What is the M55-56 Sword wood moisture meter?

The M55-56 Sword wood moisture meter is a moisture meter for wood that features a 110cm measuring probe for insertion into the middle of pallets or panels. Its robust construction, using high-quality materials, allows it to be used on the factory floor, at the entrance and/or exit of the drying kiln, among other locations.

This moisture determiner is used on the factory floor and at the entrance and/or exit of the drying kiln, so its construction is robust, using high-quality materials to withstand daily use.

And what is the significant difference between the M55-56 Sword wood moisture meter and the M51 and M52 meters?

The M55-56 Sword has a 110cm probe for insertion into the middle of wooden pallets or panels, encompassing more than one wood plank in the measurement, resulting in a much more accurate average.

In addition to this moisture measurement probe, it also has another measurement point on the meter itself, just like an M51 or M52.

For you, as a manager or production leader, what does the M55-56 Sword wood moisture meter offer?

It comes with our software, UmiData, a powerful tool for storing data collected by the meter and downloaded via USB to a PC.

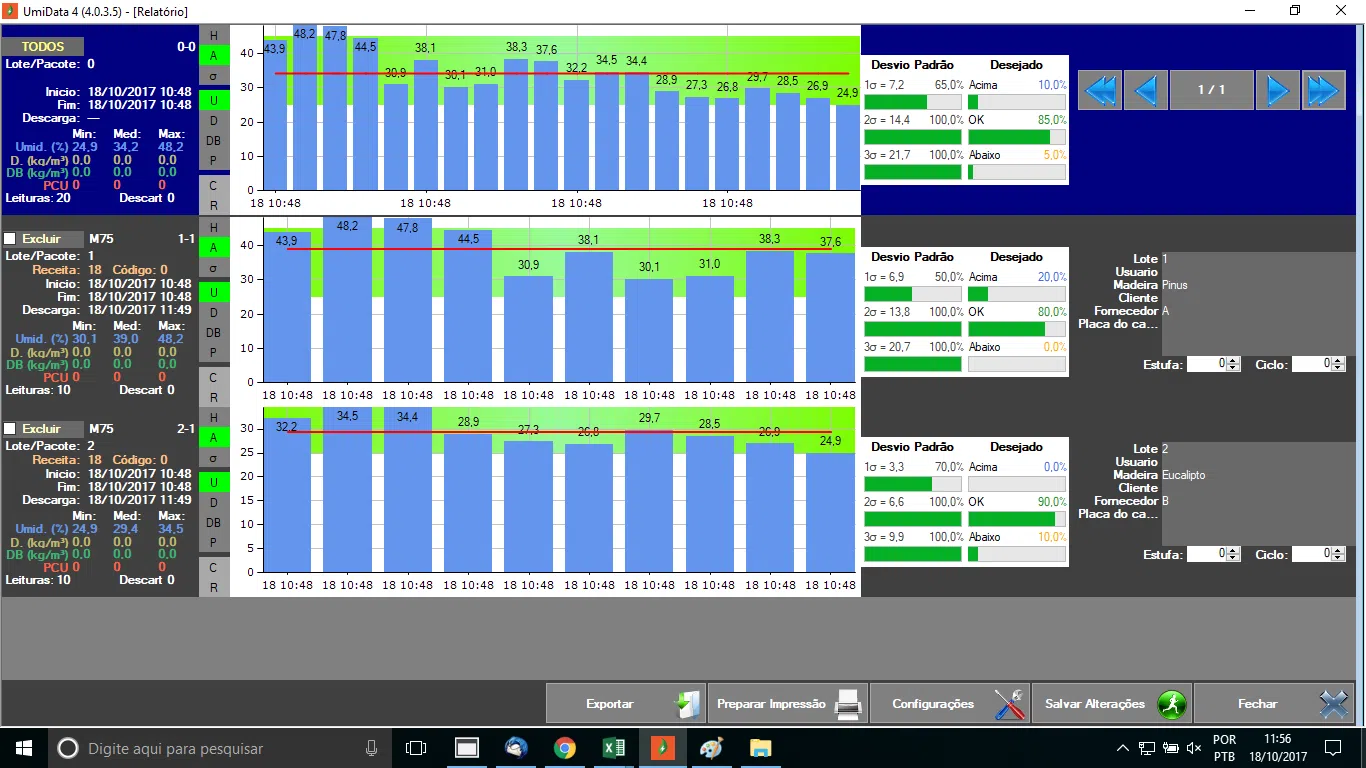

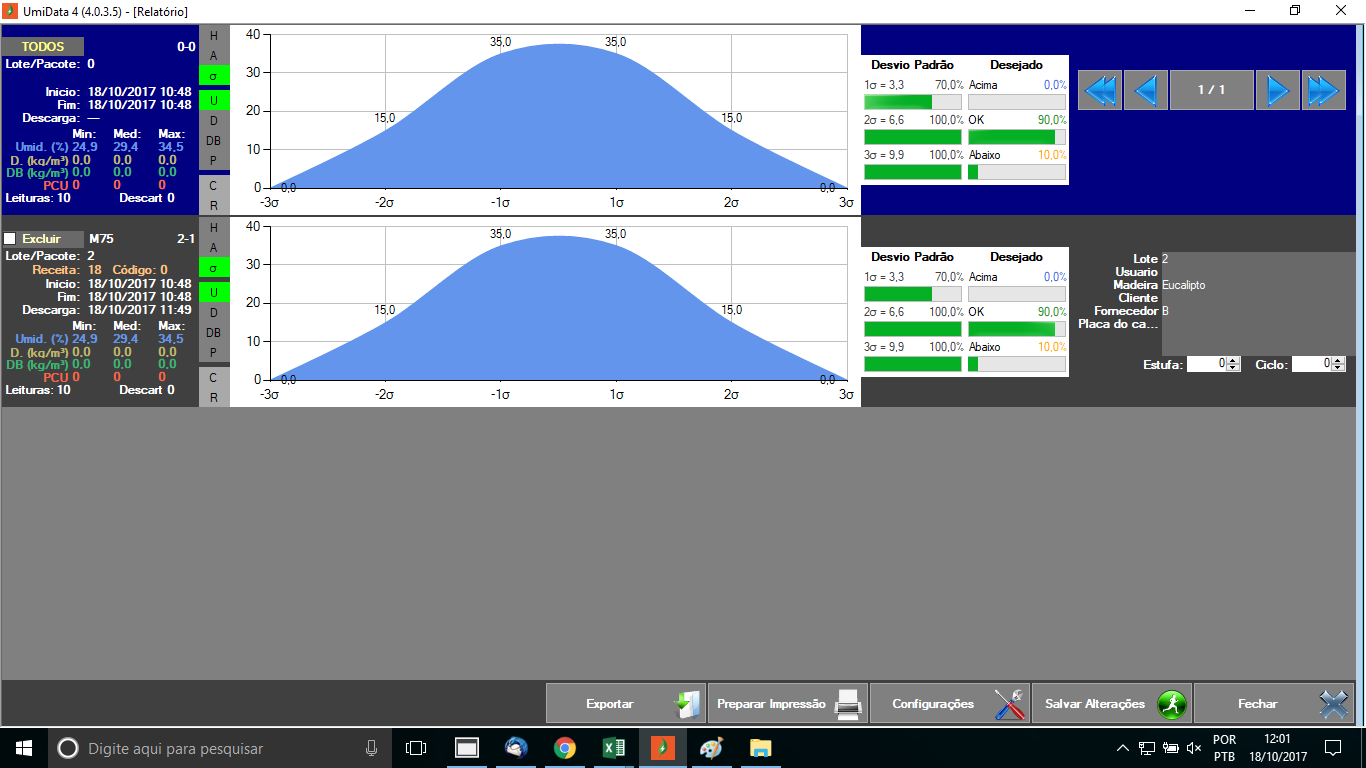

These data can then be displayed in various types of graphs, histories, and exported in Excel or other file formats.

What is the UmiData software?

UmiData is a powerful tool for data collection and storage. Through this supervisory tool, it’s possible to create and analyze recipes present in the equipment.

