What is the SCADA – PSi4 supervisory system?

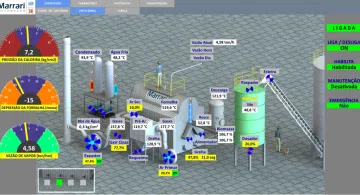

The PSi4 System is an industrial SCADA supervisory system developed based on the concepts of Industry 4.0. Its purpose is to offer a tool for monitoring and supervision of multiple processes, allowing for integrated management and control of industrial plants (in any sector), building automation, various brands of hospital automation, PLCs, as well as all Marrari systems.

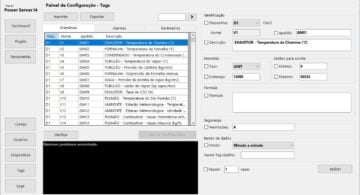

The system is fully configurable by the user or integrator, providing a powerful tool for real-time process supervision and management.

The PSi4 System (industrial SCADA and industrial control supervisory system) is a package composed of several software components:

Si4 Server – Data and Services Platform

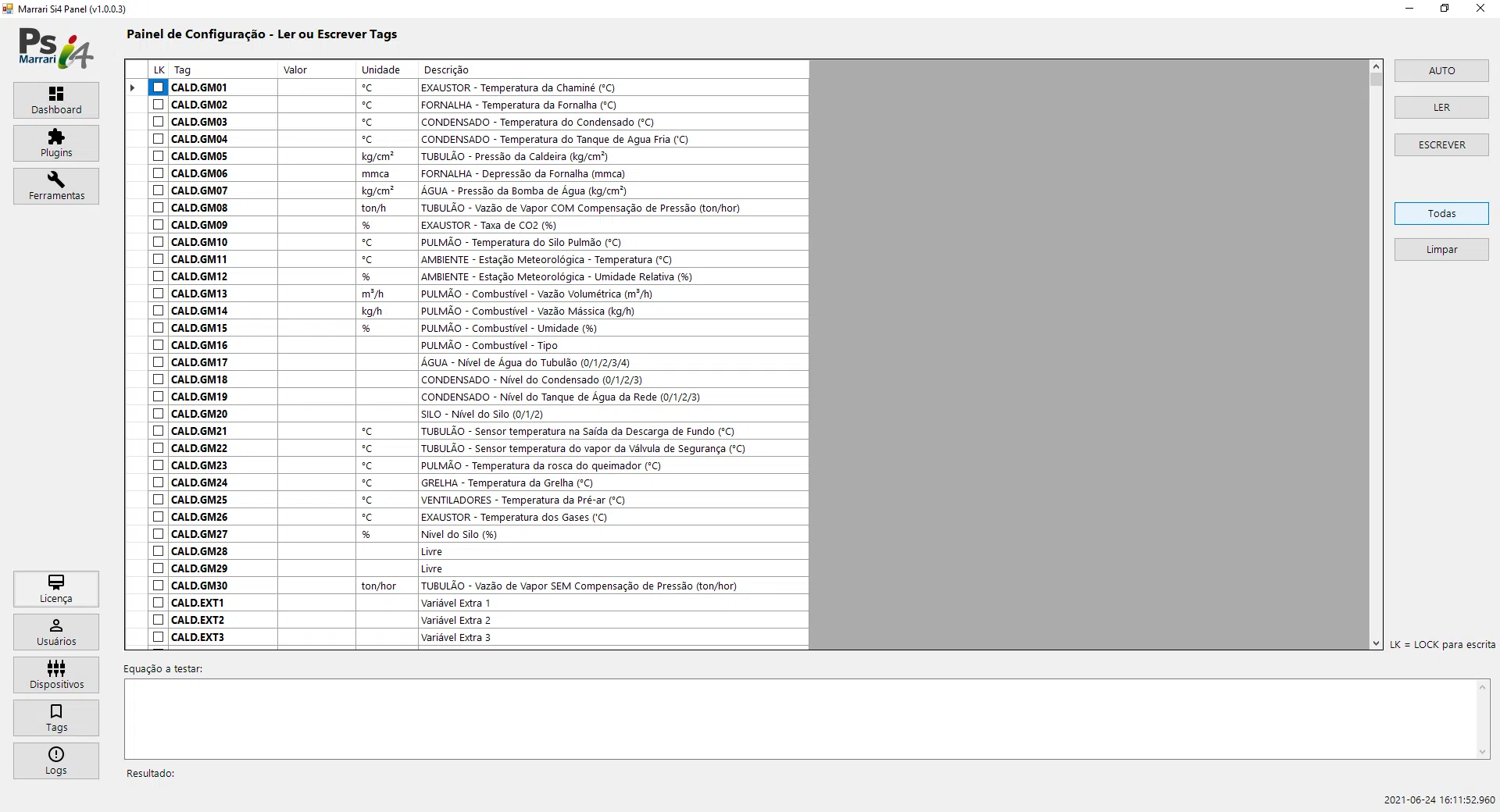

The Si4 Server (within this industrial control SCADA system) is responsible for acquiring and storing data from plant devices, making this information available to the entire platform environment and for external integration. It includes tools for monitoring and maintaining the device network and collected data. Other software components can visualize and act in real-time on the plant’s activities using the Si4 Server, as well as query the collected data history for various studies. All resources of the Si4 Server have multi-user access control for system security.

