WHAT IS THE IN-LINE MOISTURE METER FOR umipet FEED?

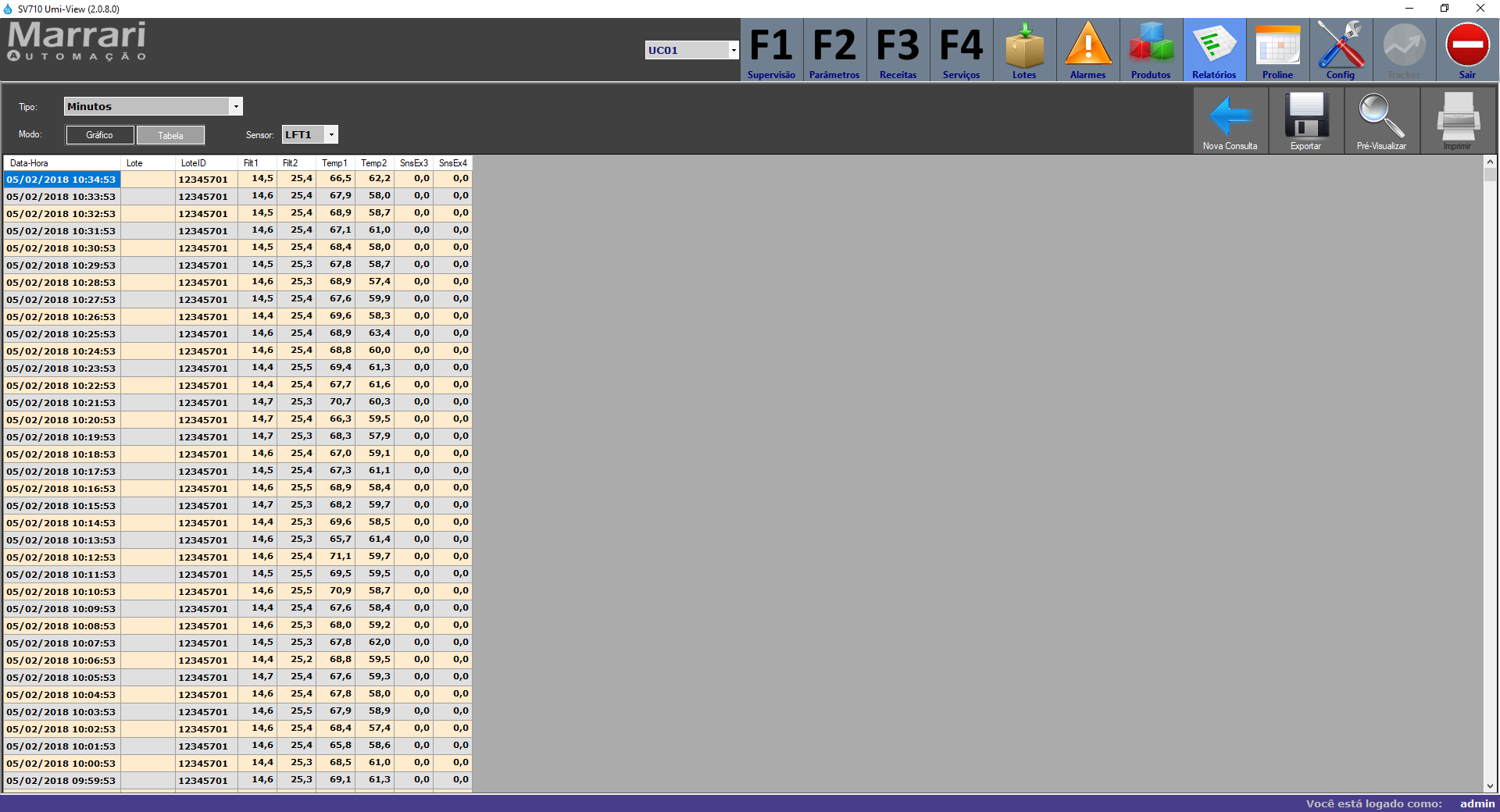

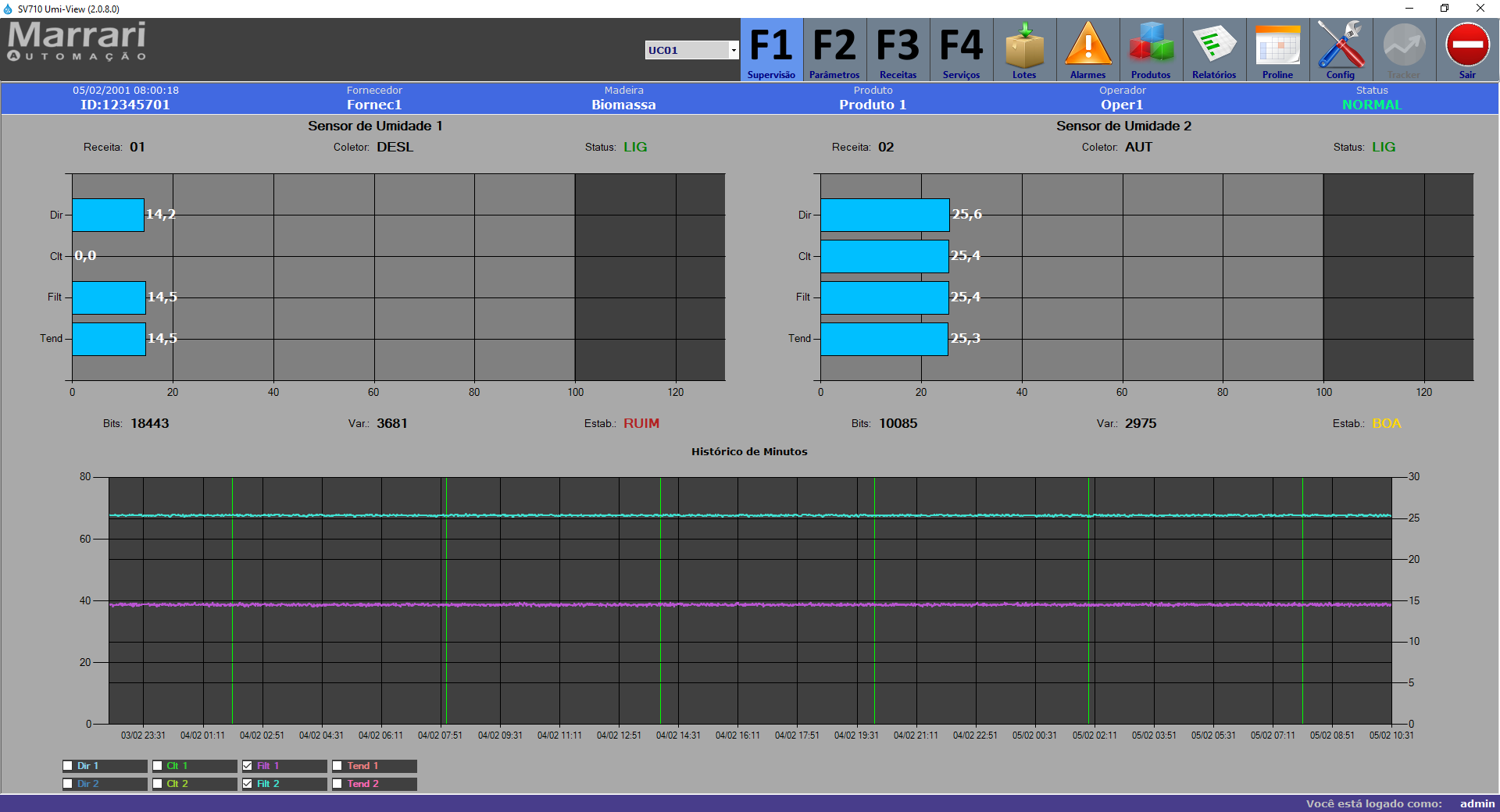

The UmiPet moisture meter is Marrari’s solution for animal feed production lines, measuring real-time moisture content through a capacitive sensor installed at the exit of the drying system.

