What is KD & HT phytosanitary control?

KD & HT phytosanitary control is a technique used to treat wood and eliminate living organisms that can cause damage to wood and human health. Kiln-Drying (KD) is a wood drying process in a kiln that uses high temperatures to kill insects and other living organisms that may be present in the wood. Heat Treatment (HT) is a thermal treatment process that uses even higher temperatures to kill organisms that may be present in the wood.

There are several reasons why KD & HT phytosanitary control is important for the wood industry. Firstly, it helps protect wood against pests and diseases that can weaken the wood structure and reduce its lifespan. This is especially important for woods that will be used in humid environments or exposed to weather conditions, where the presence of living organisms can accelerate wood deterioration.

Moreover, it is crucial from a public health perspective. Some insect species and other organisms present in wood can carry diseases that can be transmitted to humans. By treating wood with KD & HT phytosanitary control, it is possible to eliminate these organisms and reduce the risk of disease transmission.

Finally, it is essential for the wood industry because many countries have strict regulations regarding the import and export of wood. These regulations often require wood to be treated to eliminate living organisms before being exported to other countries. Using KD & HT phytosanitary control can help ensure compliance with these regulations and avoid legal and commercial issues.

And why use Marrari’s phytosanitary control?

Because the Ministry of Agriculture, Livestock, and Supply (MAPA, this is for Brazil, other countries have other governamental regulators) requires phytosanitary certification, signed by an agronomist, to authorize the export of wood from Brazil to other countries.

Another reason MAPA (this is for Brazil, other countries have other governamental regulators) requires the use of phytosanitary control is to prevent the spread of pests and diseases among plantations and forests in the country. These pests and diseases can be transported through wood, leading to the spread of diseases and the death of trees and plants in other regions of the country.

In terms of the wood industry for export, MAPA (MAPA, this is for Brazil, other countries have other governamental regulators) requires the use of phytosanitary control and certification to ensure that wood exported by Brazil meets international phytosanitary safety standards. Many countries have strict regulations regarding wood importation and require wood to be treated to eliminate pests and diseases before importation. Using phytosanitary control can help ensure compliance with these regulations and avoid legal and commercial issues.

How does phytosanitary control work?

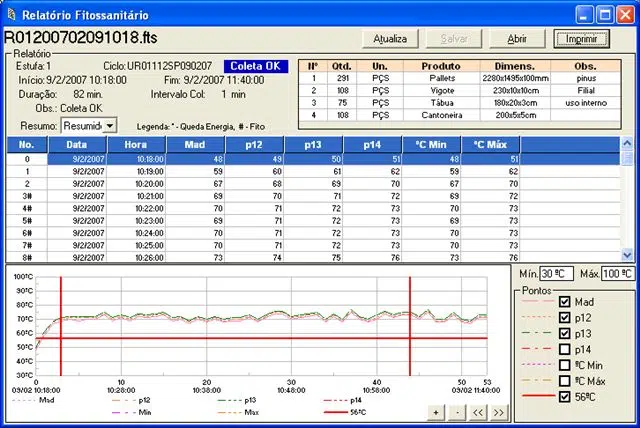

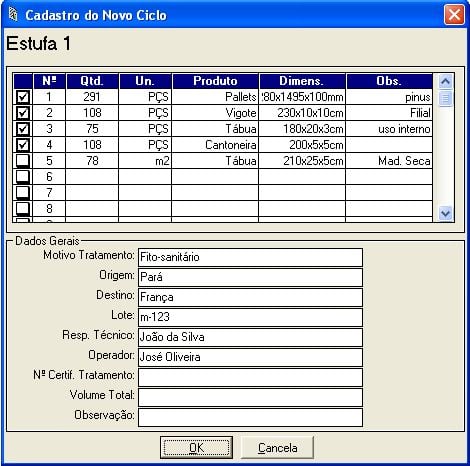

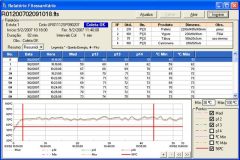

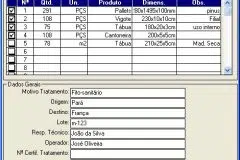

The KD & HT phytosanitary control system for wood is a process that monitors drying inside the kiln and thermal treatment to eliminate pests and diseases present in the wood. Drying is done in a kiln with controlled temperature and humidity, monitored by the Marrari controller, and thermal treatment is carried out in a treatment chamber or during drying, where the wood is heated to a temperature determined by the wood buyer country for a specified period.

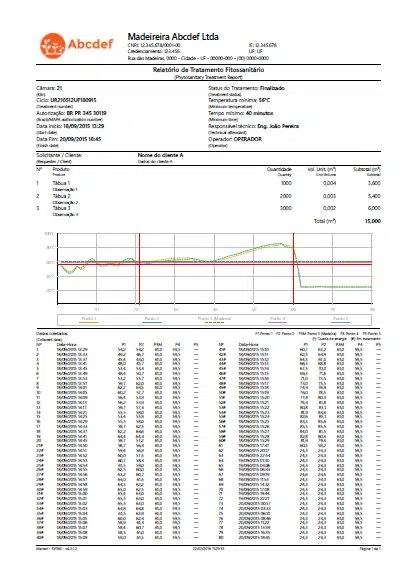

After this treatment, the system issues a certificate that must be authenticated and signed by an agronomist to release the wood for export.

The KD & HT phytosanitary control process is a more sustainable and environmentally friendly technique, as it does not use chemicals that can be toxic and polluting. It is an alternative to traditional methods of pest and disease elimination in wood and is required by national and international standards and regulations for the export of wood products.

Does Marrari perform phytosanitary treatment?

No, Marrari only offers the system that monitors and records all stages of the treatment process, generating a comprehensive report in which an agronomist can attest that the wood has completed all treatment requirements and is ready for export. This document is also approved and easily understood by MAPA (this is for Brazil, other countries have other governamental regulators).

AND WHY USE MARRARI EQUIPMENT?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss using methods like OEE and Industry 4.0. Thus creating a more effective, productive, and modern production environment!

If you want to know more about us and automation news, visit our blog, Facebook, or LinkedIn.

WARRANTY

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!