What is the Log X log classifier?

The Log X log classifier for sawmills is the complete solution for separating or classifying logs at the sawmill entrance. Logs are sorted by their diameter and/or length, maximizing the utilization of wood.

Why classify logs by class?

Depending on the type of final product, the operator can choose the ideal log class to maximize production, avoiding wood losses and unnecessary cuts.

Benefits of Log Classification:

- Efficiency in Production:

- Classification allows grouping logs with similar characteristics, optimizing resource usage and increasing production process efficiency.

- Quality of the Final Product:

- By classifying logs based on features such as size, density, and wood quality, it ensures that the final product meets desired quality standards.

- Optimization of Raw Material Use:

- Classification helps use raw materials more efficiently, minimizing waste and maximizing wood utilization according to its properties.

- Process Control:

- Classification facilitates industrial process control, allowing precise adjustments and maintaining consistent standards throughout production.

- Cost Reduction:

- By optimizing wood usage and improving efficiency, classification contributes to operational cost reduction.

- Prevention of Future Problems:

- Identifying specific log characteristics during classification helps predict and avoid problems that may arise during processing, ensuring smoother production.

- Meeting Market-Specific Requirements:

- Classification enables the production of different product categories that meet specific market requirements, allowing greater diversification of offerings.

- Improvement in Safety:

- Dealing with classified logs makes processes more controlled, contributing to a safer working environment.

