The in-line moisture meter for Sugarcane Bagasse, what is it?

The in-line moisture meter for sugarcane, UmiCana, is Marrari’s solution for real-time moisture measurement of sugarcane bagasse, and their derivatives passing through a conveyor belt or production line. It features a sensor with a capacitive active principle, meaning that the measurement is more accurate and faster than resistance-based methods.

Why use UmiCana in my production line?

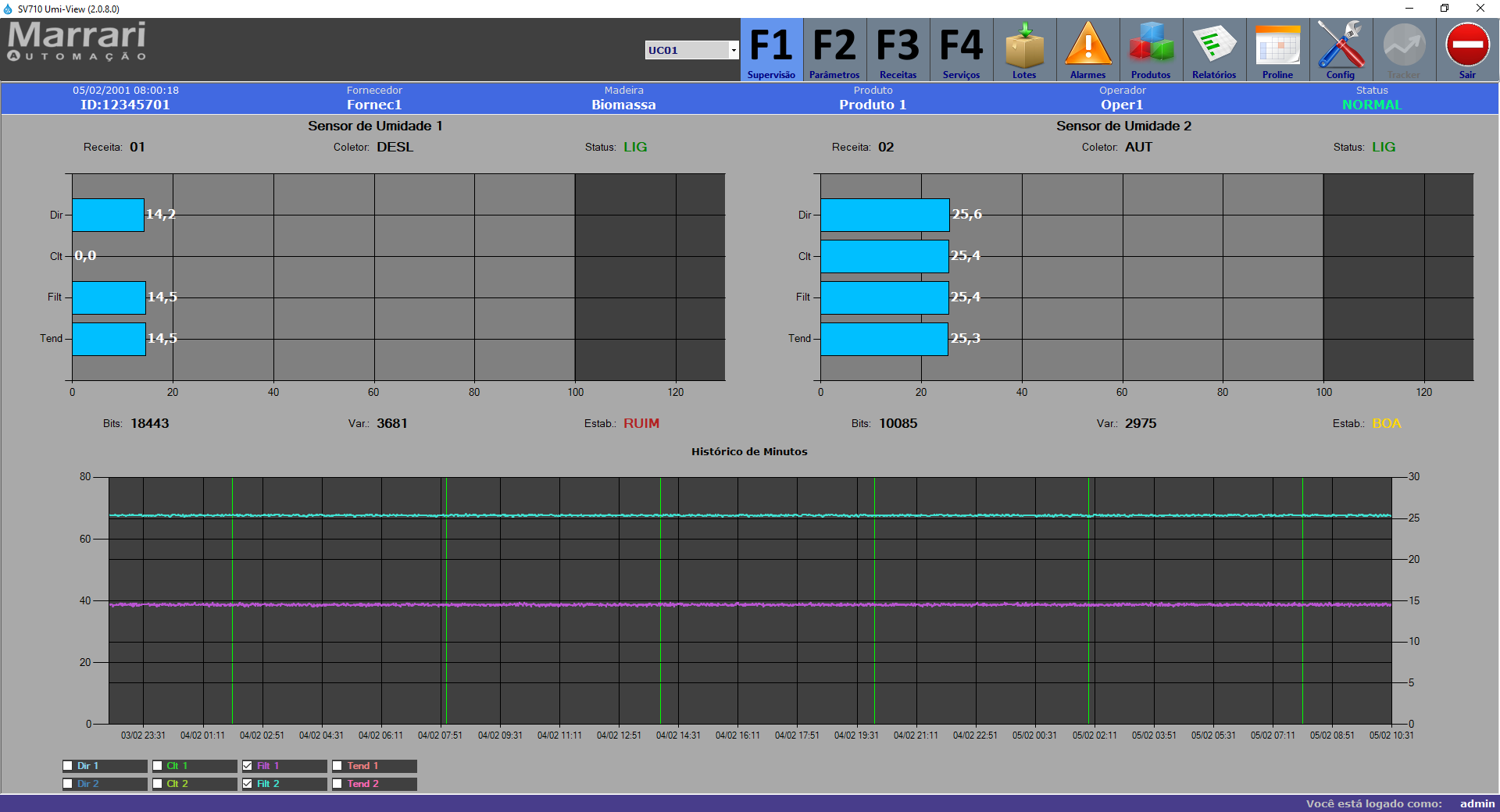

Knowledge of the moisture content of bagasse is crucial for two main reasons. First, it is an important indicator to determine if the extraction is correct and allows for adjustments to imbibition valves, ensuring maximum extraction. Second, the bagasse sent to the boiler should not have elevated moisture levels as there is a risk of ‘smothering’ the process, leading to instabilities in the process.

How does UmiCana work?

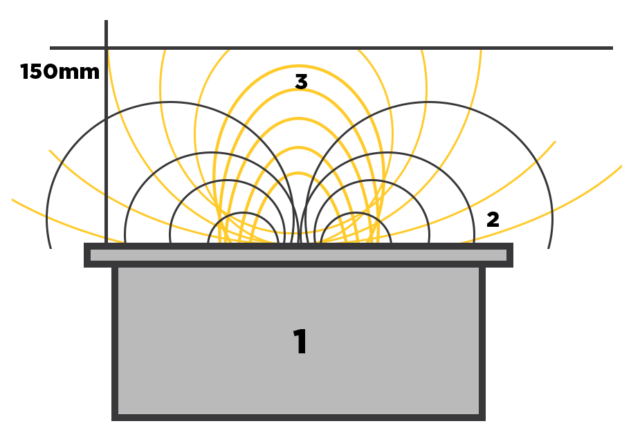

The moisture transducer is based on the capacitive principle. Its design allows for the assessment of the moisture content of the entire product, not just surface moisture.

Benefits of measuring bagasse and sugarcane moisture for sugarcane-energy industries:

- Optimization of Energy Production: Allows precise adjustments in the burning process, optimizing energy production from sugarcane bagasse.

- Efficiency in Steam Generation: Contributes to the efficiency of steam generation in boilers, ensuring that the bagasse is in the ideal condition for steam production.

