Grain Moisture Meter UmiGrain: Precision, Reliability, and Real-Time Results

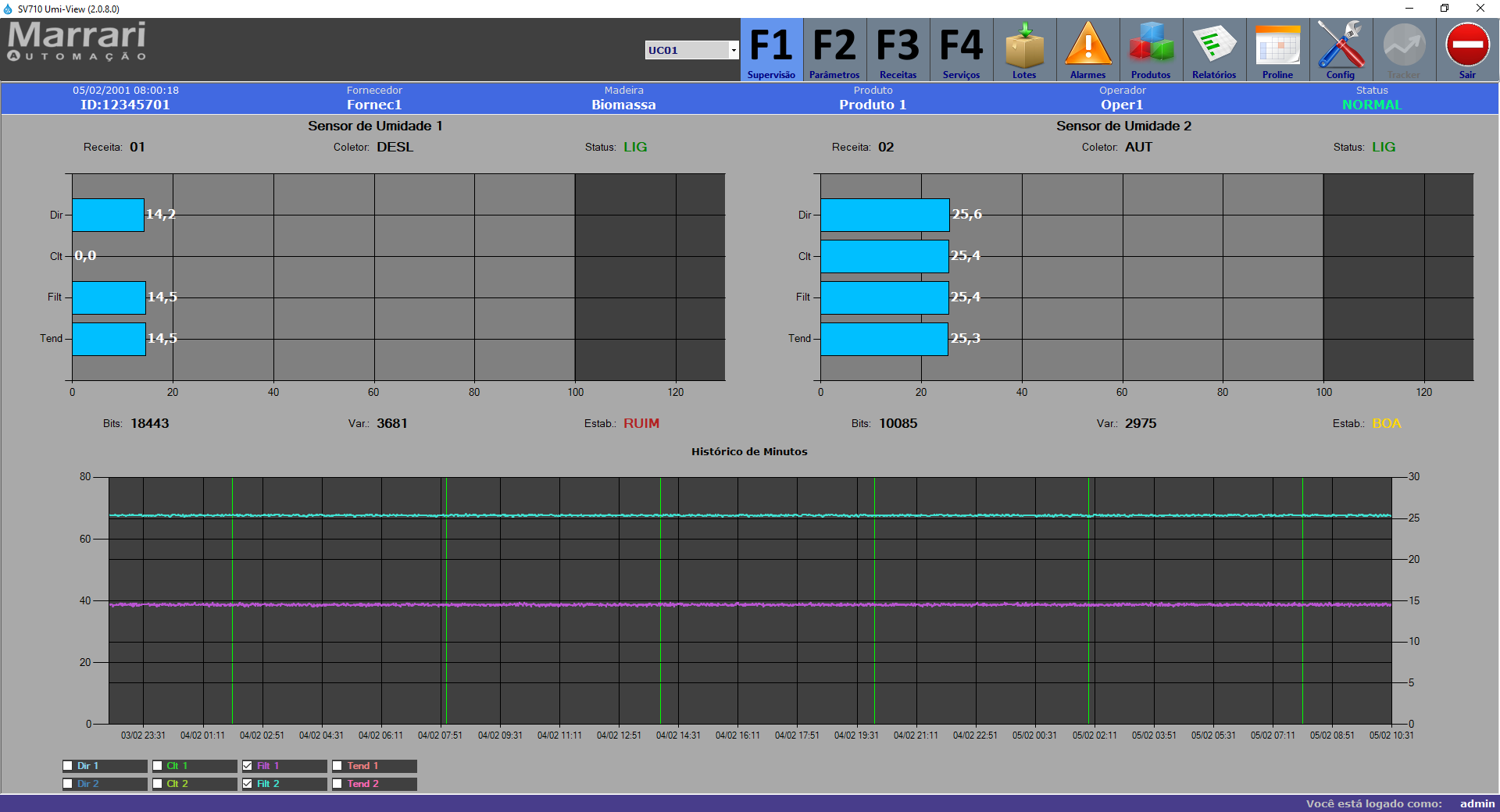

The UmiGrain grain and seed moisture meter by Marrari Automação is a high-tech solution designed to provide continuous, real-time measurements of moisture content in grains and seeds. Ideal for use before, during, and after the drying process, the UmiGrain employs robust sensors that analyze the dielectric stiffness of materials. This stiffness is directly correlated to both internal and surface moisture of the grains, enabling comprehensive and highly accurate measurements.

