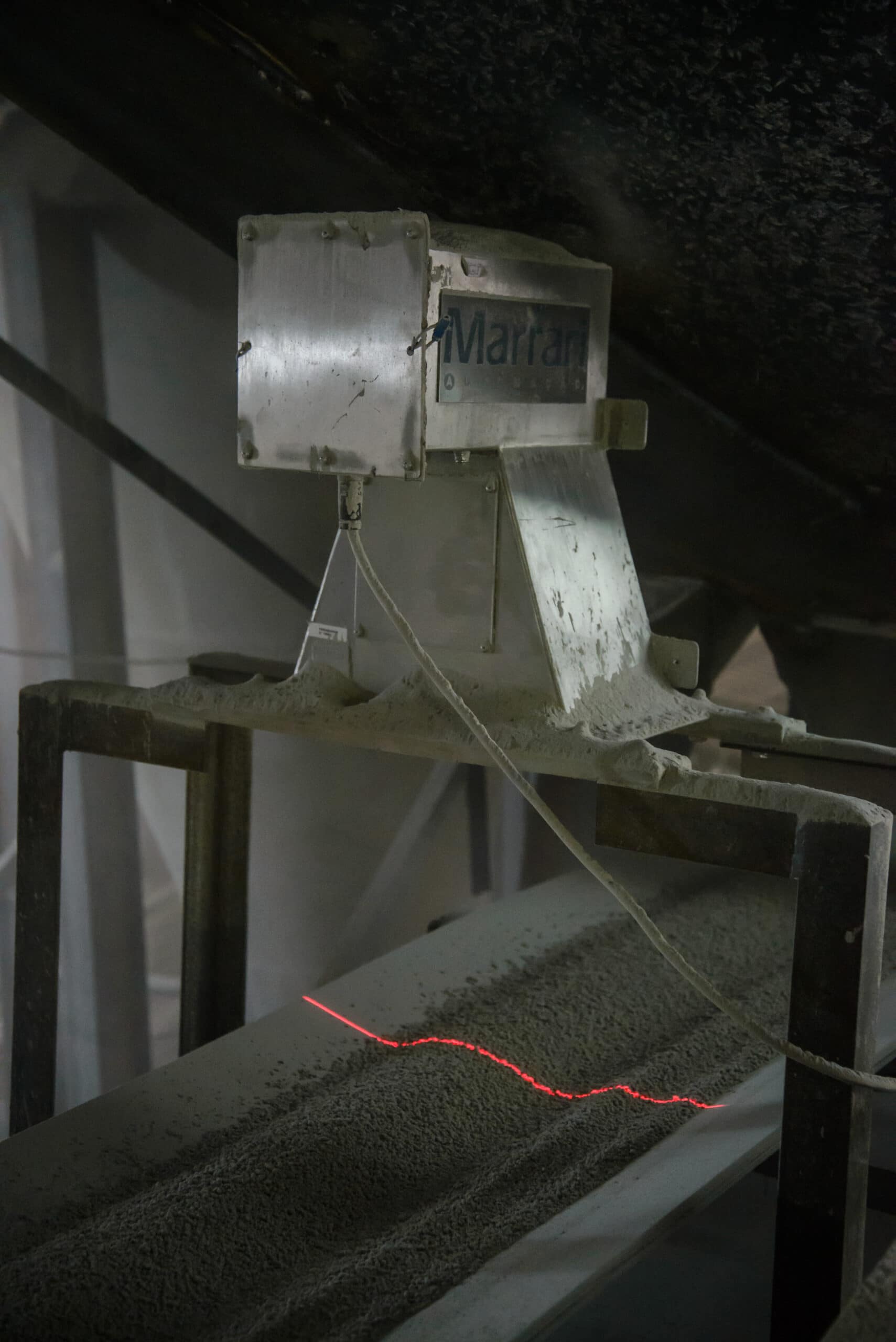

The Volume X in-line volume meter is a laser scanner that scans the profile of the load on conveyor belts to measure the volume and mass flow of the moving material.

It is a high-precision scanner that allows real-time measurement of the volume of transported material in various applications, such as mining, steelmaking, cement, fertilizers, food, among others.

The Volume X is a sensor based on laser barrier technology, using a laser to measure the height of the material on the conveyor belt. With this information, the system can calculate the volume of transported material and display the information in real-time on a display or integrate it into a production control or industrial supervisory system.

The sensor is designed to operate in extreme environments, enduring adverse conditions such as dust, vibration, humidity, and high temperatures without losing its precision. It is an effective solution to improve efficiency and safety in material transport operations on conveyors, ensuring that production meets specifications.

Why is Volume X essential for your process?