- Fuel Quality Control: Facilitates control of the quality of bagasse used as fuel, avoiding issues such as incomplete combustion and reducing residue formation.

- Fuel Savings: By ensuring that the bagasse has the correct moisture content, it avoids the waste of energy associated with excess moisture, resulting in fuel savings.

- Reduction of Operational Costs: Minimizes operational costs by avoiding inefficient fuel use and optimizing process efficiency.

- Increased Energy Efficiency: Contributes to a higher overall energy efficiency of the plant by ensuring that bagasse is burned efficiently.

- Prevention of Operational Issues: Quickly identifies variations in bagasse moisture, preventing operational problems such as deposit formation and equipment obstructions.

- Environmental Compliance: Helps maintain compliance with environmental regulations, reducing unnecessary emissions during the burning of bagasse.

- Enhanced Operational Safety: Contributes to operational safety by ensuring that bagasse is within safe parameters for facility operation.

- Improvement in Cogeneration Quality: Positively impacts the cogeneration of electrical energy, as the proper moisture content of bagasse directly influences process efficiency.

In summary, real-time measurement of bagasse moisture offers a range of advantages, from optimizing energy production to cost reduction and compliance with environmental standards, contributing to the overall efficiency of operations in the sugarcane-energy sector.

How does UmiCana manage to be PRECISE?