The collected data (moisture readings) can be downloaded via USB cable to a PC to be displayed through reports, graphs, histories, and tables. In addition to the online viewing of these reports, there is also the option to export them in CSV format to be read via Excel, ensuring better optimization for your company!

Why have a wood moisture meter?

It is important to have a moisture meter like the M55-56 Sword in the wood drying process because wood quality can be determined by moisture. Excessively moist wood can develop mold, i.e., create fungi, and overly dry wood can warp and become unusable.

Find out more about why and how measuring wood moisture can improve your process by clicking here.

Benefits of having an M55-56 Sword:

- Quality control of the process

- Better wood utilization (avoids waste)

- More data for decision-making in the sawmill or drying process

- Production management of wood drying

- Moisture reports and histories

- Better ability to predict or identify errors in the process

- Ability to measure more than one plank at a time, thus obtaining a more accurate average of moisture

And how do I know if my meter is accurate?

Marrari offers a calibration service with UmiLab, where you send your meter to us, and we conduct all necessary tests and calibrations to ensure that your equipment is functioning and measuring with 100% accuracy.

On the UmiLab page, you can request a quote for this calibration or for other equipment.

And why use Marrari equipment?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss using methods like OEE and Industry 4.0. This creates a more effective, productive, and modern production environment!

If you want to know more about us and automation news, visit our blog, Facebook, or LinkedIn.

GUARANTEE

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!