WHY USE umipet IN MY PRODUCTION LINE?

Because the product’s moisture content directly influences the quality of the feed. Excessive moisture causes the feed to deteriorate during storage, leading to losses for the brand. With very low moisture content, dried grains and other raw materials for feed formulation compromise the product’s quality.

Benefits of controlling moisture during the animal feed production process:

- Nutritional Quality: Precise moisture control allows for the formulation and production of feeds with consistent nutritional content, ensuring that animals receive the necessary nutrients for healthy growth.

- Palatability: Adequate moisture in the feed can influence palatability, directly affecting animal consumption. Maintaining moisture within ideal parameters contributes to the acceptance of the feed by animals.

- Production Consistency: Real-time moisture control helps maintain consistency in production, avoiding undesirable variations that may occur throughout the feed manufacturing process.

- Storage and Durability: Controlled moisture influences the stability and durability of the feed. Inadequate moisture levels can lead to deterioration and the growth of unwanted microorganisms, compromising the quality of stored feed.

- Production Efficiency: Continuous moisture monitoring allows real-time adjustments in the production process, optimizing operational efficiency and reducing ingredient waste.

- Production Cost: Precise moisture control helps prevent ingredient waste and reduce production costs, ensuring that only the necessary amount of water is added to the feed.

- Animal Health: Feed quality plays a fundamental role in animal health. Inadequate moisture in the feed can lead to storage problems, deterioration, and, consequently, affect the health of animals.

- Compliance with Regulations: In some cases, there are specific regulations related to moisture content in animal feeds. Monitoring and controlling moisture in real-time helps ensure compliance with these regulations.

- Loss Reduction: Avoiding significant moisture variations during production minimizes losses of raw materials and ingredients, contributing to more sustainable and economical production.

- Food Safety: Keeping moisture under control is essential to ensure food safety, preventing the growth of pathogenic microorganisms that can arise in conditions of high humidity.

In summary, real-time moisture control in the production of animal feeds offers a range of benefits, from improving nutritional quality to operational efficiency and compliance with regulations. These aspects are crucial to promoting animal health, reducing costs, and ensuring safety and consistency in feed production.

HOW DOES umipet WORK?

The moisture transducer is based on the capacitive principle. Its principle allows the evaluation of the moisture content of the entire product, not just surface moisture.

HOW IS umipet SO ACCURATE?