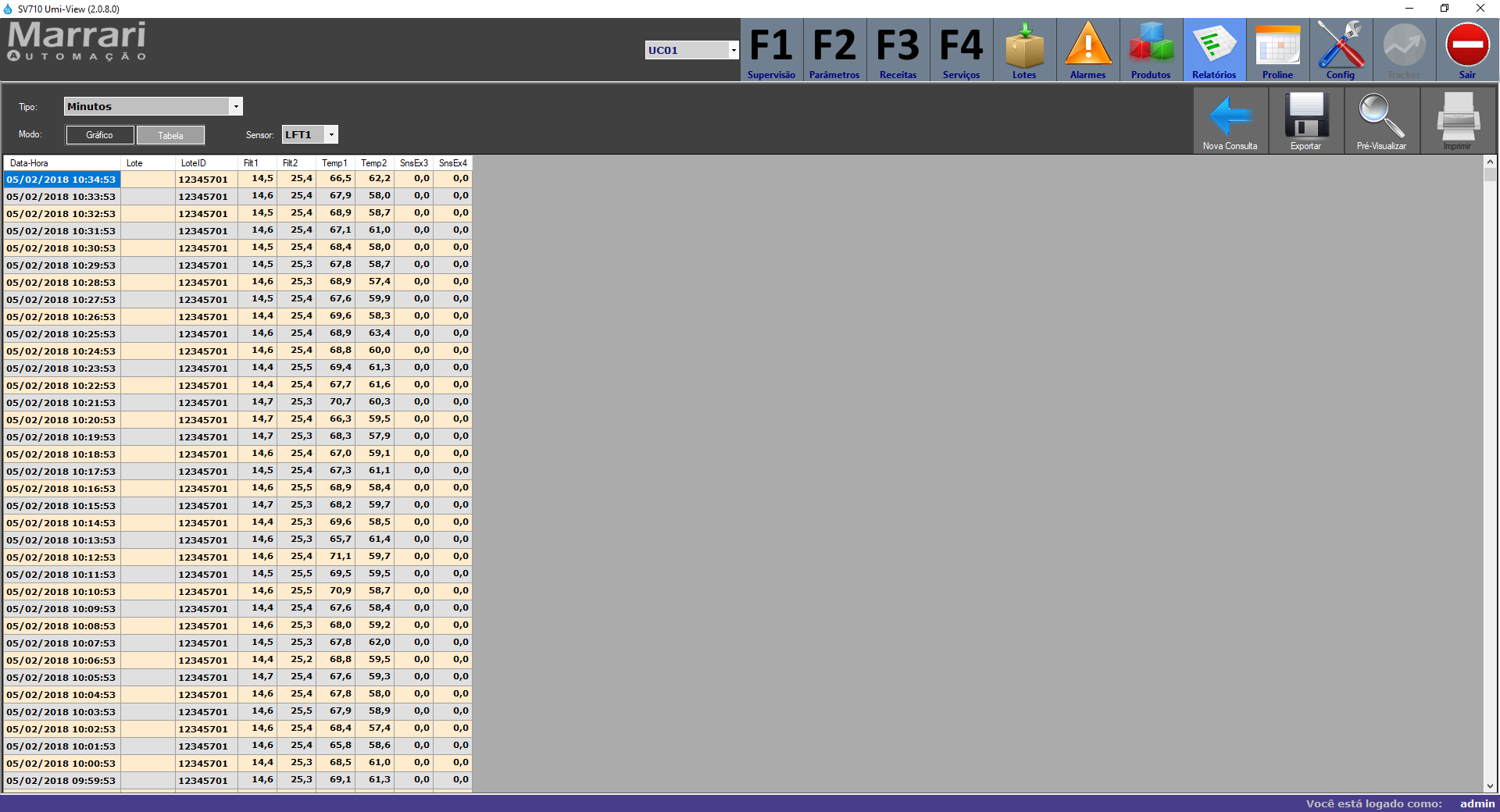

The sensor works with the capacitive method, as it is, a sensor is installed on the mat, conveyor, dryer, or other location and as soon as it is loaded, the sensor (1) passes and the product is illuminated second by second in a field with a height of 150mm (2 and 3). So I have a real measurement of the integrity of the entire material, not just superficially.