Vi4 Viewer – Supervision Platform

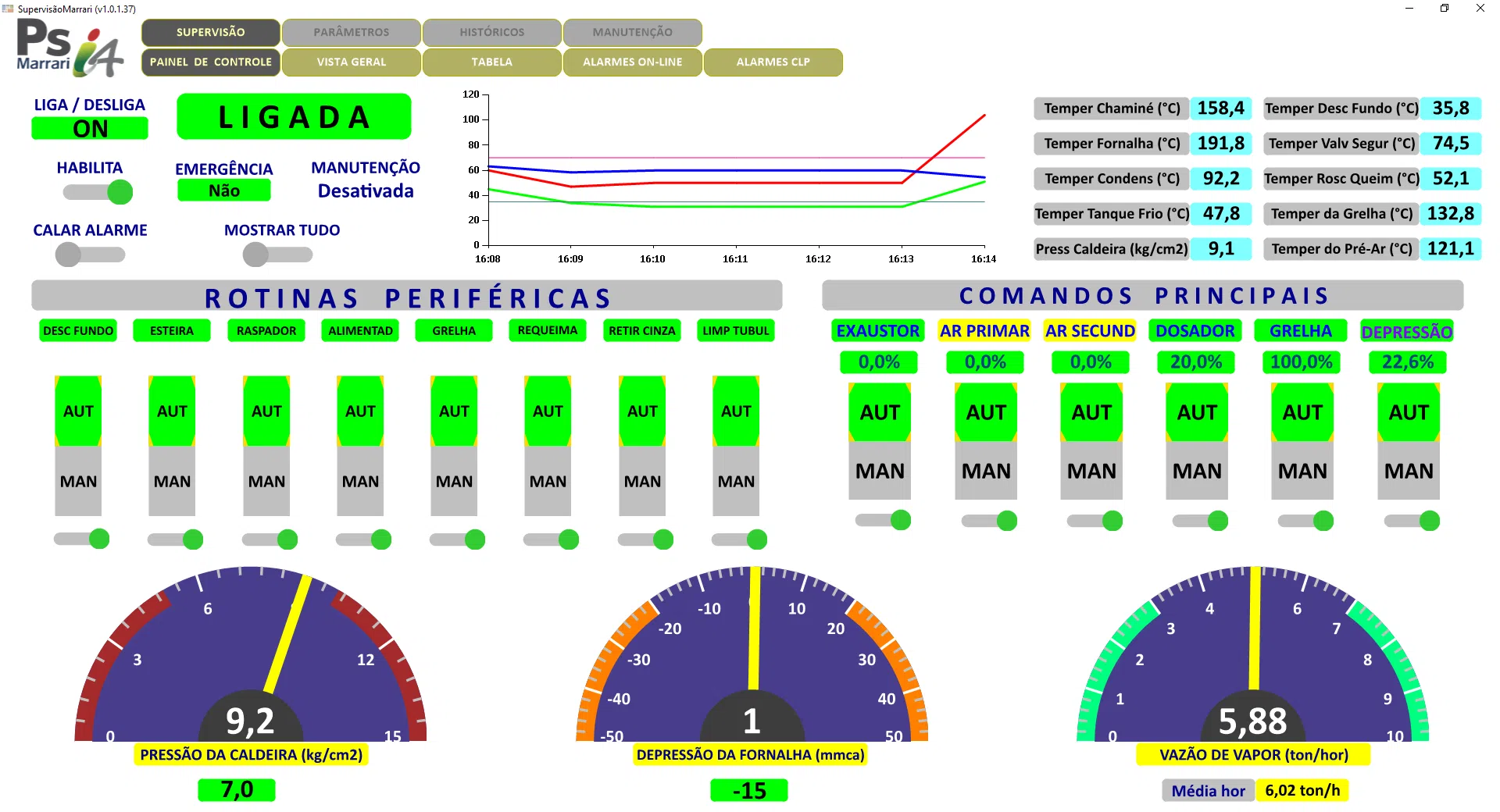

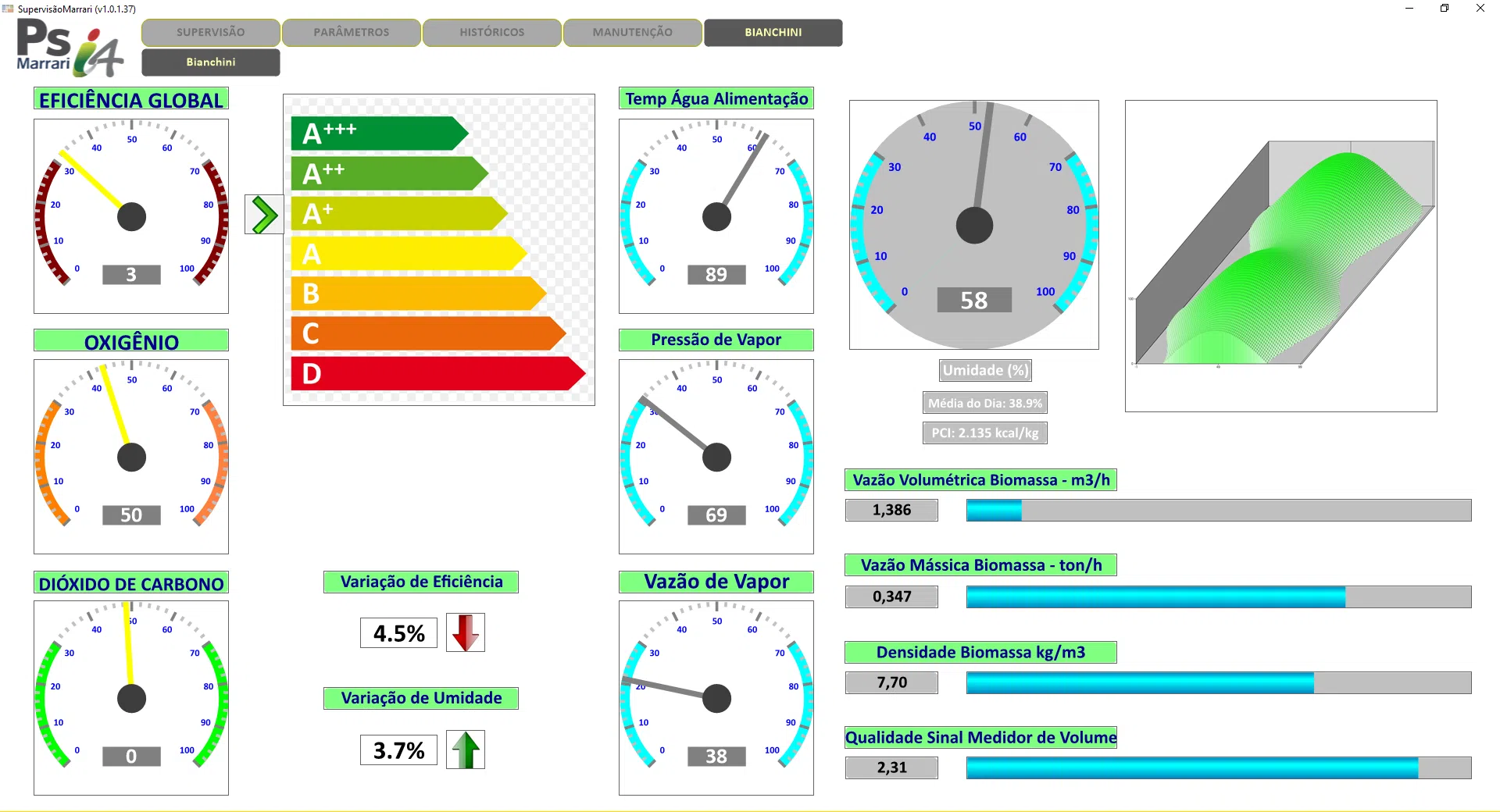

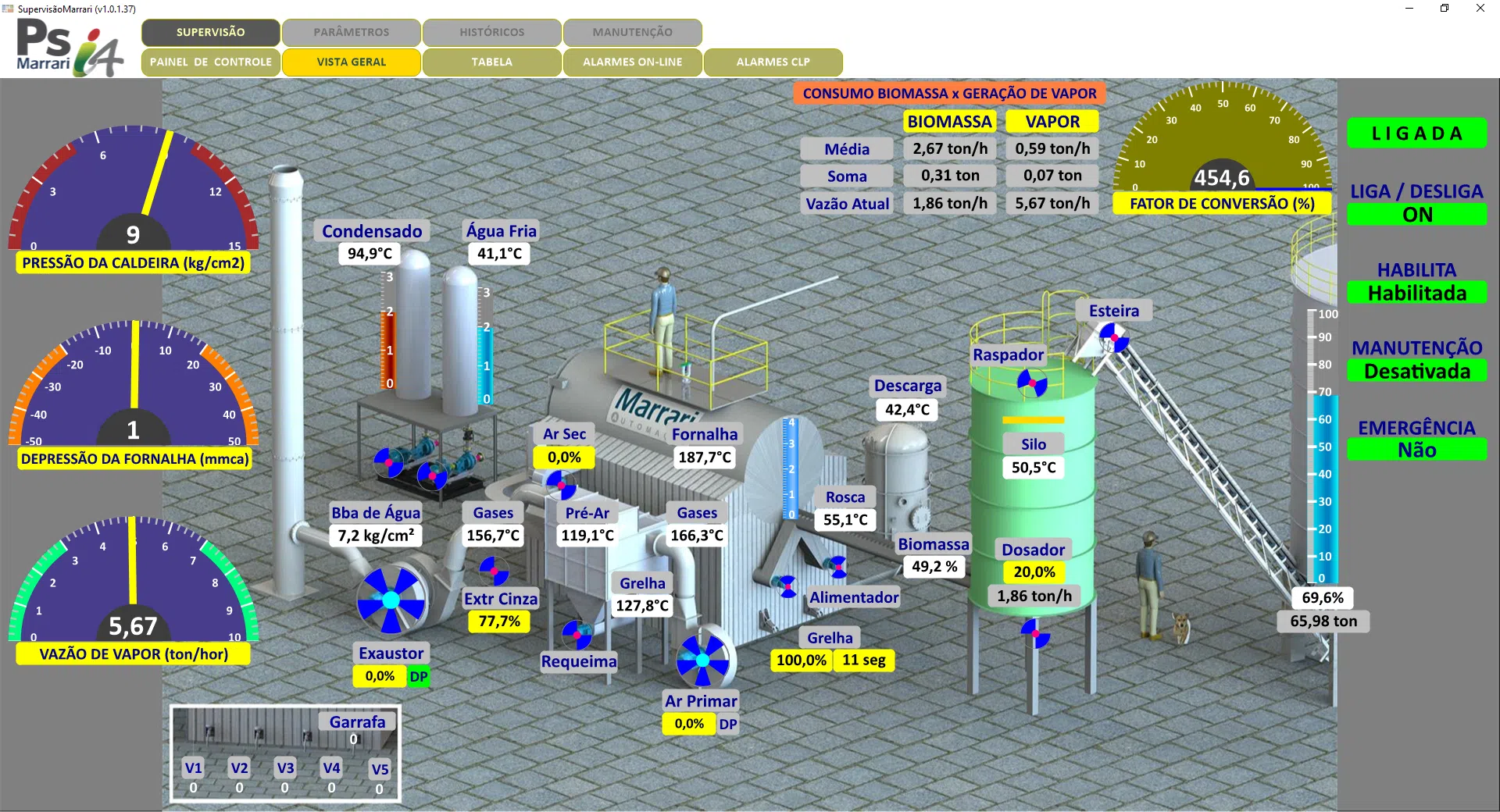

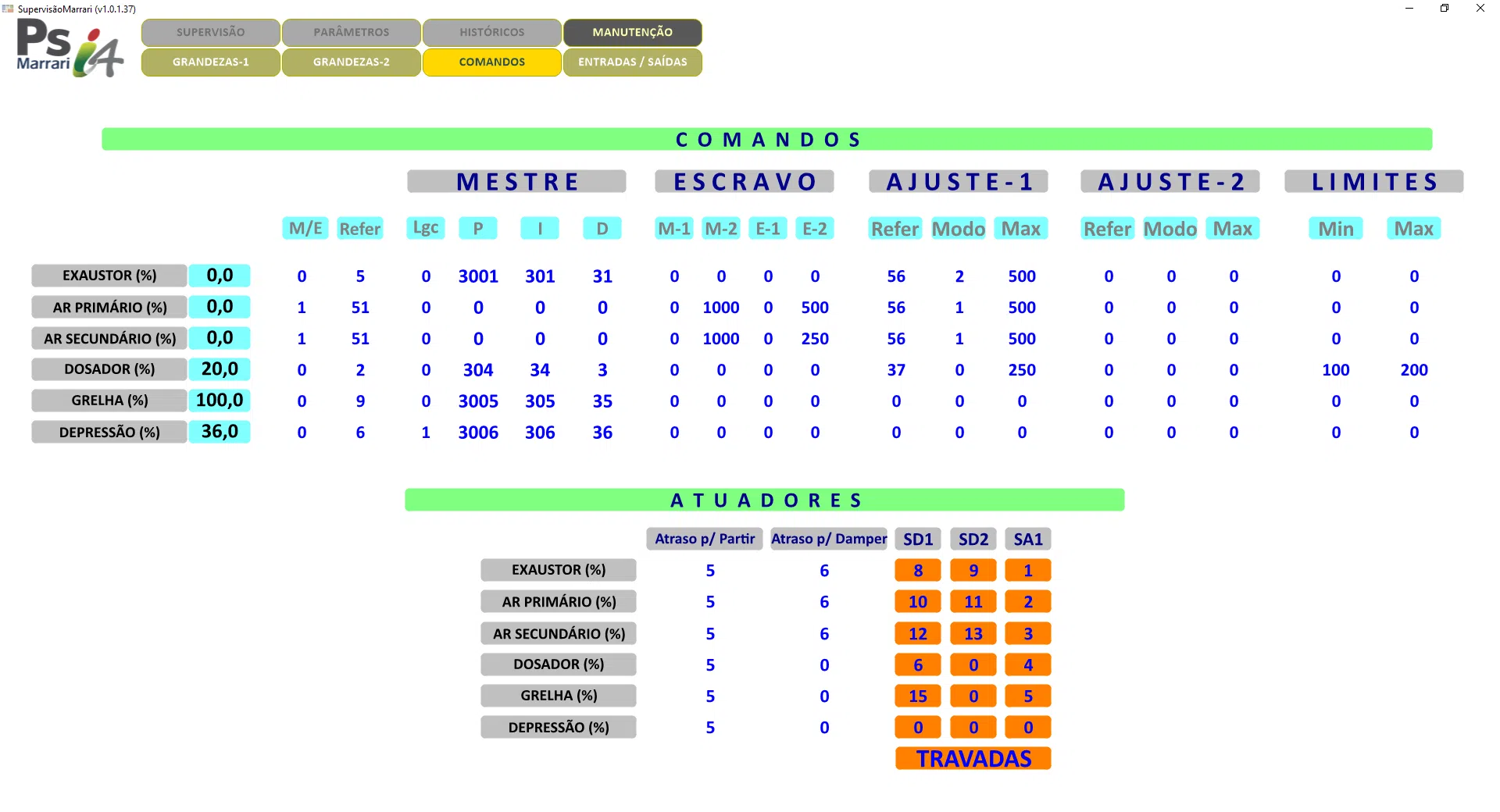

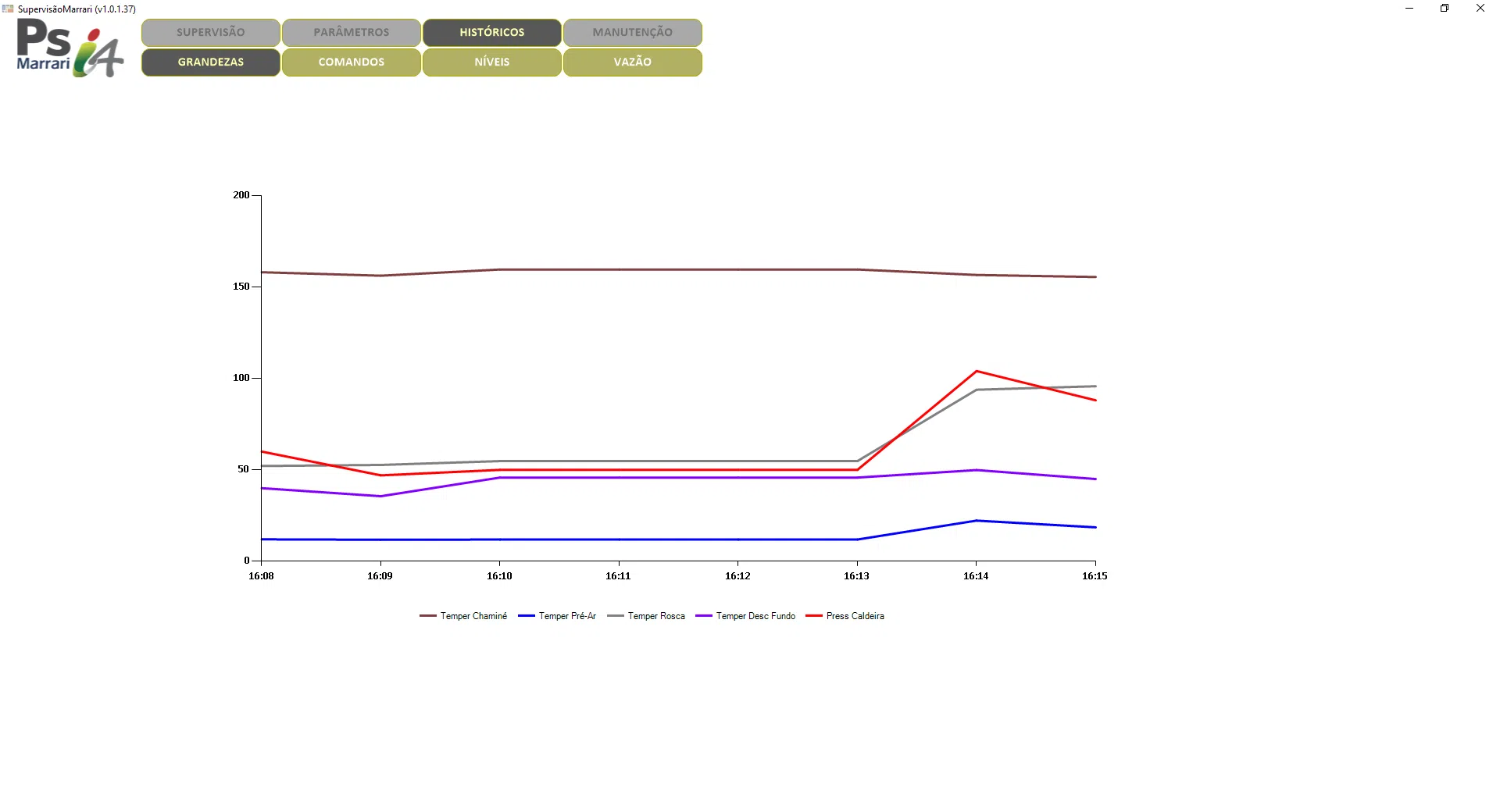

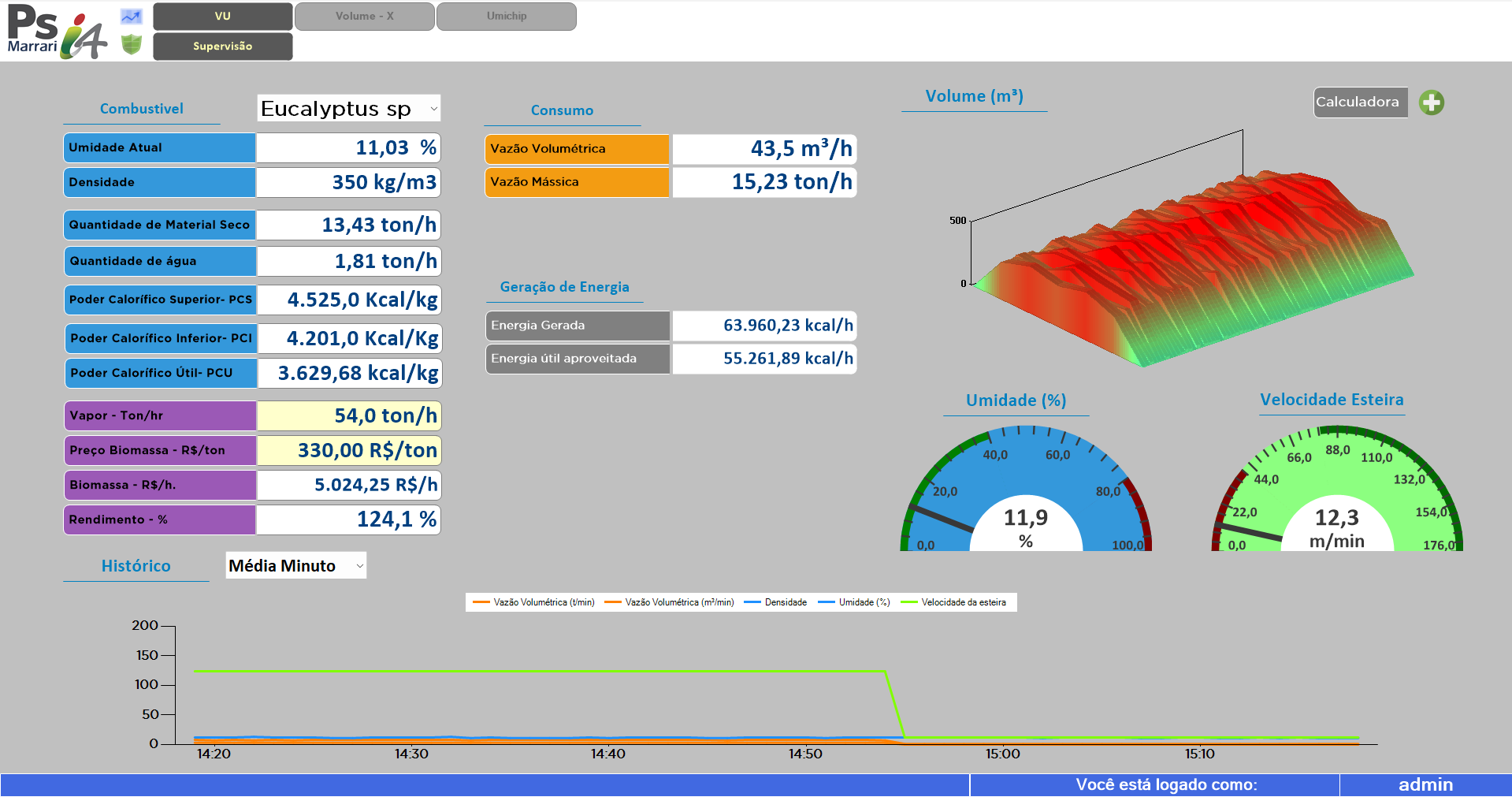

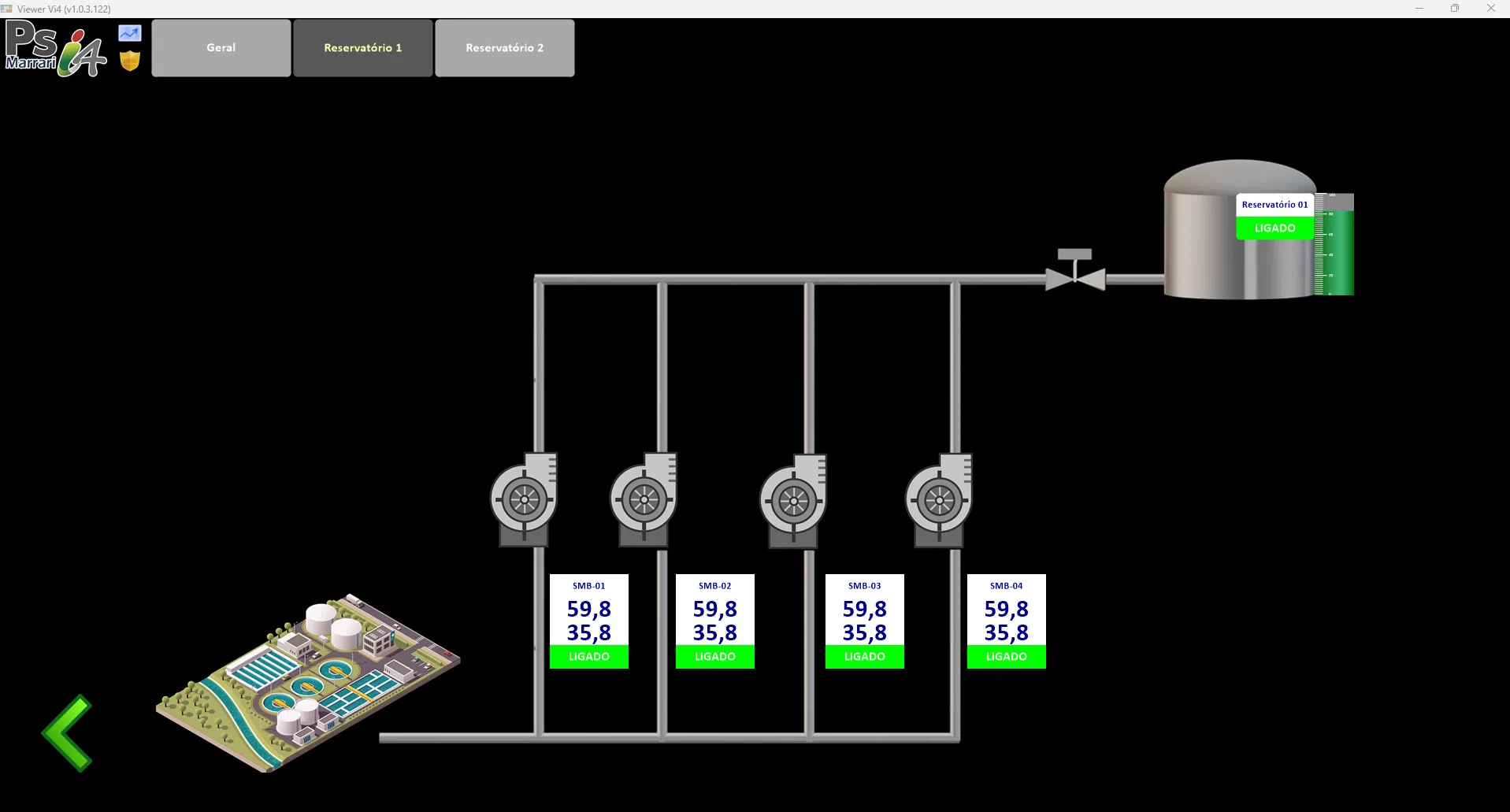

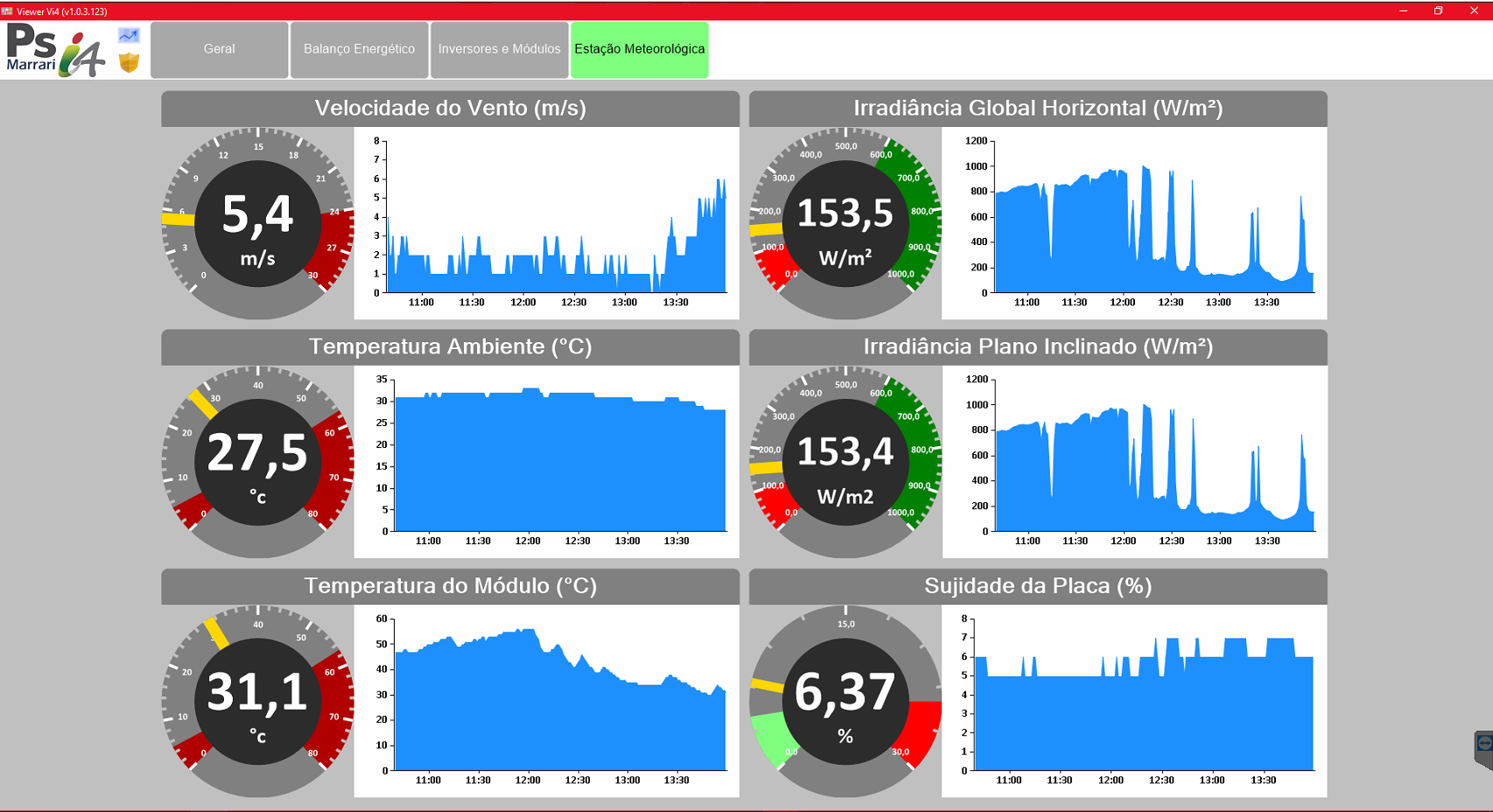

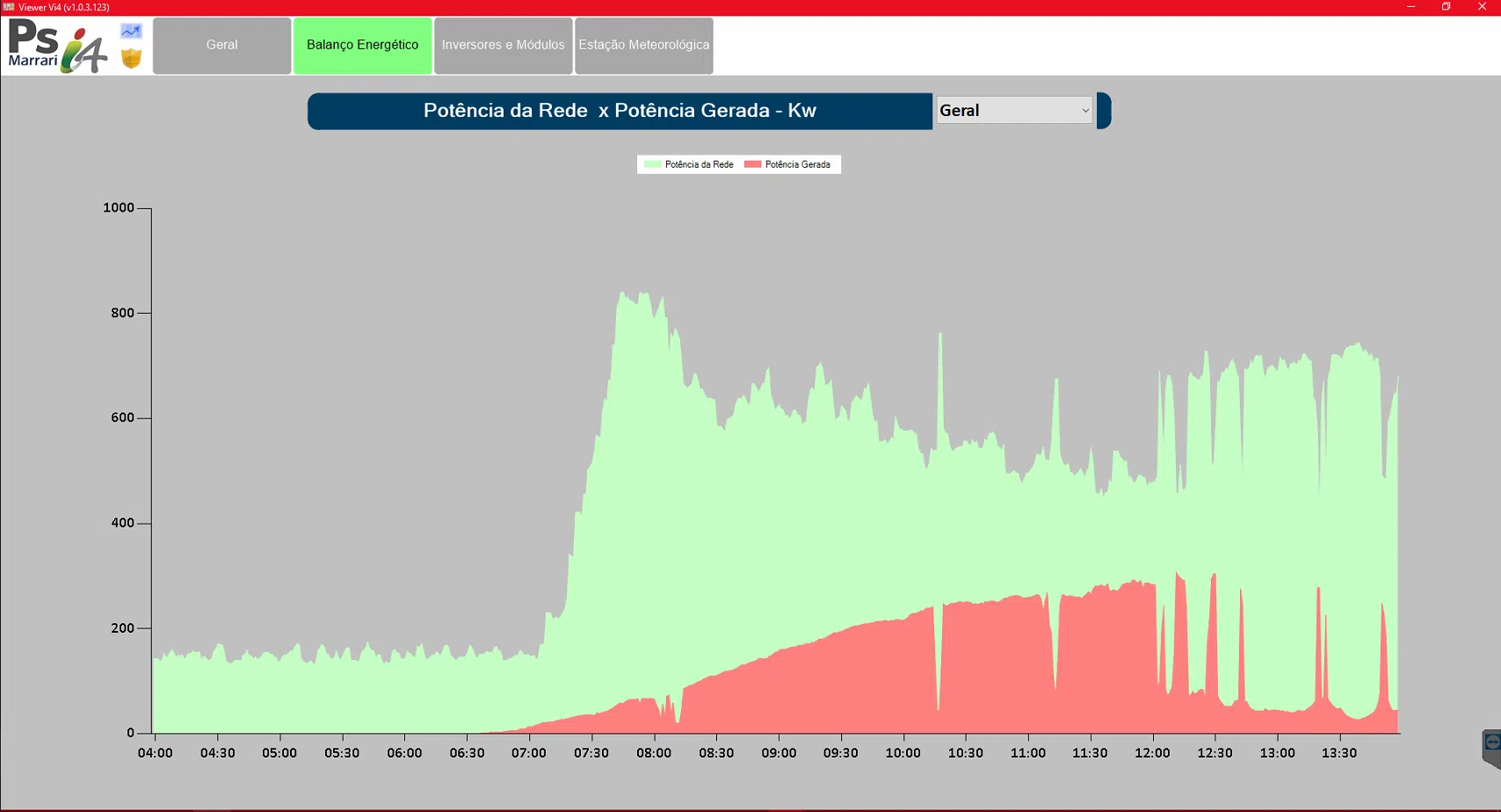

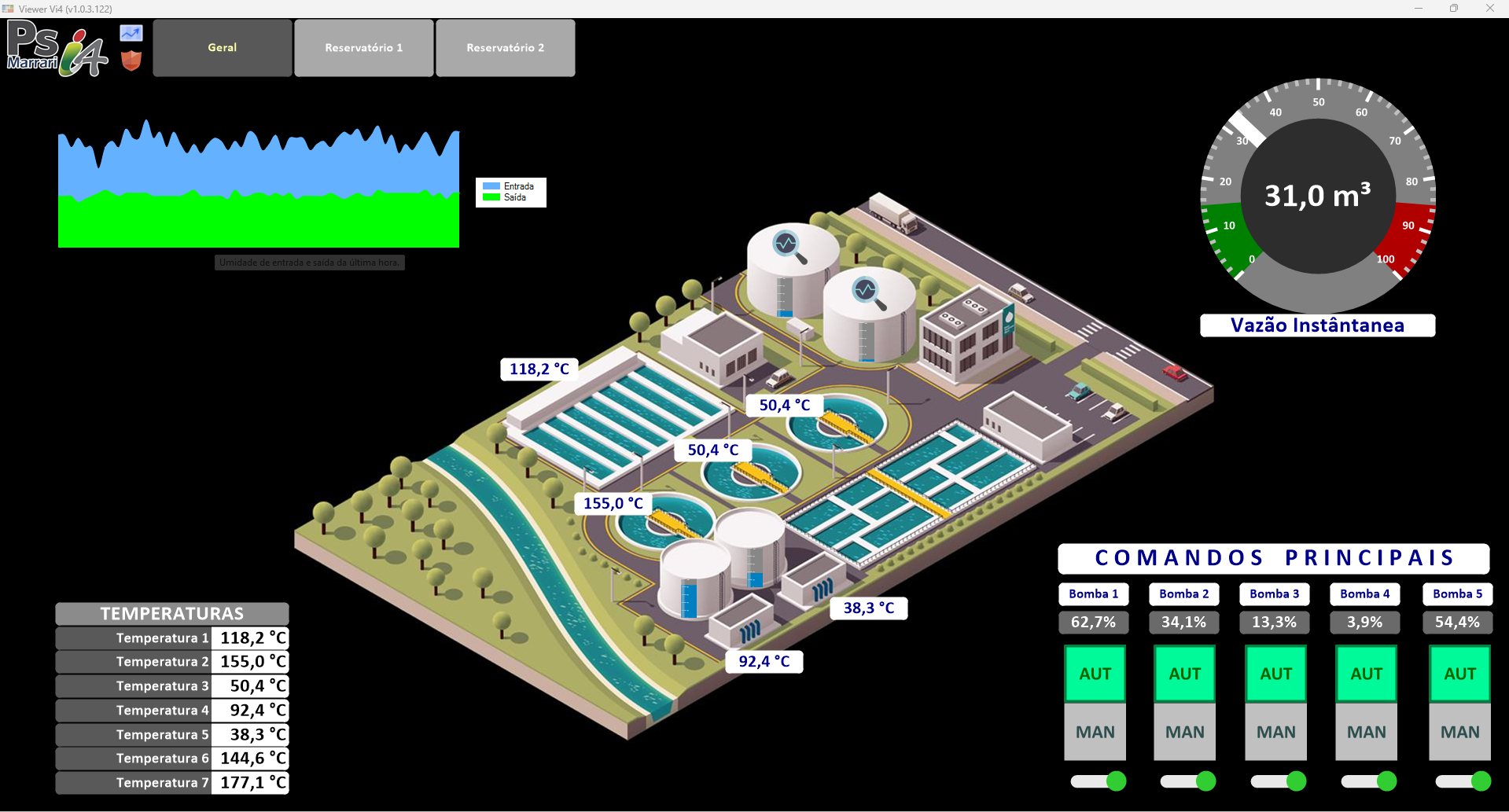

The Vi4 Viewer (within the SCADA industrial control platform) provides a unified environment with tools for developing and