WHAT IS THE UmiMate MOISTURE METER FOR YERBA MATE?

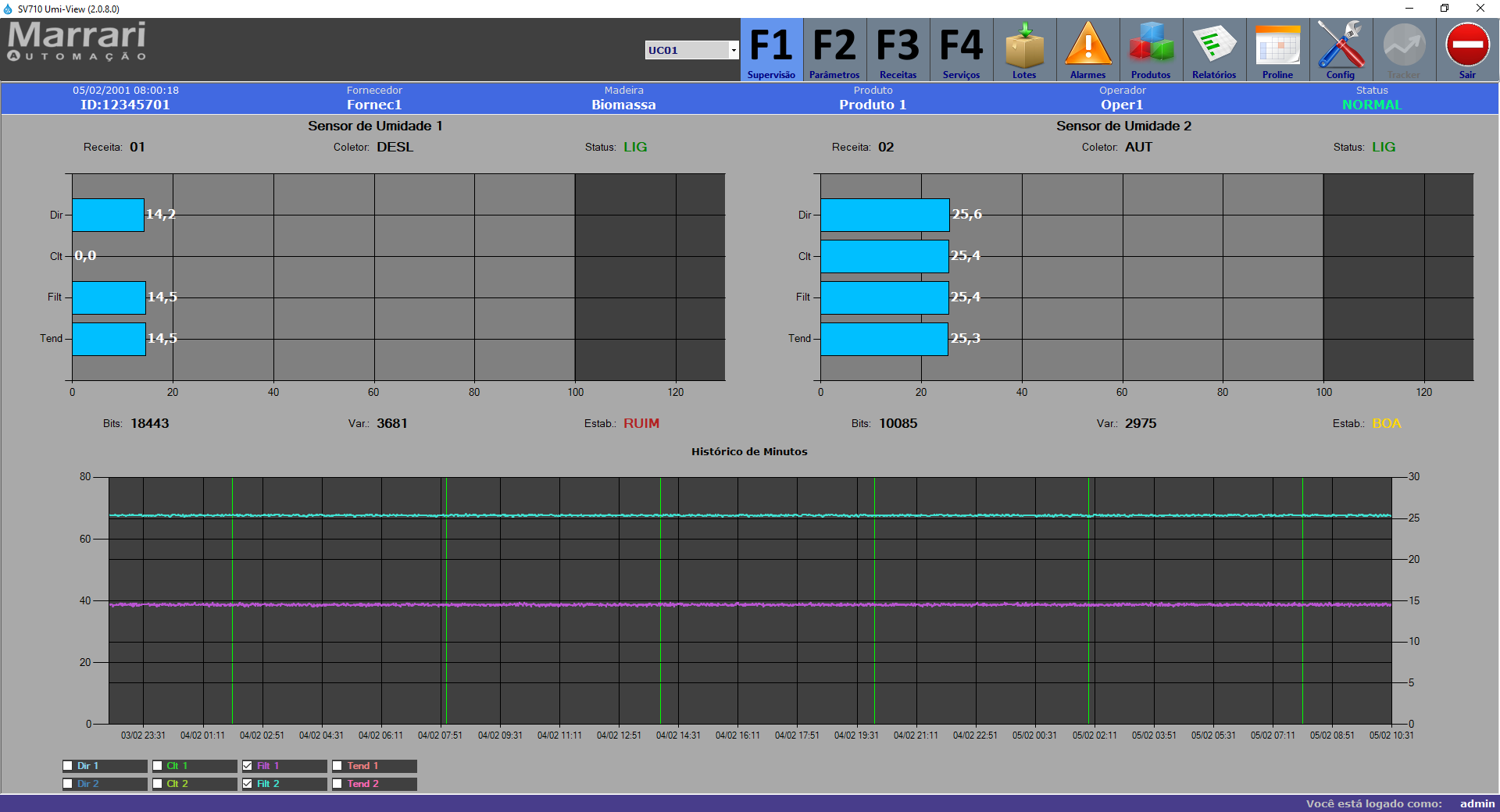

The UmiMate moisture meter is a Marrari solution for measuring the moisture content of yerba mate after it passes through the dryer. Readings are taken in real-time through a flat sensor that assesses the total volume produced.

