What is the in-line moisture meter for Umichip biomass?

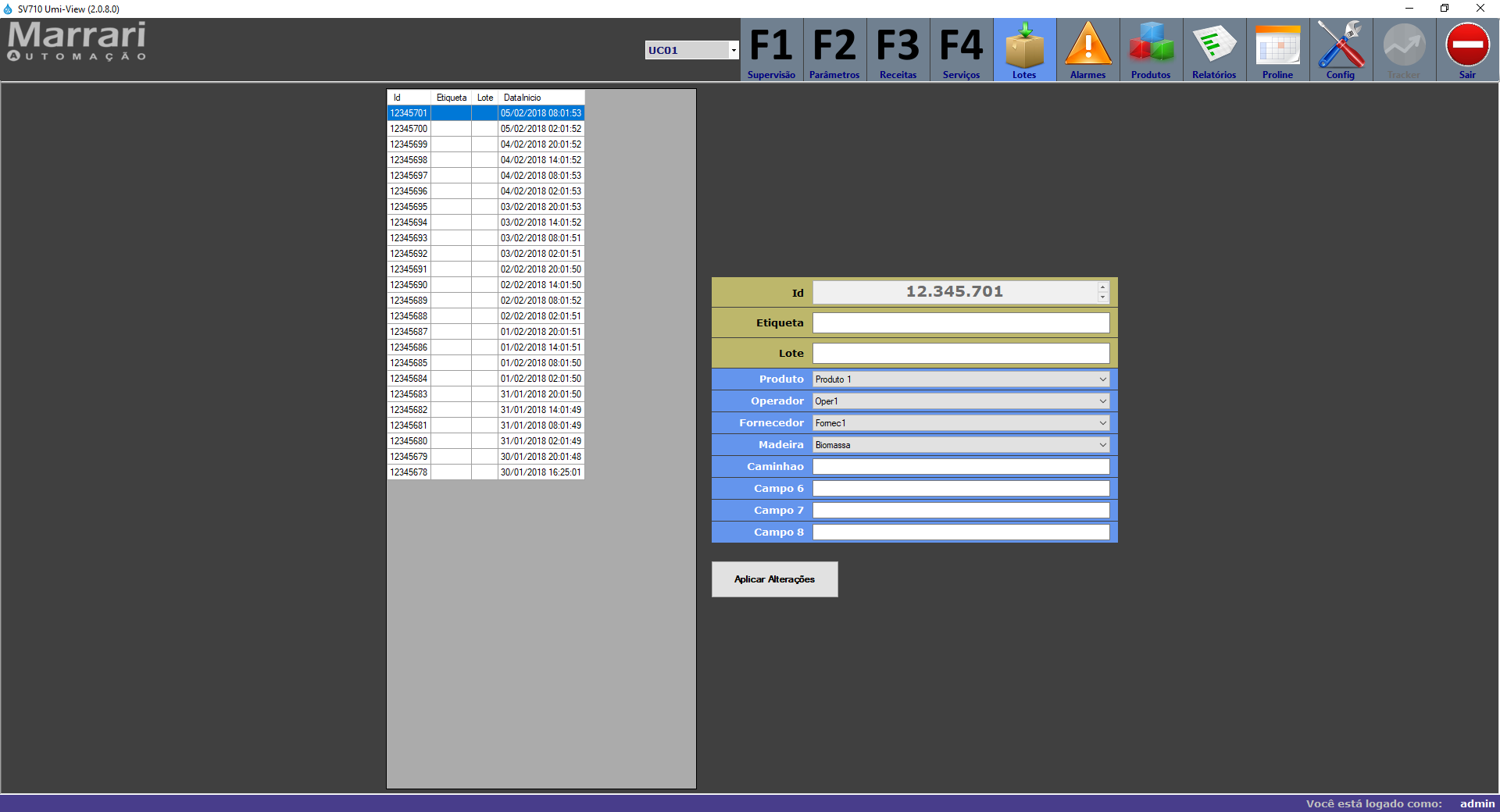

The In-line Moisture Meter for Biomass, known as Umichip, represents Marrari’s advanced solution for in-line measurement systems dedicated to analyzing moisture content in biomass and a variety of other materials in production processes. This innovation is particularly relevant for industries that incorporate biomass in their processes, such as pulp production or energy generation through boilers and heaters.