Why Use the UmiGrain Grain Moisture Meter?

Accurate control of grain moisture is a critical factor for maintaining quality, avoiding losses, and maximizing financial return. The UmiGrain moisture meter offers numerous advantages across drying, storage, and shipment processes:

-

Preserves grain and seed quality, preventing cracks that promote fungal growth and compromise product grading.

-

Prevents losses due to excessive moisture, which can lead to mold and bacterial growth, rendering large volumes of product unusable.

-

Avoids commercial penalties: Grains with moisture levels outside accepted standards are often devalued in the market.

-

Reduces losses from over-drying, which directly affects total mass. An unnecessary 1% moisture reduction in 100 tons can result in daily losses of up to 24 tons in a 24-hour plant.

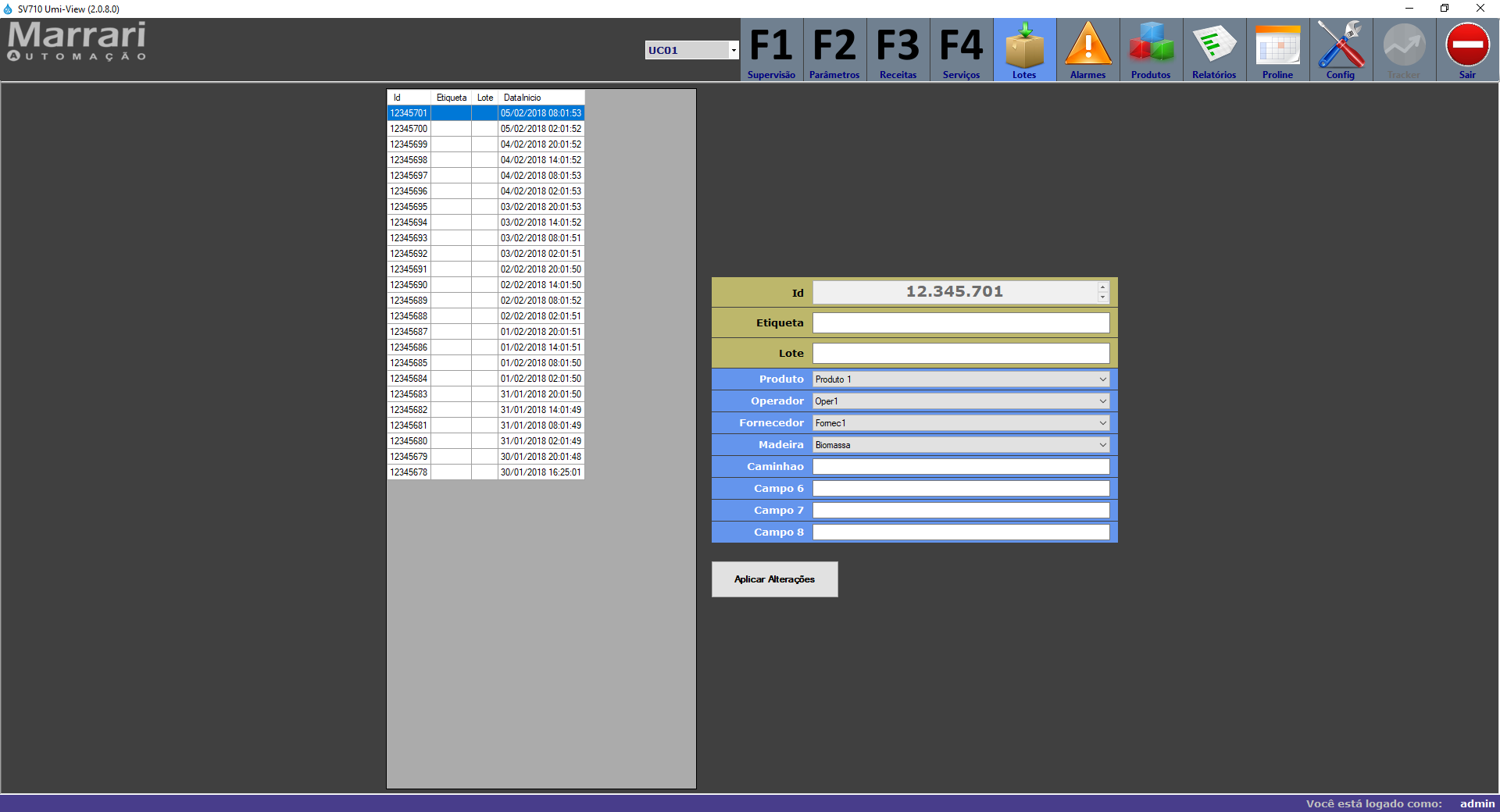

With UmiGrain, measurements are performed continuously and automatically, with the option for complete process registration and traceability. This reduces the need for frequent laboratory analyses, increases efficiency, and ensures documentation of final product quality.