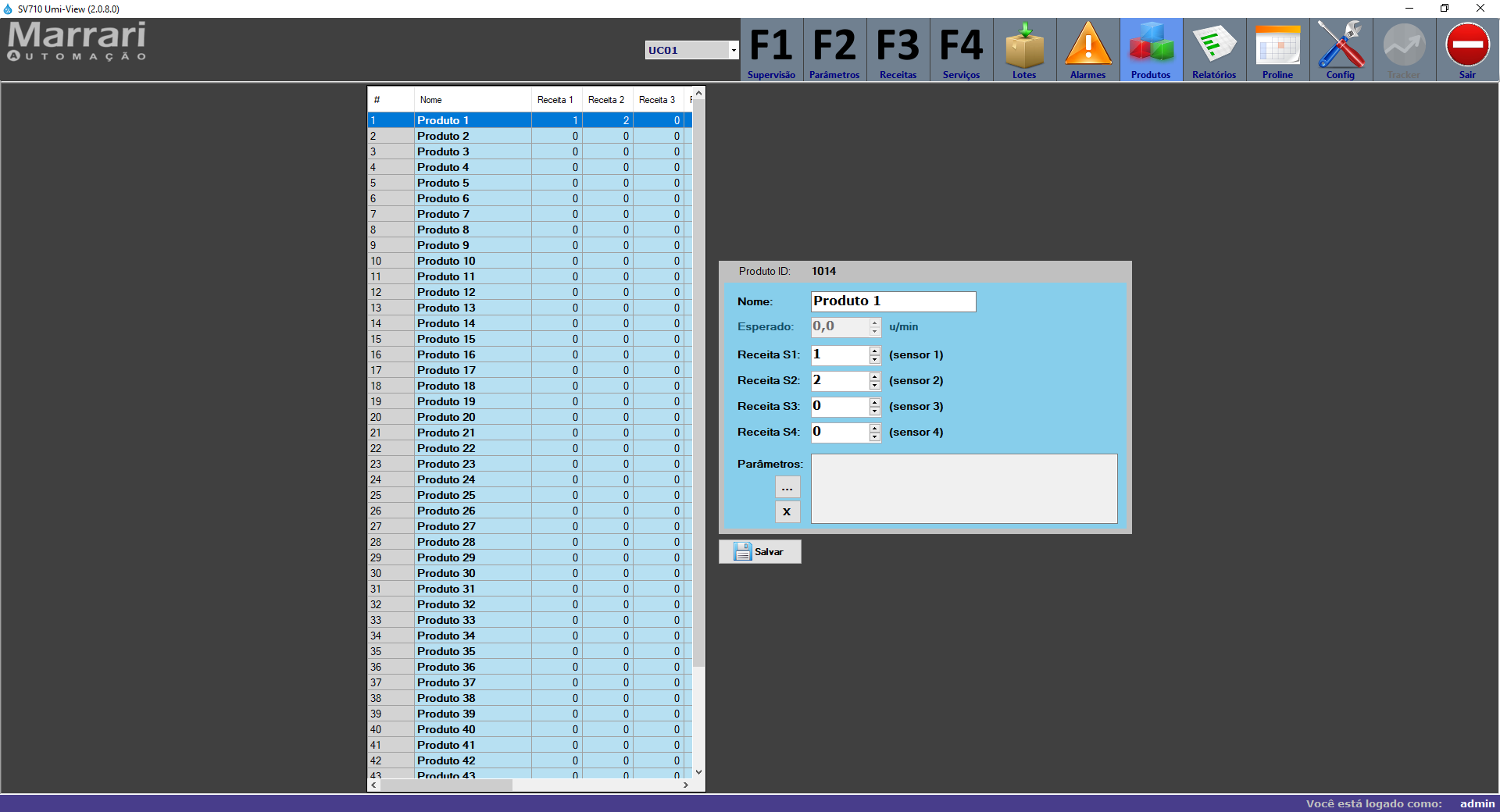

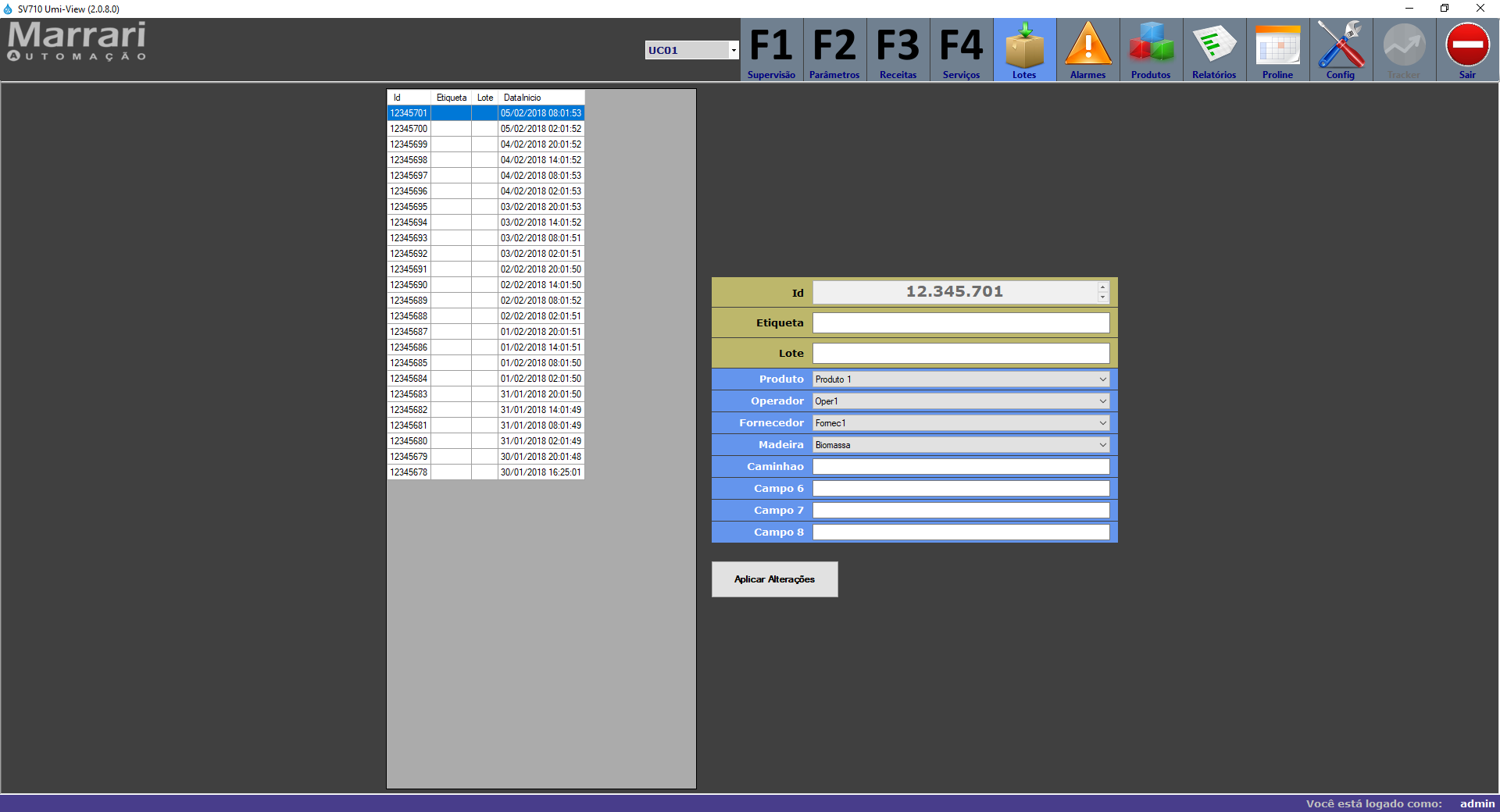

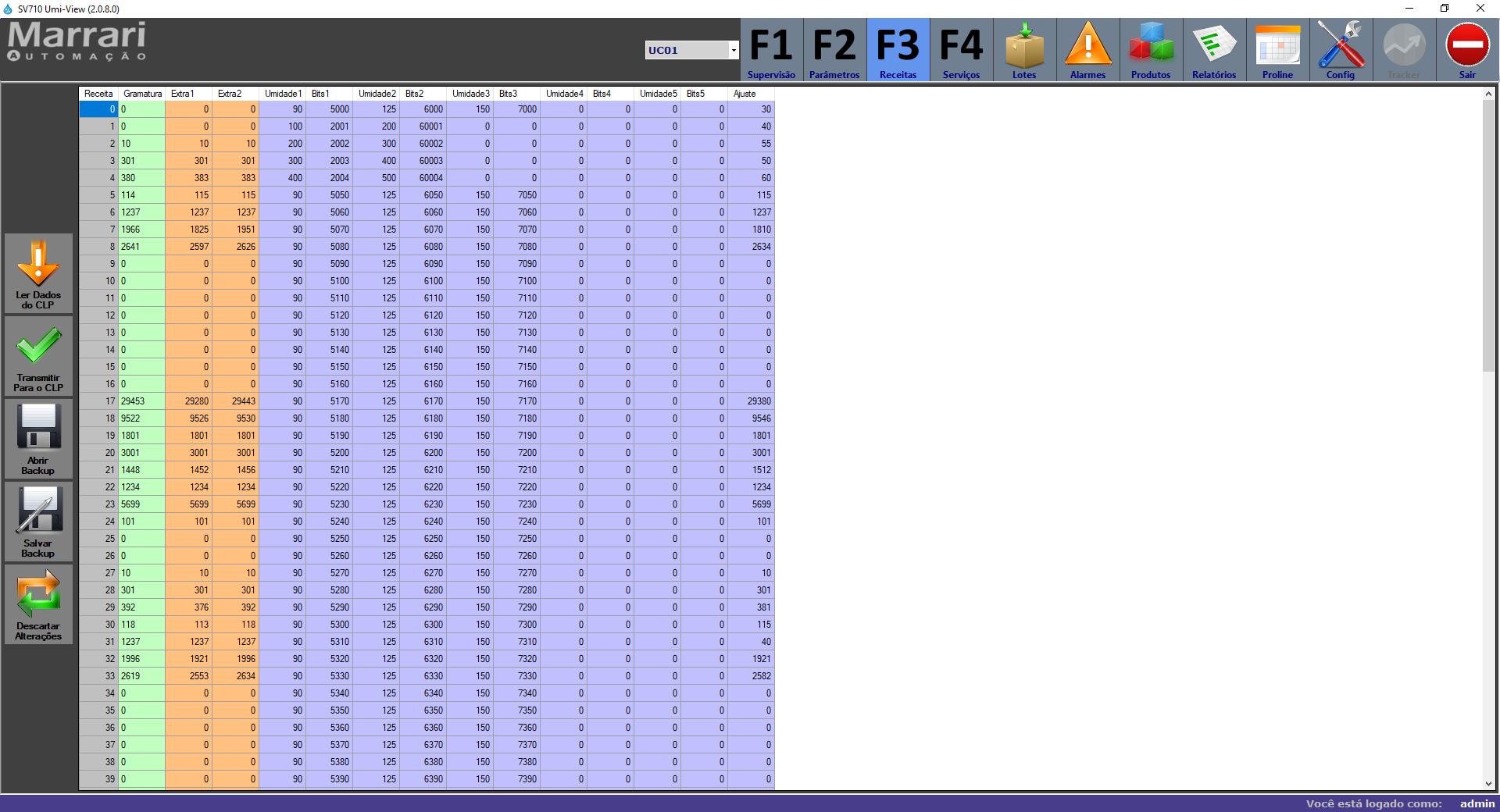

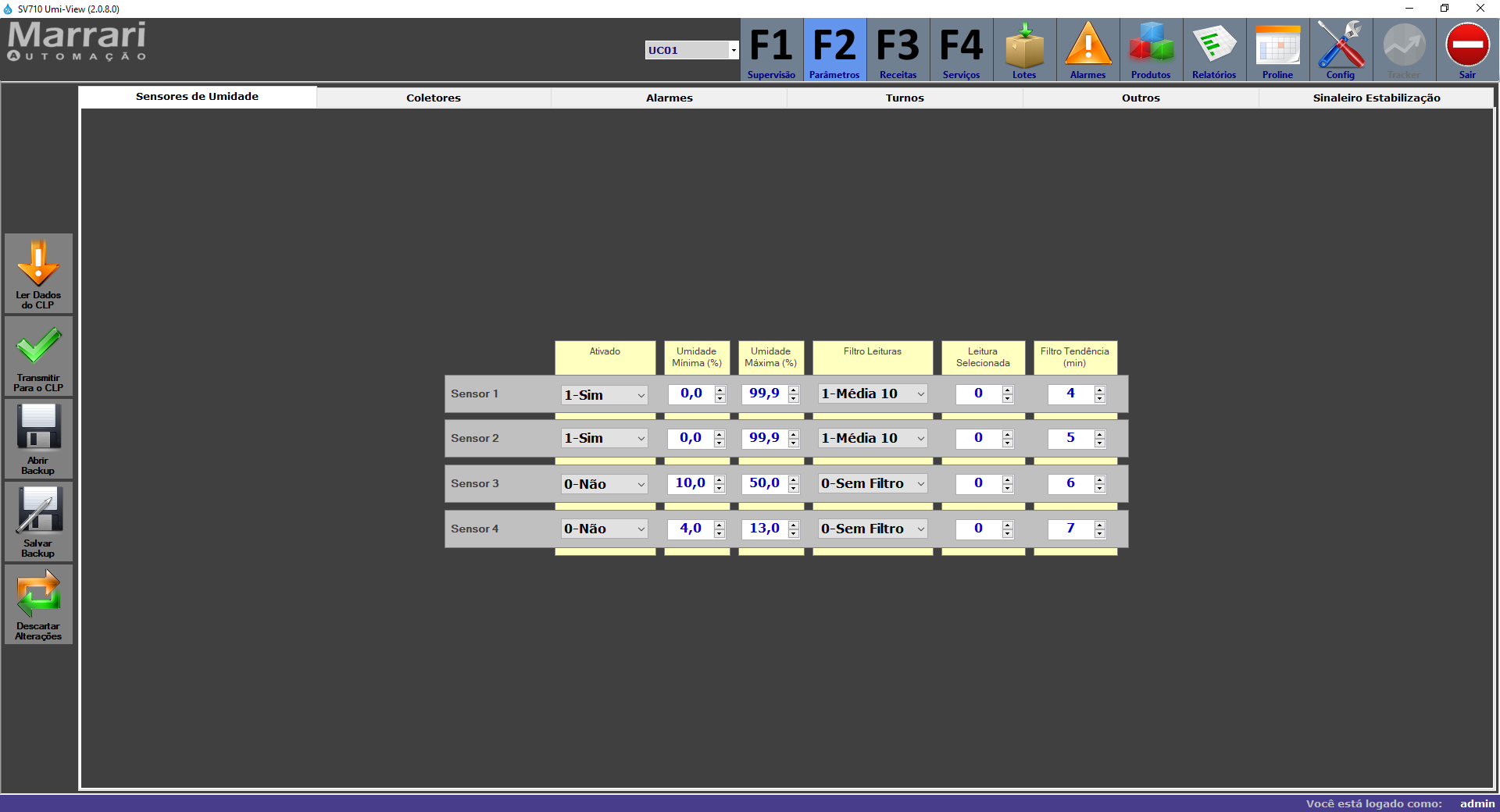

It uses a calibration method based on recipes. In short, you use the Tracker (equipment that comes with the UmiPet) to collect samples during the day and compare them with the laboratory.

If there are discrepancies, you can use the included Tracker software to update the values to match the laboratory test, thus ensuring its accuracy.

IF I WANT TO BUY THE MOISTURE METER WITH A PRESET RECIPE FOR MY PRODUCT?

Simply send a sample of your product to us at Marrari. More specifically, to Umilab, where we will create a specific recipe for you according to the laboratory!

Contact us to learn more!

WHAT WOULD BE ONE OF THE BIGGEST ADVANTAGES OF THE IN-LINE MOISTURE METER for umipet FEED?

It is being nationally produced! This means that maintenance is quick, practical, and inexpensive for all equipment!

AND WHY USE MARRARI EQUIPMENT?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss using methods such as OEE and Industry 4.0. Thus, creating a more effective, productive, and modern production environment!

If you want to know more about us and news from the automation world, visit our blog, Facebook, or LinkedIn.

GUARANTEE

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!