WHY USE UmiMate IN MY PRODUCTION LINE?

Because measuring the moisture of your material/product is essential to maintain its quality. For example: if yerba mate leaves the oven with high moisture, it can lead to problems with the exothermic effect during storage, resulting in unnecessary product loss.

In addition to ensuring proper yerba storage, the UmiMate in-line moisture meter ensures that the final product’s taste quality is excellent due to the correct process management.

Benefits of measuring yerba mate moisture during its production process:

- Product Quality: Enables precise moisture control, ensuring consistent yerba mate quality.

- Production Consistency: Helps maintain consistency throughout the production process, avoiding unwanted variations.

- Operational Efficiency: Allows real-time adjustments in the process, optimizing operational efficiency.

- Loss Reduction: Prevents raw material and ingredient losses, contributing to more economical and sustainable production.

- Proper Storage: Influences the stability and durability of the final product, avoiding storage problems.

- Regulatory Compliance: Facilitates compliance with specific regulations related to moisture content in food products.

- Production Cost: Contributes to cost reduction, avoiding ingredient waste and ensuring efficient resource use.

- Consumer Health: Ensures that the final yerba mate meets quality standards, promoting consumer health and satisfaction.

- Food Safety: Helps prevent food safety issues related to excess moisture, which could lead to the growth of unwanted microorganisms.

- Market Differentiation: Allows you to stand out in the market by offering a high-quality and consistent product.