visualizing supervision screens, providing greater agility in editing and using supervision features. The interface is fully configurable, offering a library of images, text elements, multi-user access, alarms, graphs, and tables.

With the platform, it is possible to create and customize various supervision screens and dashboards for your process in a personalized manner without the need for a programmer, making it an easy-to-manage software.

Mi4 Additional Modules

The Mi4 Modules are general-purpose or custom software for each application. These modules perform a variety of tasks, such as sending alarms and events via email and mobile devices, integration with other databases, data generation for production control, advanced process control (machine learning), and various customizations.

What are the differentiating features of PSi4?

There are several differentiating features, starting with the non-obligation to rely on an external programmer or Marrari to create the supervisory systems, and more:

- Alarms, notifications, and alerts sent directly to your mobile phone via Telegram.

- An active support team to assist with any issues, both online and in-person.

- Exclusive discounts and training for those who want to become authorized system integrators for Marrari.

- User-friendly supervision UI that is easy to understand, modify, and customize to your needs.

- Utilization of the latest Microsoft coding, including AI and other cutting-edge technologies.

- No hidden or excessive costs, everything is shown at the time of purchase or subscription inclusion.

Can I buy it or just pay a subscription to use the supervisory system?

Marrari currently offers two modes of selling the PSi4 system: a full license purchase and a subscription-based payment for using the supervisory system. The main differences are:

With a license purchase:

No monthly fees are charged. You only pay extra if you want to add more tags or upgrade your version, such as going from version 1.0 to 2.0. All updates within your version are completely free, such as going from version 1.1 to 1.2 and so on.

With a subscription-based usage:

You receive all updates for your version and higher versions at no additional cost. You only pay for what you use, meaning you can adjust the number of tags according to your needs. Dedicated support team to assist with more complex configurations.

What are the main benefits of using an industrial control and supervisory SCADA system?

There are hundreds of benefits provided by a SCADA-style supervisory system, ranging from ease of data delivery to reports that aid in decision-making. Some of its main benefits include:

- Real-time process management.

- User-customized creation of specific processes for better management.

- Communication with numerous PLCs, remote components, and data hubs available in the market.

- Integration with ERP systems and other enterprise software.

- Quick integration and installation due to ease of use and our integrators.

- Rapid return on investment, focusing on the long term.

What are the modules of the PSi4 industrial SCADA supervisory system?

The modules are native components and can also be purchased to meet specific demands of each dashboard or application. Marrari can develop these modules for your company, or you can acquire them from our library of ready-made modules. To learn more about the modules of the supervisory system, please refer to the “PSi4 Features” below.