Umichip uses robust transducers based on the dielectric stiffness analysis of the medium, ensuring exceptional performance. This measurement system is not limited to the material surface, offering comprehensive analyses of the entire biomass in question. With Umichip, you gain accurate real-time information about biomass moisture, enabling significant improvements in the efficiency of your production processes and the management of your biomass measurement system.

Why use Umichip?

Accurate measurement of biomass moisture for boilers plays a central role in maintaining the quality of your material or product while directly impacting energy efficiency. For example, consider transporting biomass chips on a conveyor belt to be burned in a boiler to generate energy. When the chips are excessively moist, the boiler needs to expend additional energy to evaporate the water in the material before ignition and, consequently, energy generation.

In this context, an in-line moisture meter becomes an essential tool, capable of calculating the Lower Heating Value (LHV) in real-time, provided this functionality is incorporated. In other words, it provides instant information about the amount of energy your boiler will be able to generate with the transported material. This not only optimizes the energy efficiency of the system but also ensures effective and cost-efficient energy production.

How does the Umichip moisture measurement system for biomass work?

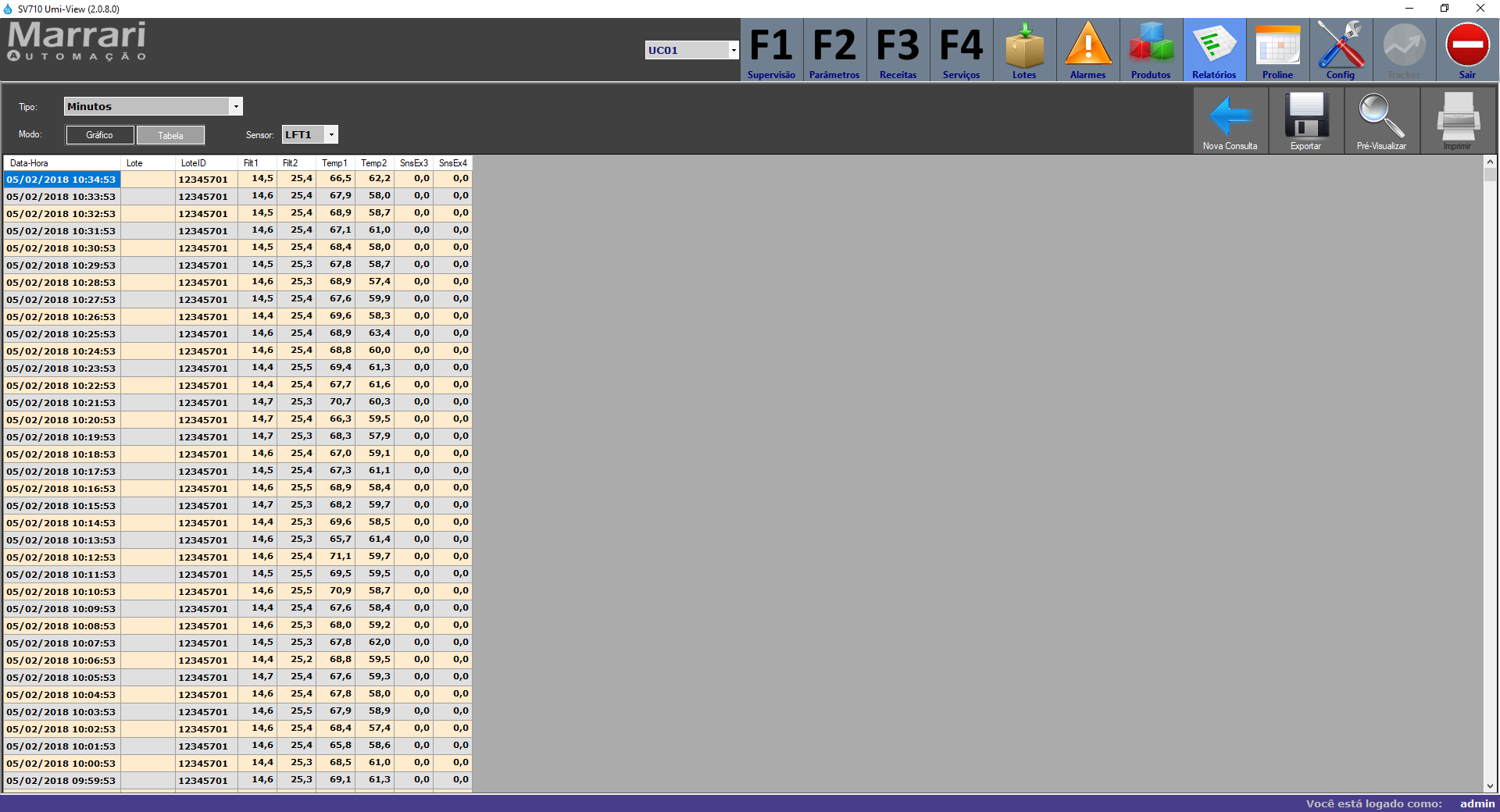

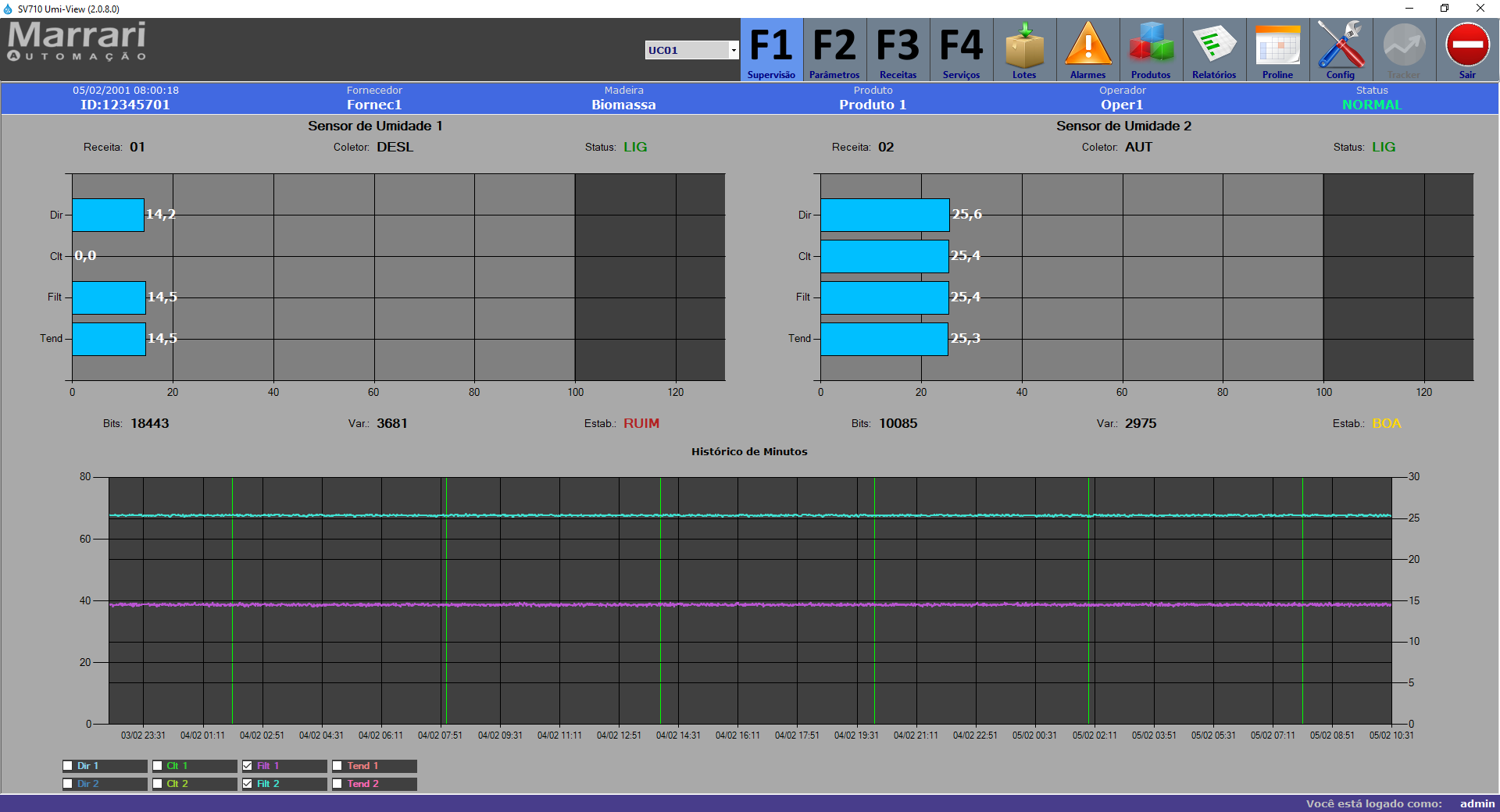

This system operates through dielectric reading, where a sensor is installed on the conveyor belt. As the material is transported by the belt, it passes directly over the sensor, which reads the product’s moisture every second. This provides a real-time measurement of moisture with exceptional accuracy, not only on the material surface but also in the interior.

How does UmiGrain manage to be SO ACCURATE?