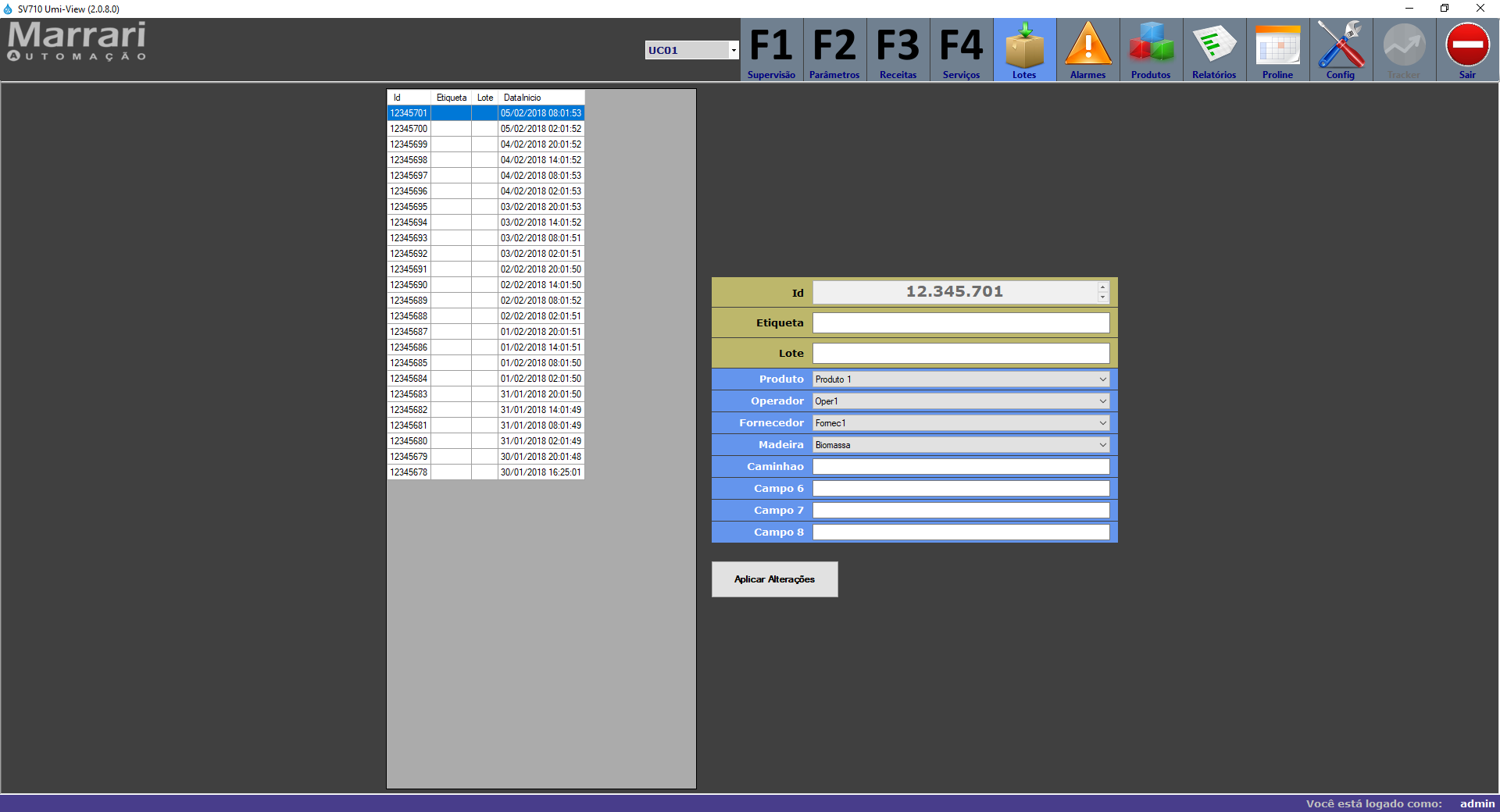

- Traceability: Facilitates the tracking of the production process, quickly identifying variations and enabling immediate corrective actions.

- Continuous Improvement: Provides valuable data for analysis and continuous improvement of production processes.

- Customer Satisfaction: Contributes to customer satisfaction by delivering a reliable and high-quality product.

In summary, real-time moisture measurement in yerba mate production is crucial to ensuring a high-quality final product, operational efficiency, and compliance with regulatory standards, resulting in significant benefits for the industry.

HOW DOES UmiMate WORK?