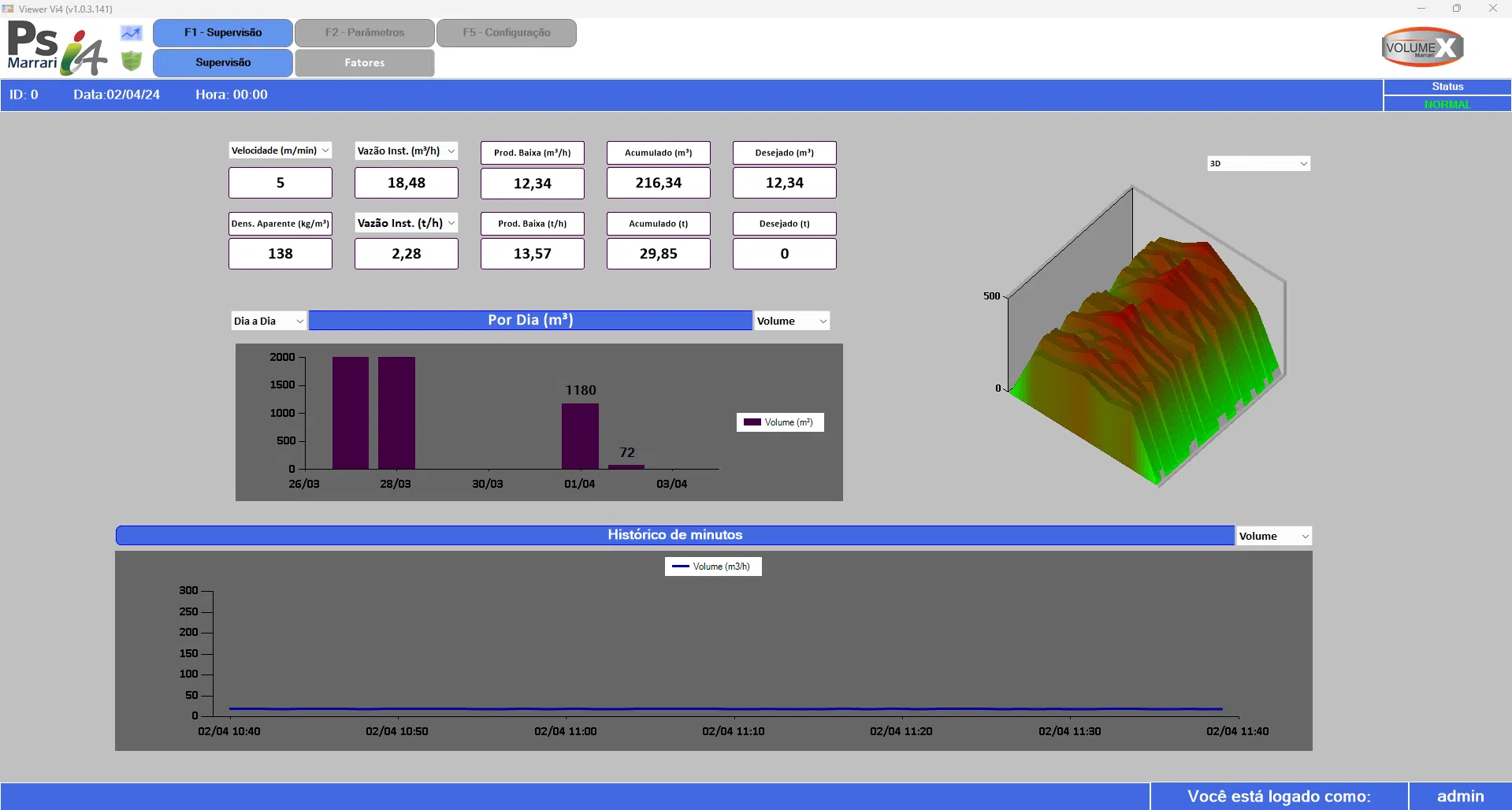

In addition to not requiring modifications to the transport line, it provides indispensable features to the process: instantaneous flow (m³/h), accumulated volume in the period (m³), conveyor speed (m/s), apparent density when coupled to an integrating scale, production achievement alerts, excess load on the conveyor, maximum and minimum product limits on the conveyor, conveyor deviations, and alerts for uneven load distribution on the conveyor.

AND WHAT OTHER FEATURES DOES IT OFFER FOR MANAGEMENT?

It provides data on process efficiency by generating OEE reports with information about operation times, downtime, utilization of load capacity, etc. This information is valuable for process adjustments and ensuring operational effectiveness.

Benefits of using a volume and mass flow control sensor:

- Improves measurement accuracy: The material volume sensor accurately measures the quantity of transported material, ensuring that production meets specifications.

- Reduces waste: With precise measurements, it is possible to avoid waste and reduce material costs.

- Increases efficiency: The sensor allows monitoring the material flow, detecting issues, and alerting operators to adjust production in real-time.

- Facilitates maintenance: With the sensor, it is possible to identify faults quickly and anticipate potential problems, avoiding unscheduled downtime.

- Increases safety: Monitoring the material flow enables the detection of possible obstructions, reducing the risks of accidents.

- Automates processes: With this sensor, the measurement of material volume is automated, reducing the need for human intervention and increasing process efficiency.

Benefits for the safety of your operation:

The Volume X, with its sensors, can identify deviations in rollers and conveyor belts, helping to prevent accidents and damage to workers and equipment. Deviations can result in conveyor malfunction, misalignment, material spills, and collisions, which can cause injuries and significant material damage. Causes may include maintenance issues, natural wear and tear, and weight overload, and companies should regularly perform preventive maintenance and monitor the performance of conveyor belts to ensure worker safety.

Moreover, the system goes beyond by monitoring conveyor belt rollers; it can bring various benefits to the process, such as reducing costs for repairs, maintenance, and compensation for injuries, improving the quality of transported products, extending the durability of associated equipment, and providing a safer working environment, increasing productivity. By identifying and correcting deviations in rollers, it is possible to ensure the proper functioning of the conveyor belt and prevent accidents, resulting in a more efficient and secure process.

AND WHY USE MARRARI EQUIPMENT?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss using methods such as OEE and Industry 4.0. This creates a more effective, productive, and modern production environment!

If you want to know more about us and news from the automation world, visit our blog, Facebook, or LinkedIn.

WARRANTY

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!