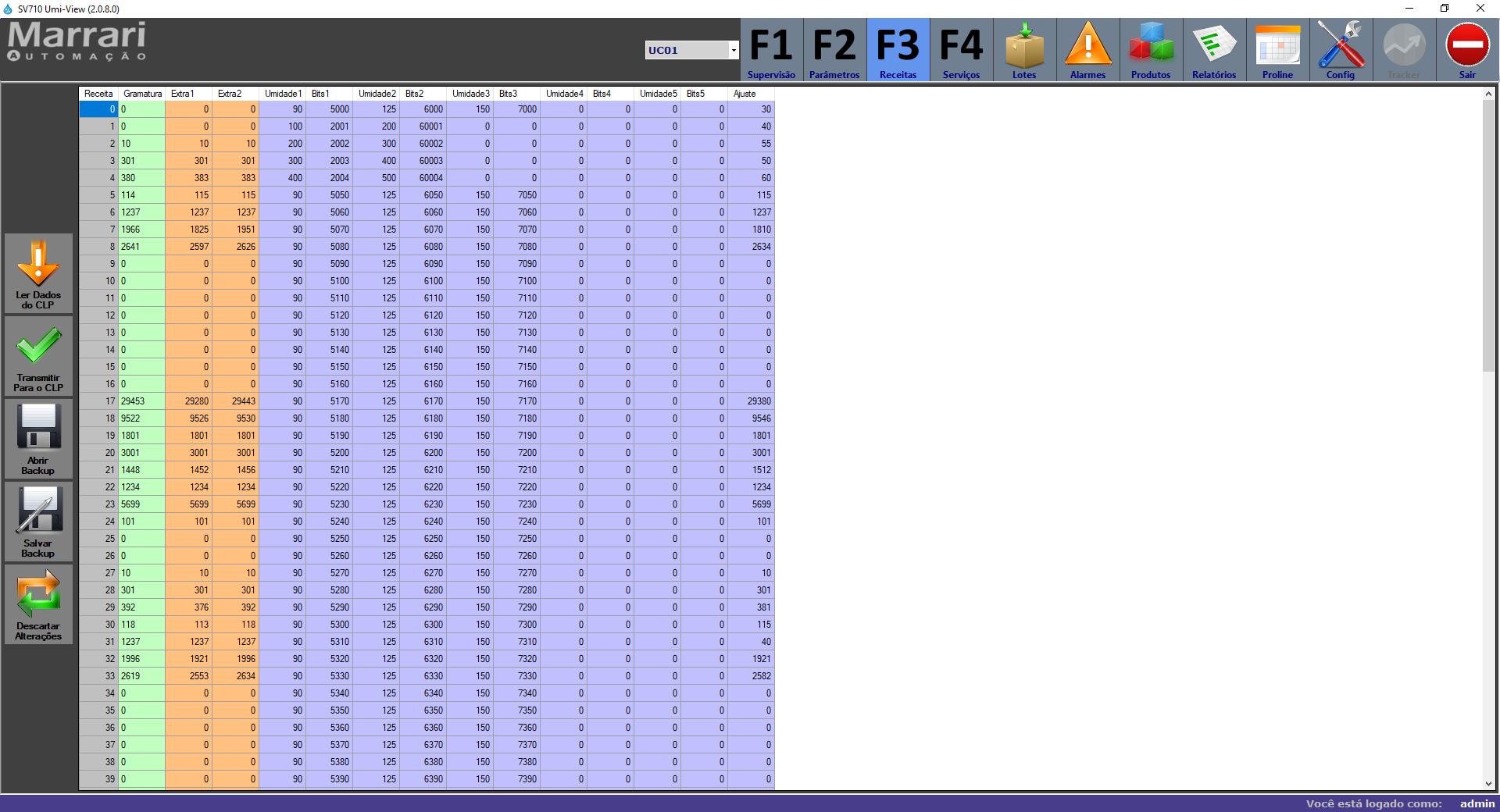

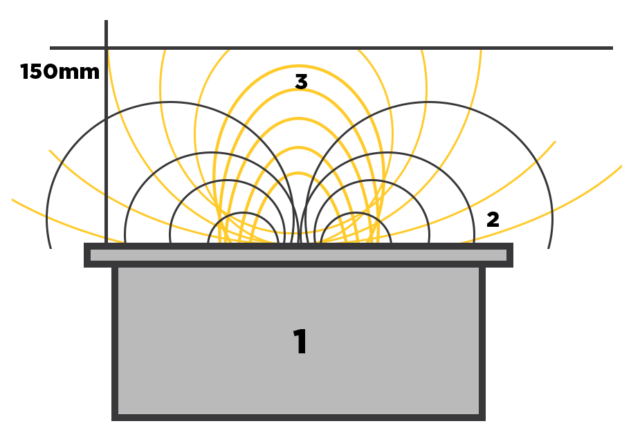

The sensor works using the capacitive method, that is, a sensor is installed on the conveyor belt, dryer, boiler or other location and while the biomass is being loaded, it passes through the sensor (1) and the moisture content of the product is read second by second in a height field of up to 150 mm (2 and 3). Thus, there is a real measurement of the moisture content of the entire material, not just superficially.