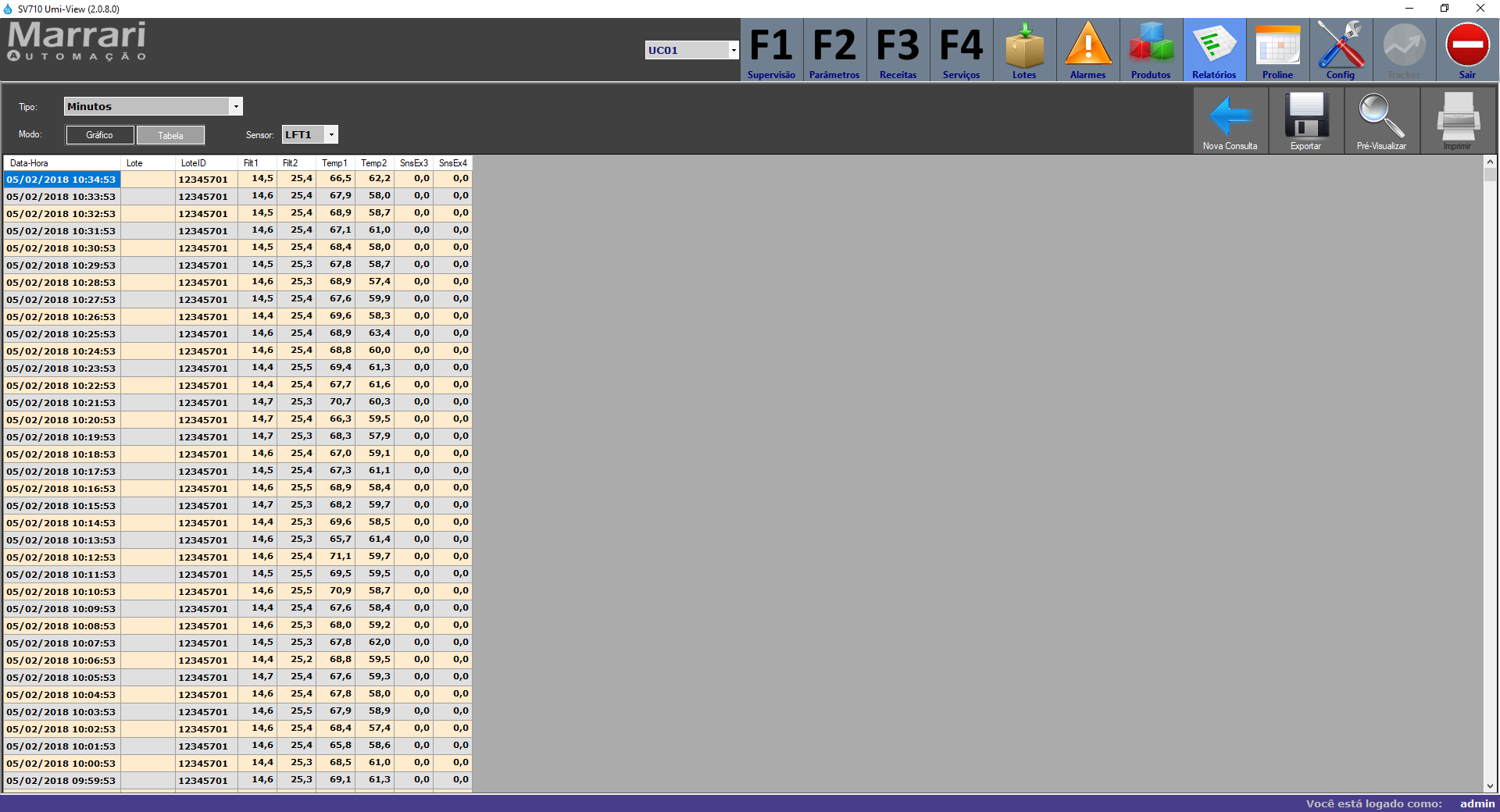

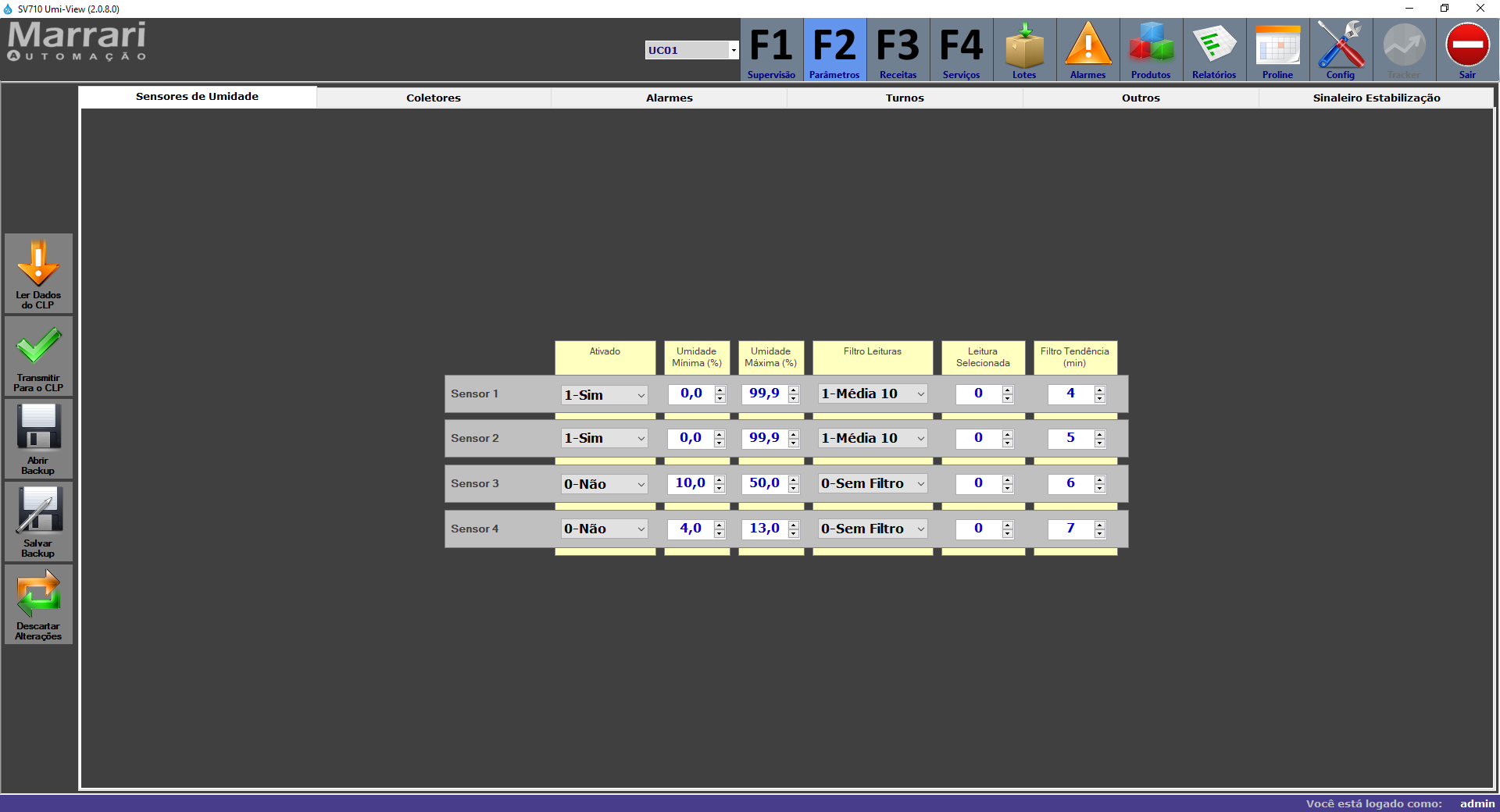

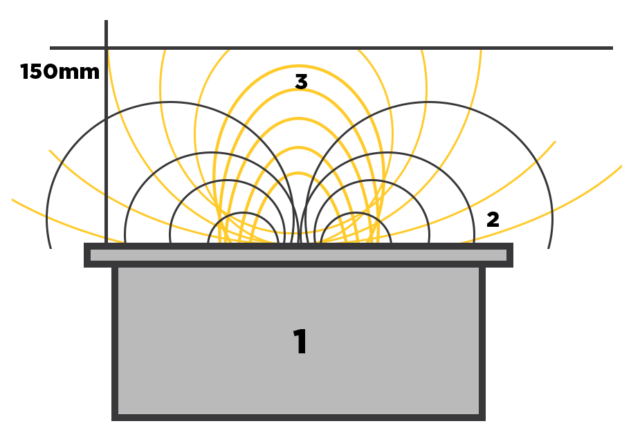

A capacitive sensor is installed at a strategic point in the process so that the material passes over the sensor. Moisture content readings are continuous, and the entire product that passes through the system is evaluated. The signal generated by UmiMate can be used to control the dryer or generate alarms that guide the system operator.

How does UmiMate manage to be SO ACCURATE?

It works using the capacitive method, that is, a sensor is installed on the conveyor belt and while the material is being carried along it, it passes over the sensor (1) and the moisture content of the product is read second by second in a height field of up to 150 mm (2 and 3). This provides a real measurement of the moisture content of the entire material, not just superficially.