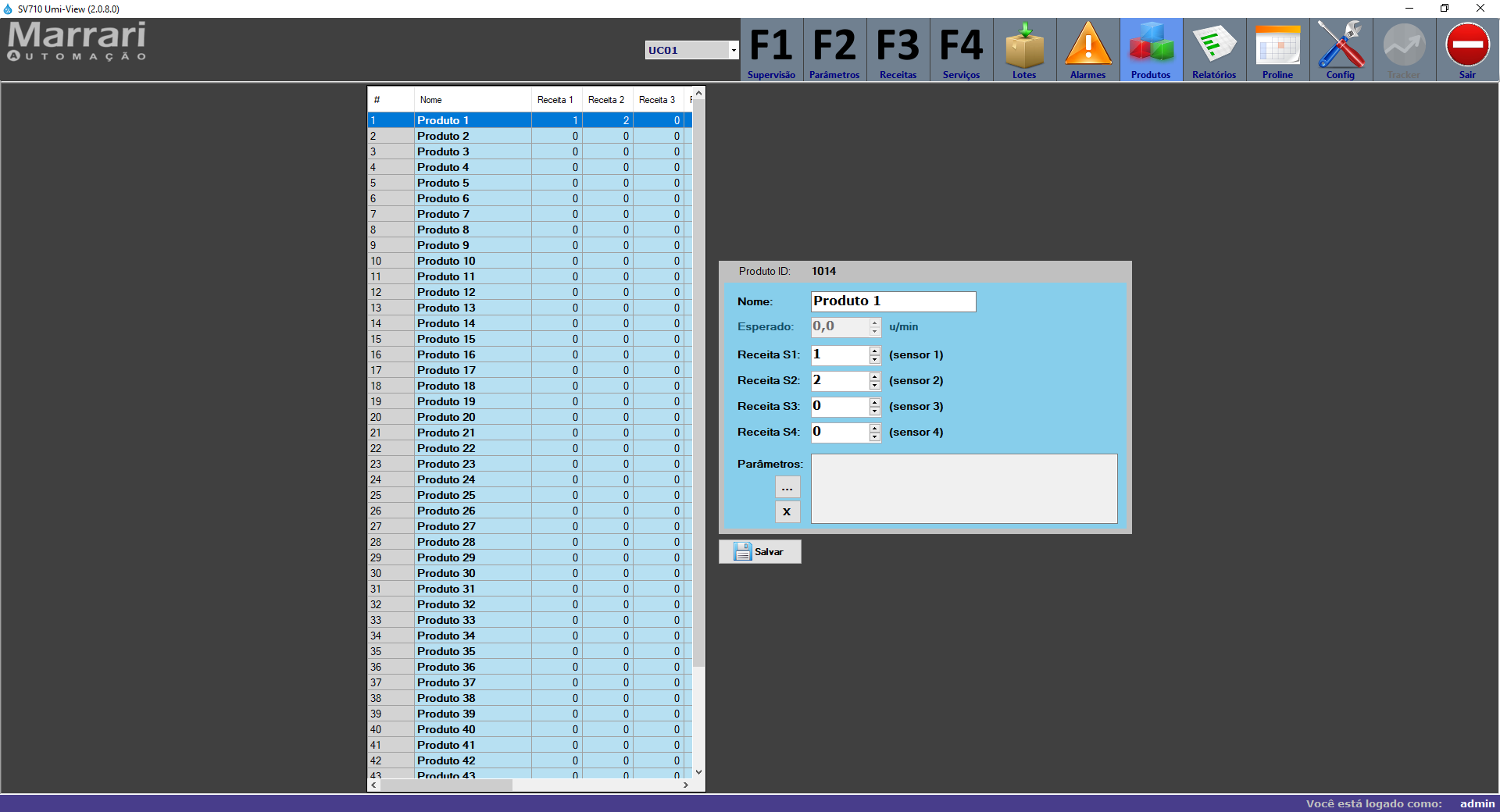

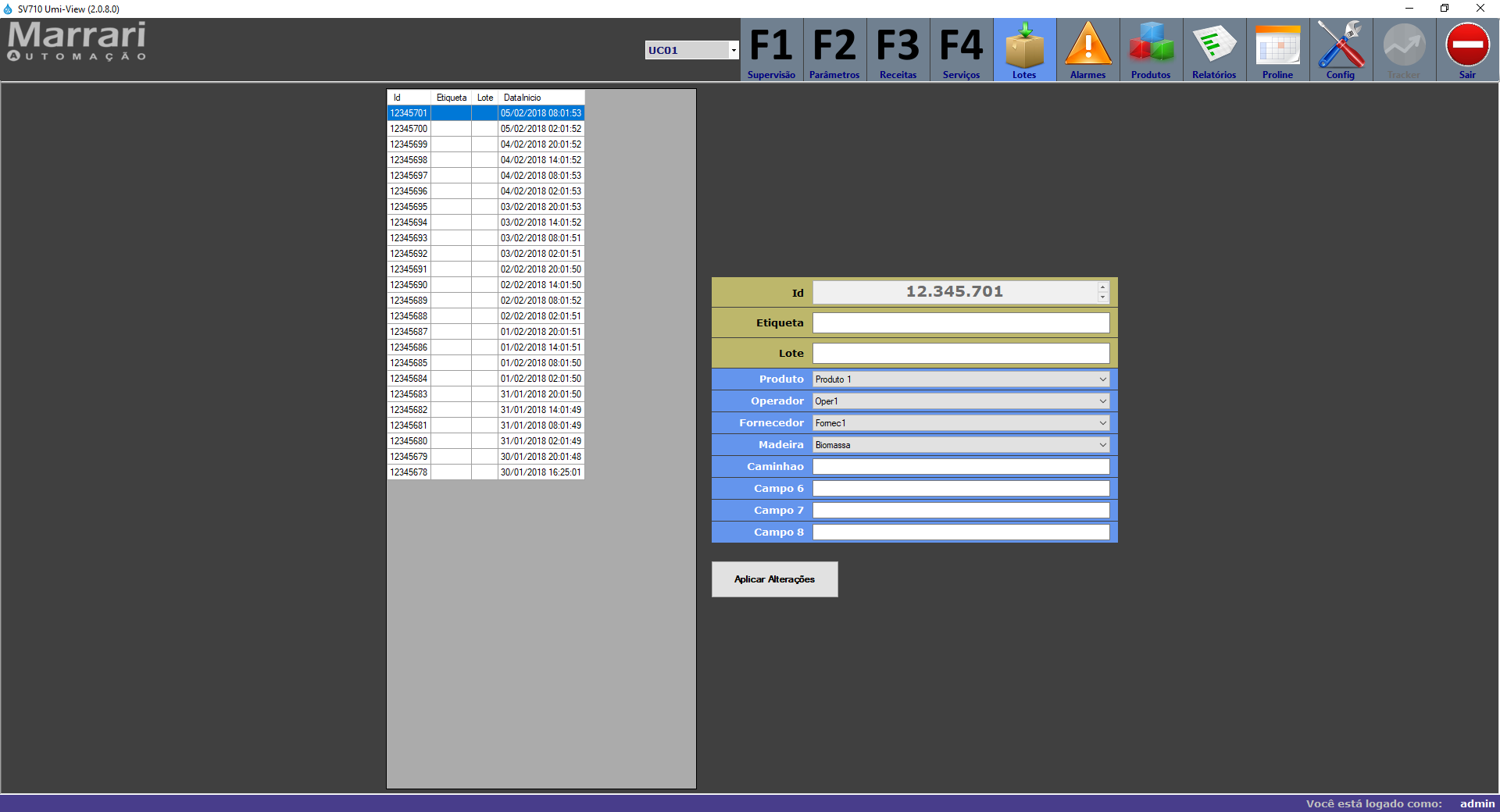

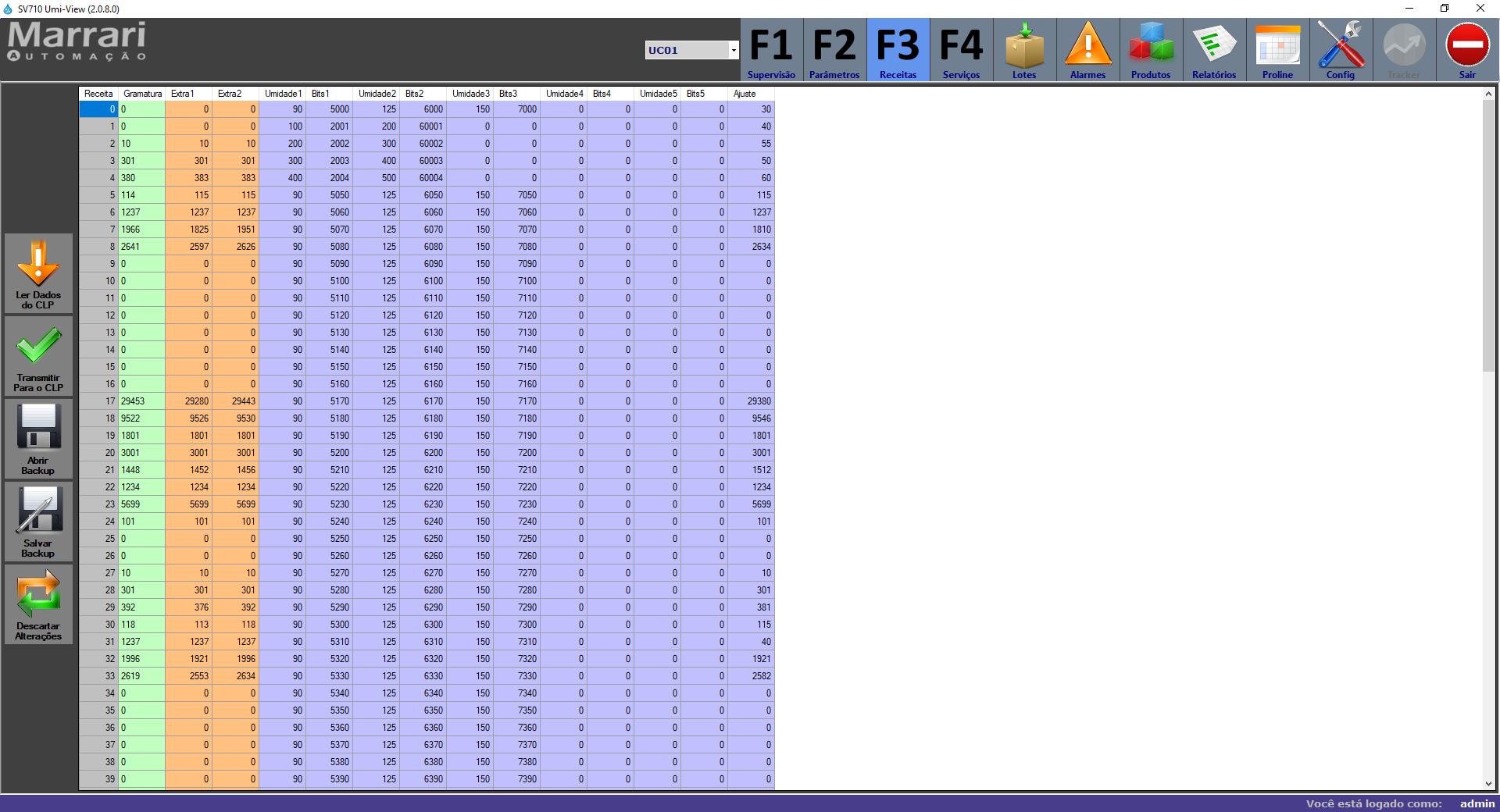

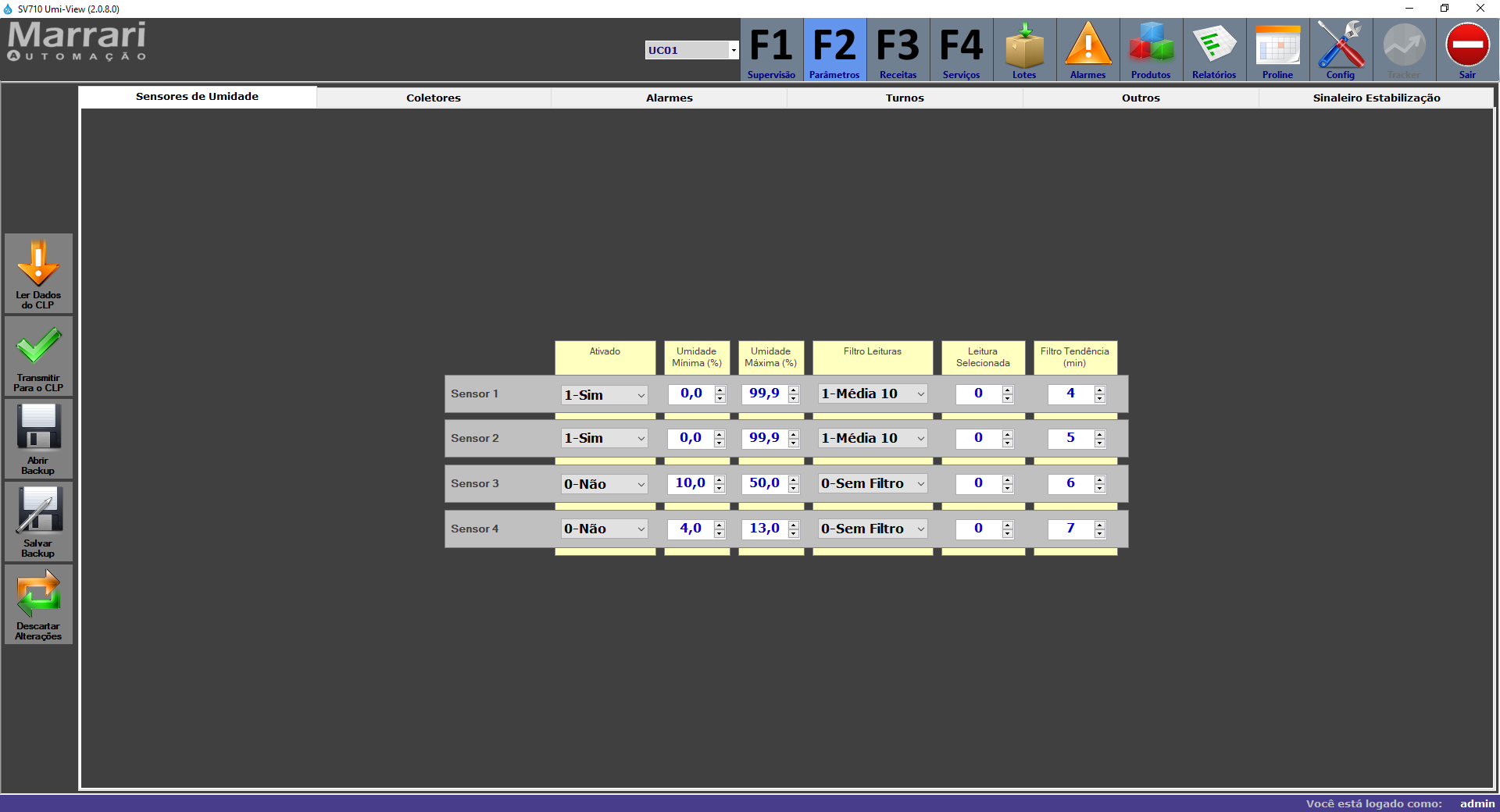

It also uses a calibration method based on recipes. In essence, you use the Tracker (equipment that comes with UmiCana) to collect samples throughout the day and compare them with the laboratory results.

If there are discrepancies, you can go to the Tracker’s included software and update the values to match the laboratory assay, thus ensuring its precision.

If I want to purchase the meter with a ready recipe for my product?

Simply send a sample of your product to us at Marrari, specifically to Umilab, where we will create a specific recipe for you based on laboratory analysis!

Contact us to learn more!

And why choose Marrari equipment?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss using methods such as OEE and Industry 4.0, thereby creating a more effective, productive, and modern production environment!

If you want to learn more about us and stay updated on automation news, visit our blog, Facebook, or LinkedIn.

Warranty:

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is as productive as possible!