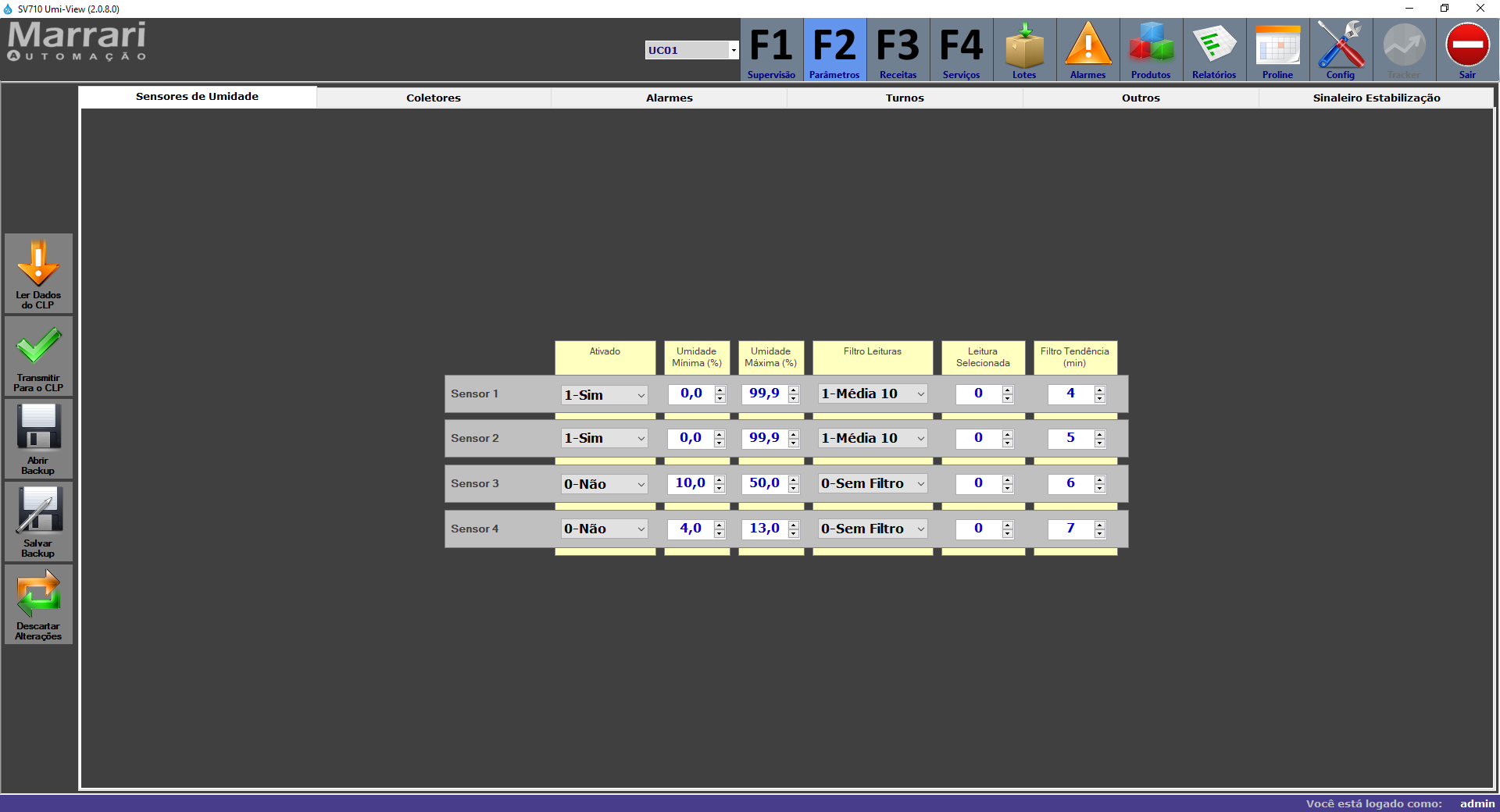

Accuracy is guaranteed by several critical factors, including sensor stability, a high sampling rate, and highly precise calibration curves. Additionally, the Tracker software is integrated into the system, allowing constant improvement of calibration curves, contributing to maintaining result accuracy over time.

Benefits of using a biomass moisture measurement sensor for boiler feeding:

- Precise Moisture Control: The in-line moisture meter allows precise control of fuel moisture, helping to avoid issues such as incomplete combustion, residue formation, and excessive emissions.

- Fuel Savings: With precise moisture control, it’s possible to optimize fuel consumption and avoid excess fuel, leading to cost savings.

- Energy Efficiency: Again, with precise moisture and LHV control, the boiler can operate more efficiently, maximizing energy production from the fuel.

- Reduced Maintenance Costs: Using the in-line moisture meter can help reduce boiler maintenance costs by avoiding issues such as deposit formation and corrosion caused by excess moisture.

- Enhanced Safety: The in-line moisture meter can help ensure that the fuel meets necessary safety standards for boiler operation, helping to prevent accidents and ensure the safety of operators and equipment.