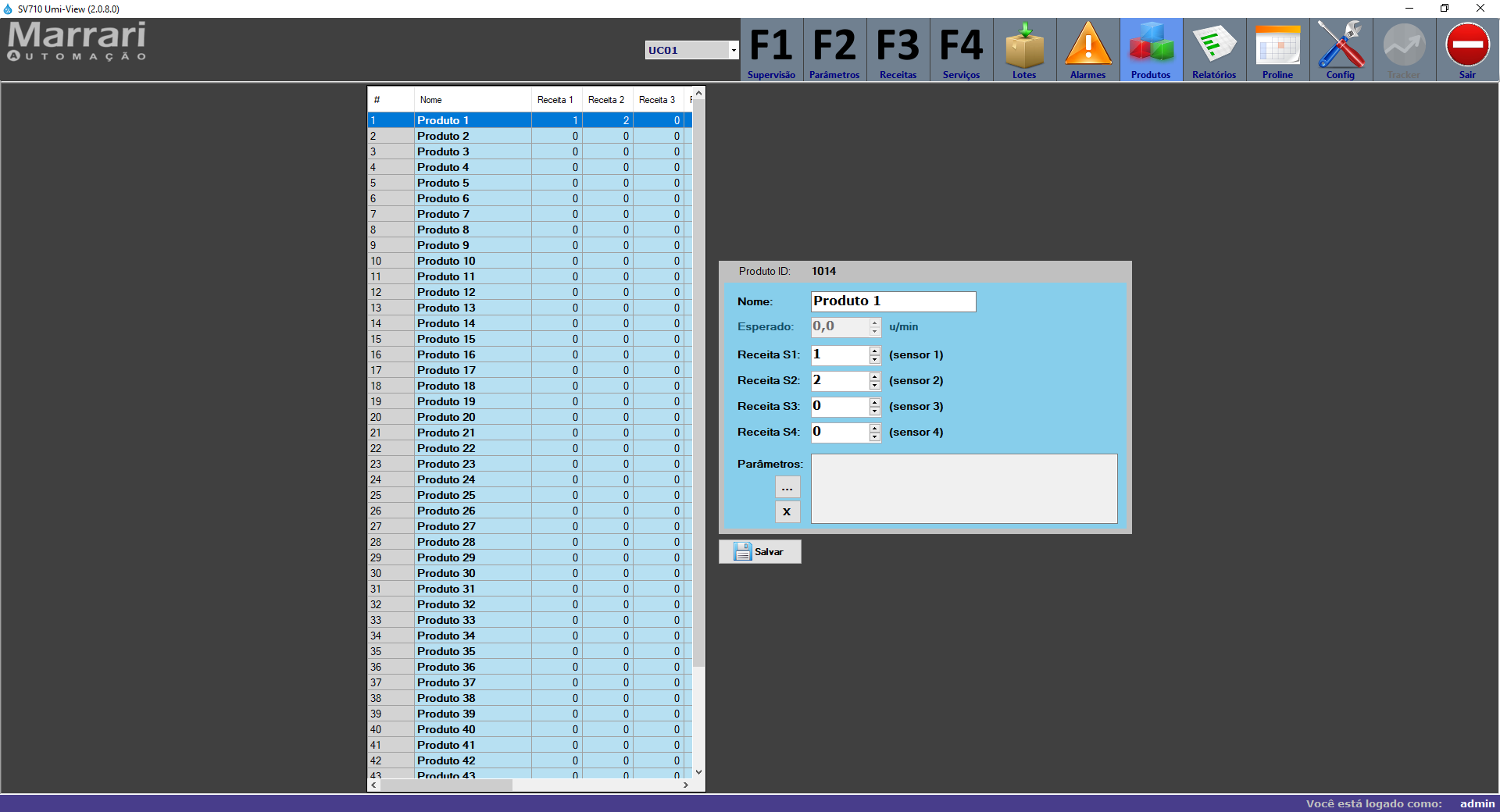

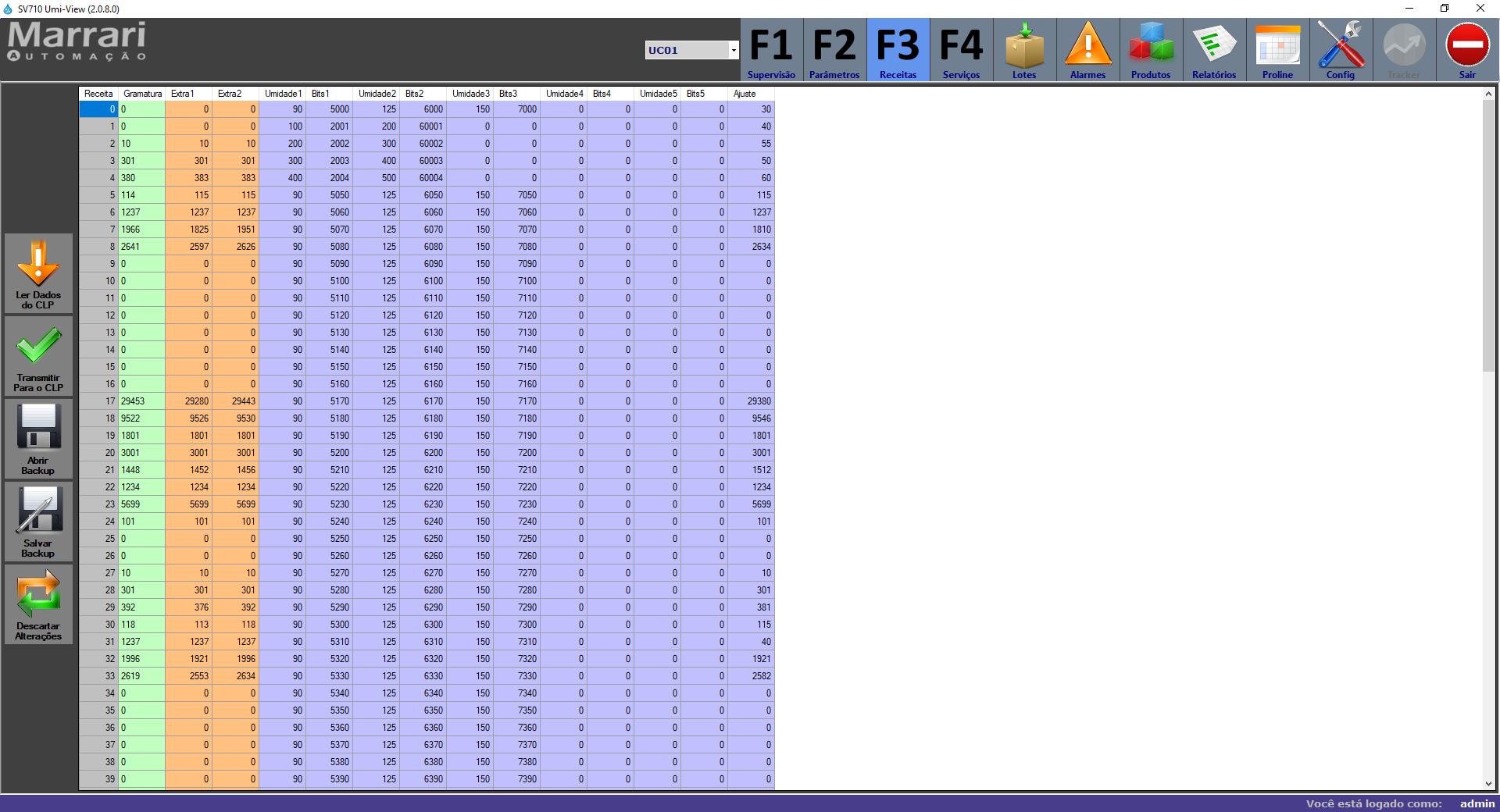

It also uses a recipe-based calibration method. In short: you use the Tracker (equipment that comes with the UmiChip) to collect samples throughout the day and compare them with the laboratory.

If there are discrepancies, you can go to the Tracker’s included software and update the values to match the laboratory assay, thus ensuring its accuracy.

IF I WANT TO BUY THE MOISTURE METER WITH A READY RECIPE FOR MY PRODUCT?

Just send a sample of your product to us at Marrari. Specifically, to Umilab, where we will create the calibration curve and recipe for you based on the laboratory assay!

Contact us to learn more!

AND WHY USE MARRARI EQUIPMENT?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss, using methods such as OEE and Industry 4.0. Thus, creating a more effective, productive, and modern production environment!

If you want to learn more about us and automation news, visit our blog, Facebook, or LinkedIn.

WARRANTY

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!