Where Should the UmiGrain Grain Moisture Meter Be Installed?

Strategic installation of the UmiGrain moisture meter sensors is essential to ensure quality control and efficiency at every stage of the production process. Key application points include:

-

Grain reception: Identifies initial moisture content and supports decision-making regarding the need and intensity of drying.

-

Dryer outlet: Enables automatic adjustments to the drying process, preventing under or over-drying.

-

Transfer line to storage: Ensures moisture stability during internal transport.

-

Silo inlet: Confirms moisture content before storage, preventing losses during stockpiling.

-

Final shipment: Verifies that the grain meets required standards before delivery to customers.

How Does the UmiGrain Moisture Meter Work?

As the product passes through the measurement area, it enters an electric field generated by the sensor. The moisture present—both on the surface and inside—interferes with this field, and the variation is instantly interpreted by the sensor’s processor. The result is a highly accurate measurement, performed hundreds of times per second.

-

Conventional process: 2 samples/hour (0.5 kg/h)

-

UmiGrain: 18,000 readings/hour (180 kg/h)

That means UmiGrain delivers 360 times more data per hour than a conventional analysis, ensuring exceptional reliability.

Why Is UmiGrain So Accurate?

Its precision is the result of a combination of advanced features:

-

Cutting-edge physical measurement principle

-

High sensor stability

-

Fast data processing

-

Massive volume of readings per hour

-

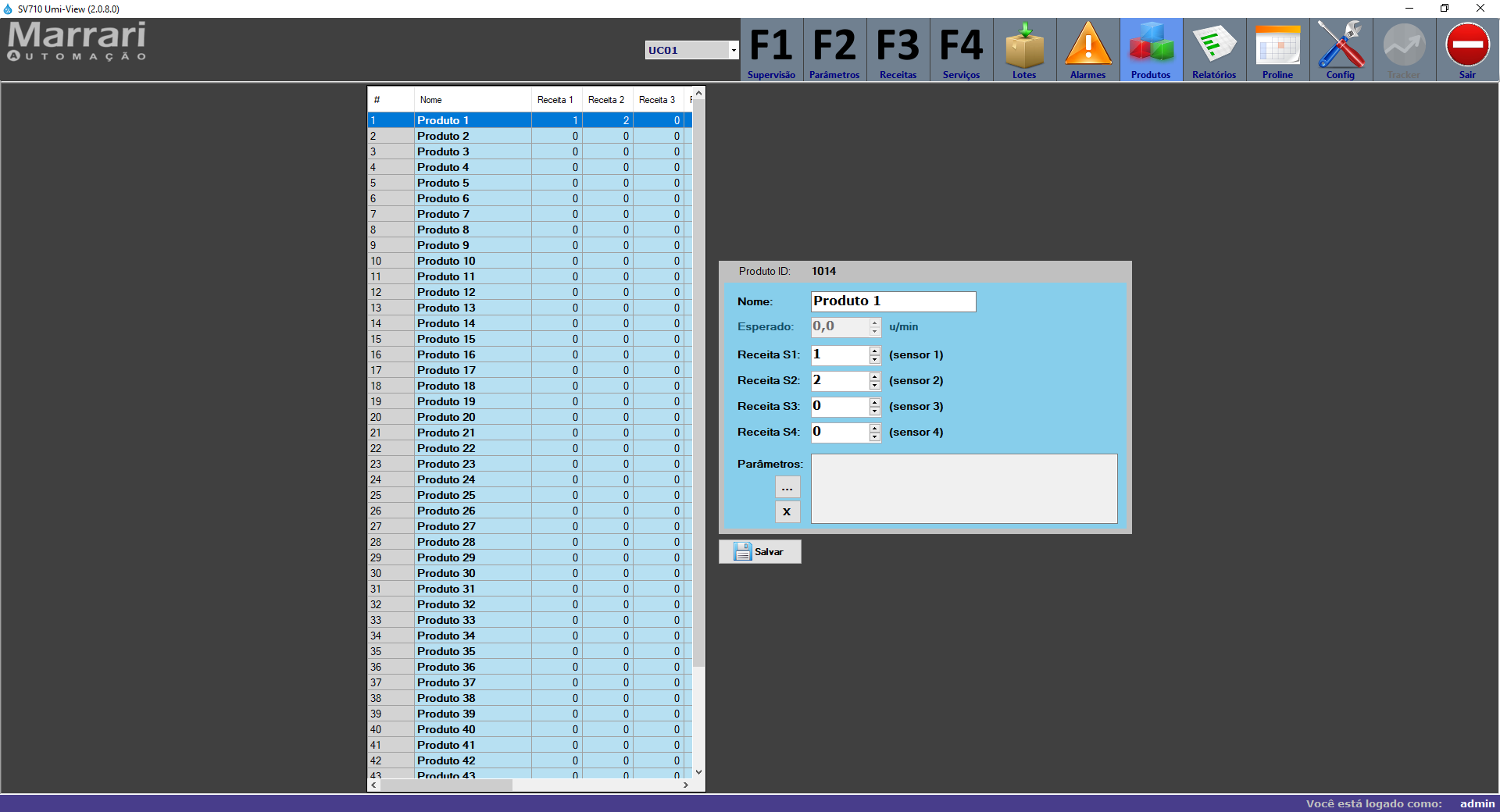

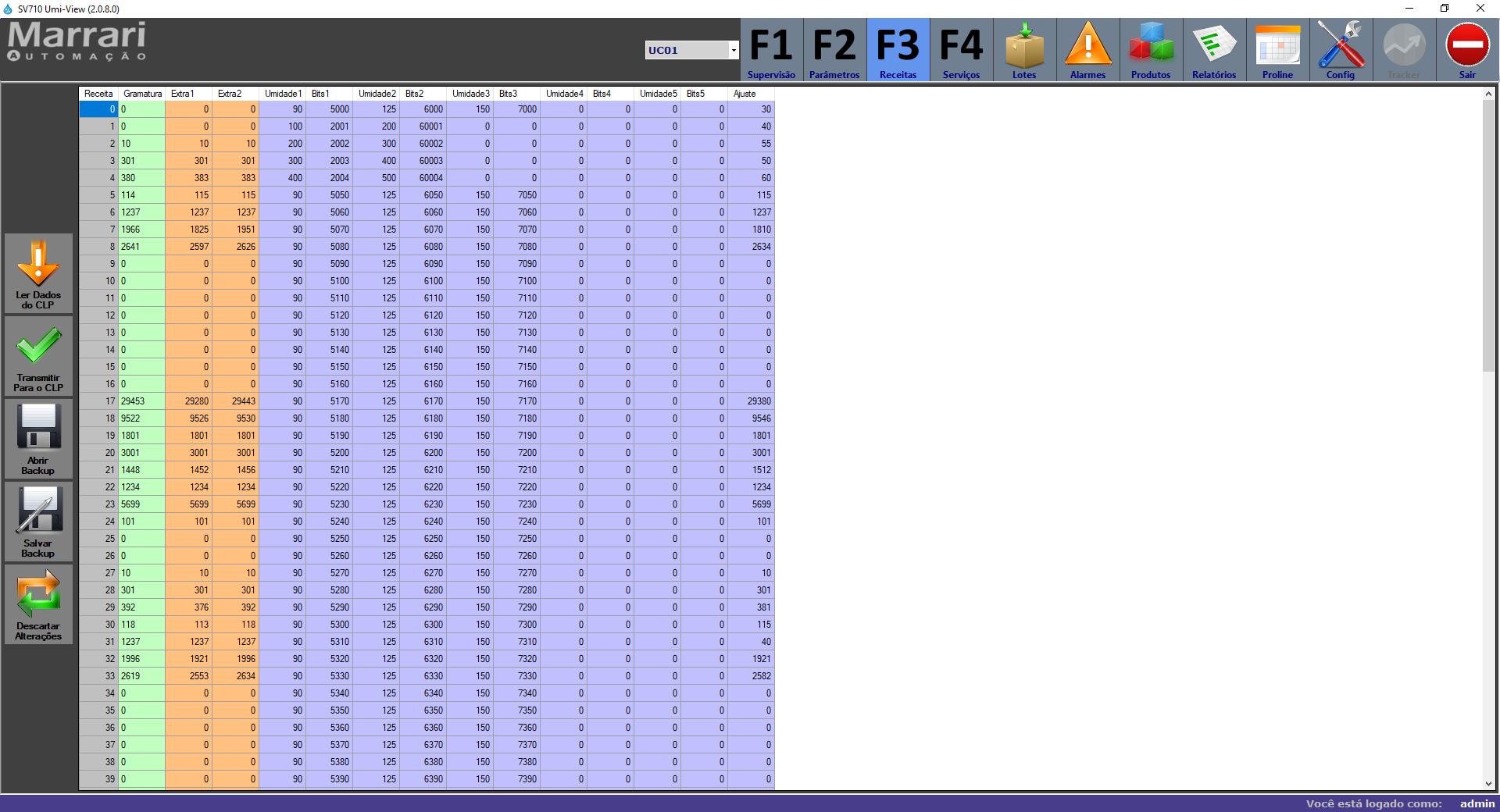

Product-specific calibration curves

-

Continuous improvement via the Tracker software

Is the UmiGrain Moisture Meter Pre-Calibrated?

Yes! UmiGrain is compatible with a wide variety of grains and seeds. It comes pre-calibrated for products such as:

-

Soybean

-

Rice

-

Beans

-

Sorghum

-

Barley

-

Wheat

-

Peanuts

-

And many more

If you require a specific calibration for your product, simply send a sample to Marrari’s Umilab laboratory. We’ll develop a personalized calibration curve based on the actual characteristics of your grain or seed.

What Are the Gains from Using the UmiGrain Moisture Meter?

The benefits of implementing UmiGrain are significant and measurable:

-

Reduces over-drying losses – Drying 1% more than necessary in a 100t/h process results in 1,000 kg/hour loss, or 24,000 kg/day.

-

Prevents spoilage losses – Ensures grains are not stored with excess moisture.

-

Avoids commercial discounts – For example, 4% excess moisture may lead to an 8% price reduction.

-

Speeds up drying with greater precision and control.

-

Remote operation via computer, smartphone, or PLC.

-

Analog and digital outputs, allowing easy integration with other plant systems.

What Are the Benefits of Measuring Moisture Post-Harvest?

The post-harvest phase is one of the most critical moments for preserving grain quality. Performing accurate and continuous moisture measurement immediately after harvest brings a series of strategic advantages to operations:

-

Enables quick and informed decisions regarding the necessity and urgency of drying, avoiding logistical delays and spoilage losses;

-

Reduces the risk of fermentation and microorganism proliferation, which are common when grains remain too moist for extended periods;

-

Ensures greater uniformity in moisture content during storage, preventing hotspots and minimizing the need for reprocessing;

-

Increases operational efficiency, by integrating moisture data into production management and planning for drying and storage logistics;

-

Preserves the commercial value of the grain, avoiding downgrades due to off-spec moisture levels at the very start of the supply chain.

By incorporating post-harvest moisture monitoring with UmiGrain, producers and industries ensure immediate response to product conditions, reduce risks, and enhance quality control from the very first stage after harvest.

How does UmiGrain manage to be SO ACCURATE?