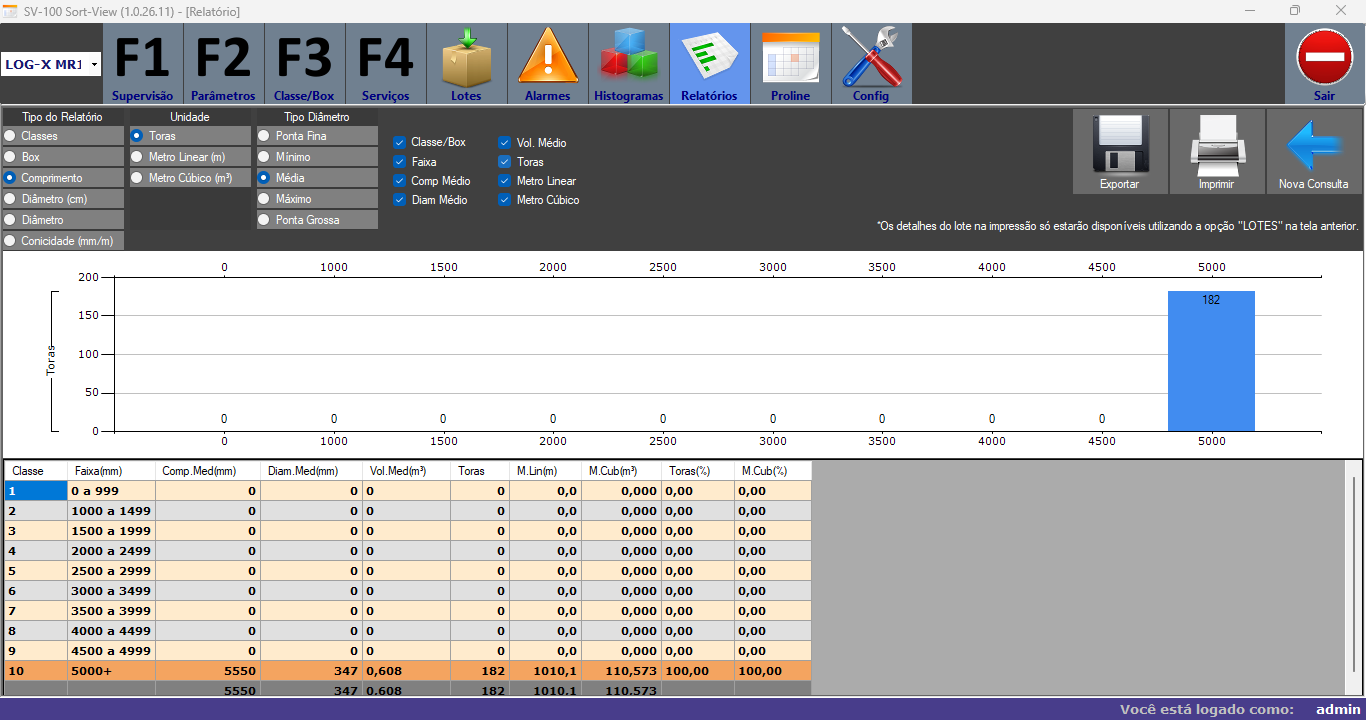

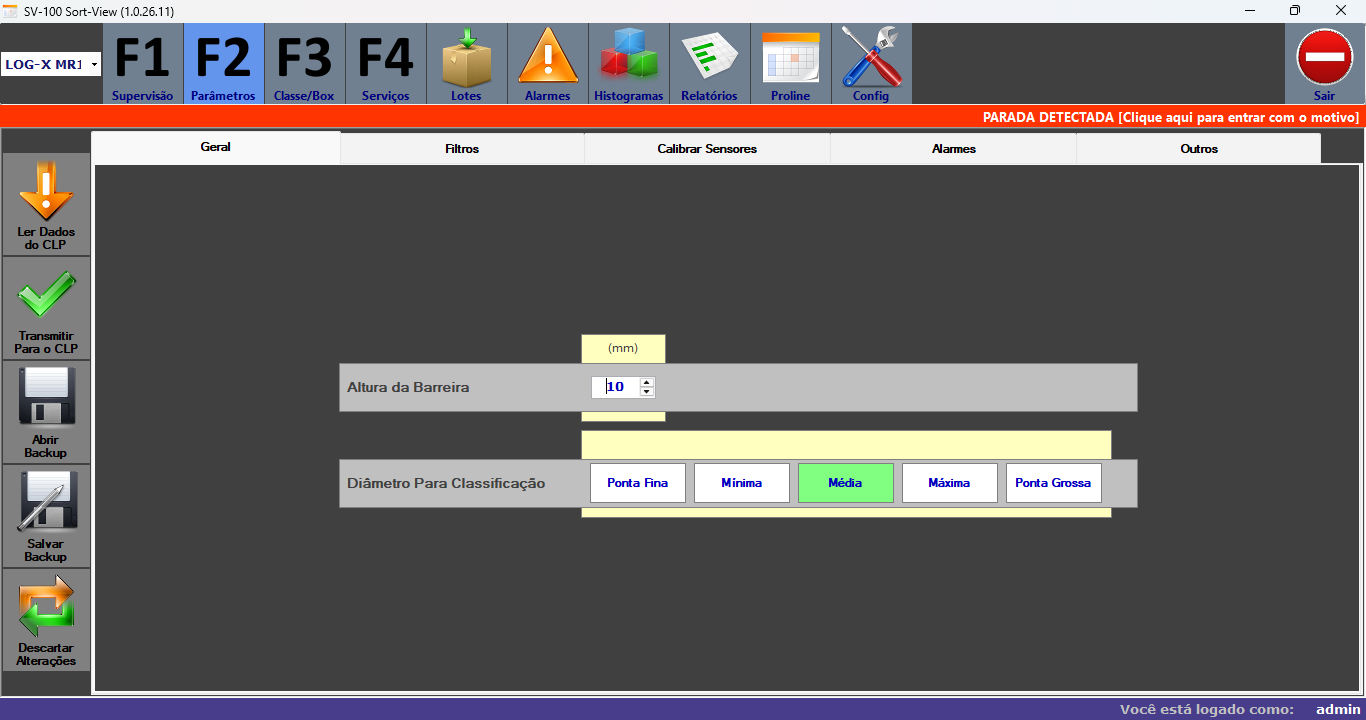

How to monitor the log CLASSIFIER?

Supervision and control software accompany the LOG-X, providing the operator with all the necessary process information: changes in classification parameters, volume of received logs, volume of logs in each class, and a dozen other pieces of information that allow for proper remuneration of suppliers, classification based on the type of material they provide, production scheduling based on available logs, and a variety of other possibilities.

And why use Marrari equipment?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive losses, using methods such as OEE and Industry 4.0. This creates a more effective, productive, and modern production environment.

If you want to learn more about us and stay updated on automation news, visit our blog, Facebook, or LinkedIn.

WARRANTY

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!