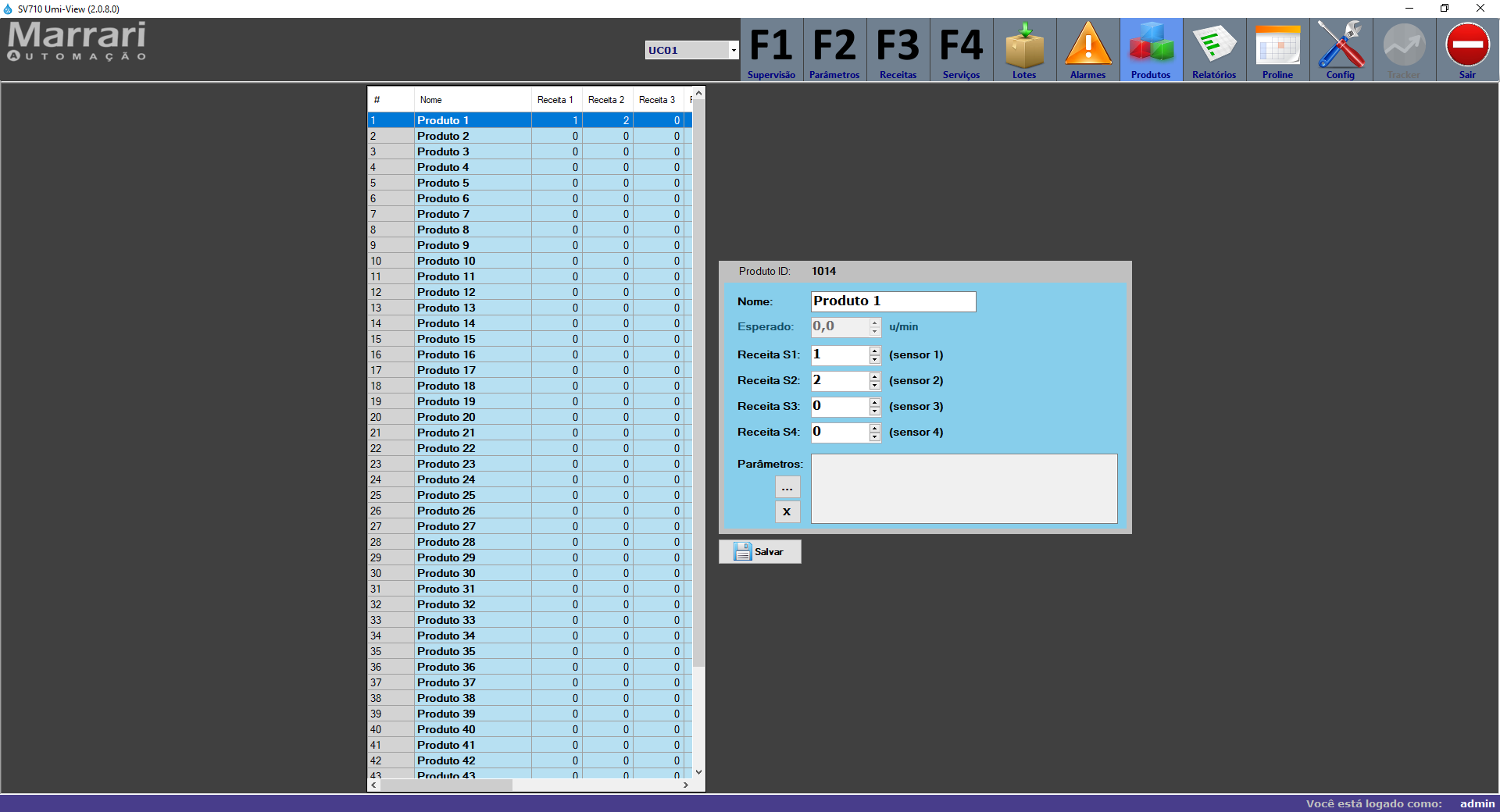

IF I WANT TO PURCHASE THE METER WITH A READY RECIPE FOR MY PRODUCT?

Simply send a sample of your product to us at Marrari, specifically to Umilab, where we will create a specific recipe for you according to laboratory testing!

Contact us to learn more!

AND WHY USE MARRARI EQUIPMENT?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss using methods such as OEE and Industry 4.0. This creates a more effective, productive, and modern production environment!

If you want to learn more about us and automation news, visit our blog, Facebook, or LinkedIn.

GUARANTEE

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!