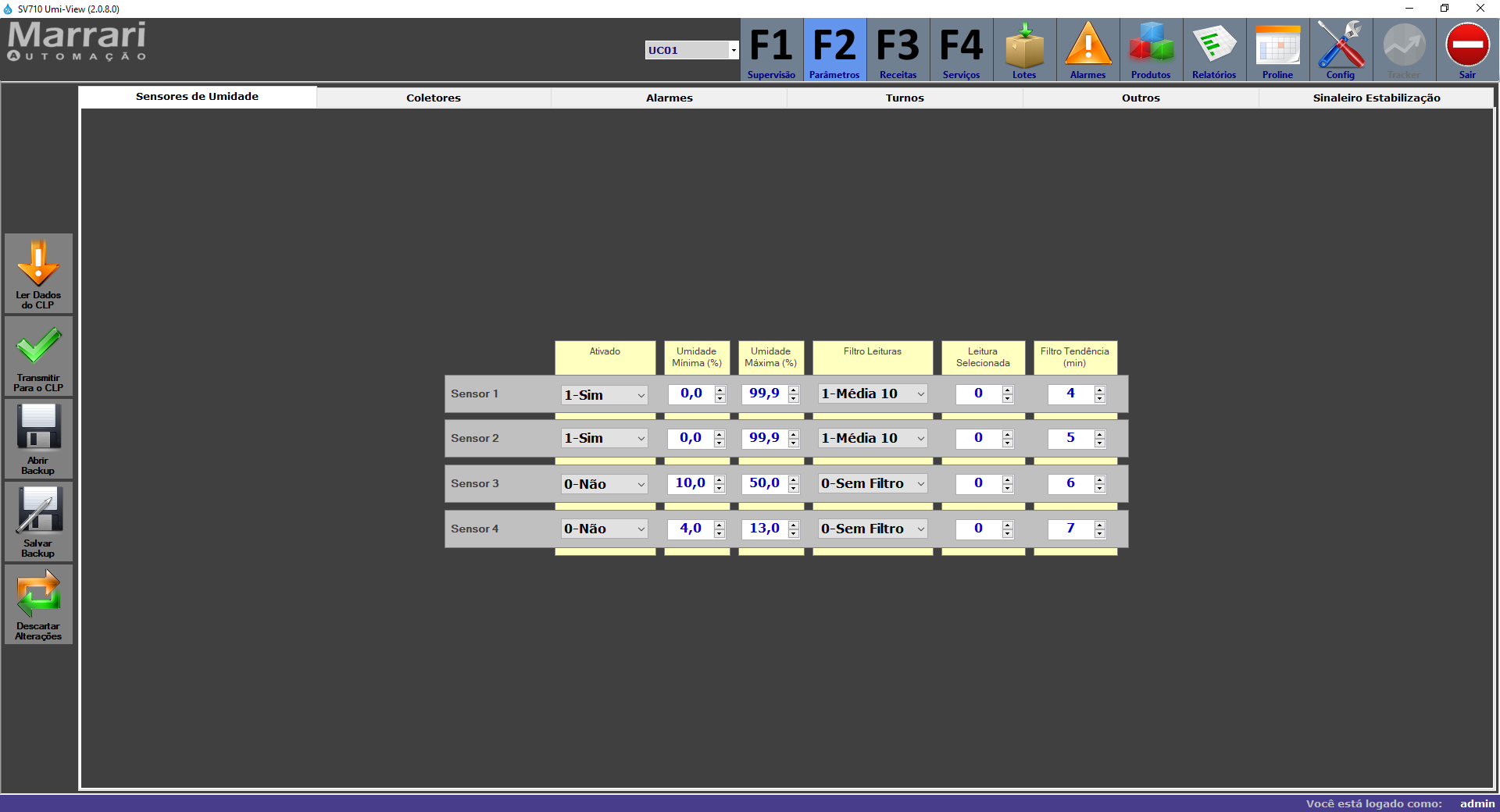

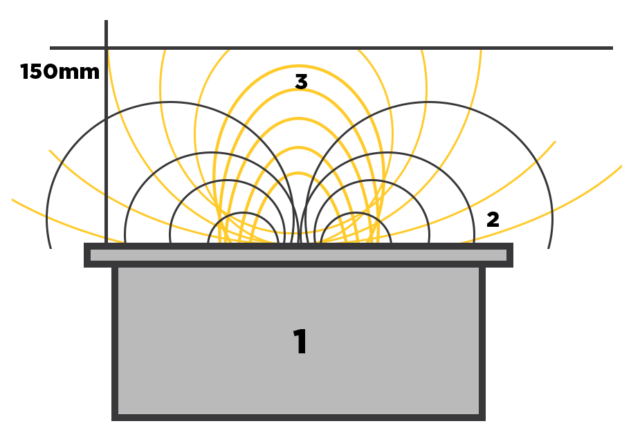

O sensor funciona pelo método capacitivo, ou seja, é instalado um sensor na esteira, transportador, secador, ou outro local e enquanto o grão é carregado pela mesma, ele passa pelo sensor (1) e é lido a umidade do produto segundo a segundo em um campo de altura de até 150mm (2 e 3). Assim tendo uma medição real da umidade de todo o material, não apenas superficialmente.

Trusted and Recommended

Dozens of UmiGrain systems are already in operation throughout Brazil and Latin America, serving agribusiness companies that seek efficiency, accuracy, and full control over the quality of their grains.

AND WHY USE MARRARI EQUIPMENT?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss, using methods such as OEE and Industry 4.0. Thus, creating a more effective, productive, and modern production environment!

If you want to learn more about us and automation news, visit our blog, Facebook, or LinkedIn.

WARRANTY

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!