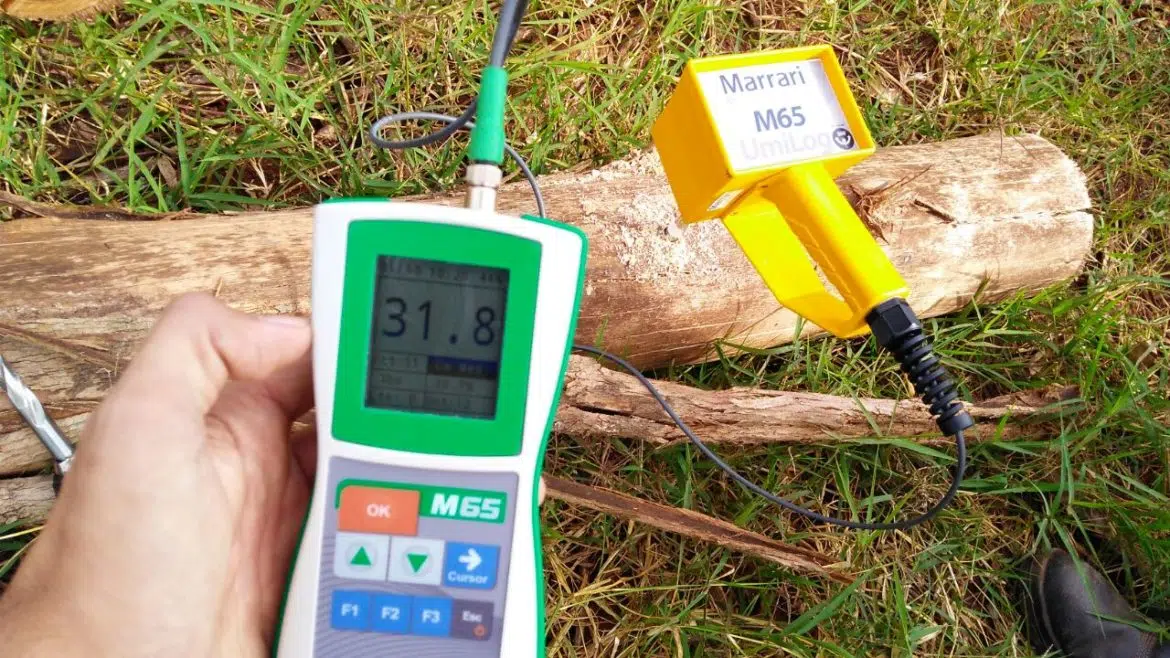

What is the Umilog M65 Log and Firewood moisture meter?

Also known as Umilog, the M65 log moisture meter is the right equipment for measuring moisture in logs and firewood. It stands out in its category for using the contact measurement method, making it more precise, effective, and reliable.

Why is this method important?

As a contact measurement method, when inserting the equipment’s probe into the interior of the log, approximately halfway through its diameter, it scans and calculates the total average moisture of the log, rather than just its surface.

This technology has proven to be extremely effective for both moist and dry logs.

For you, as a manager, leader, or production manager, what are the advantages of Umilog M65?

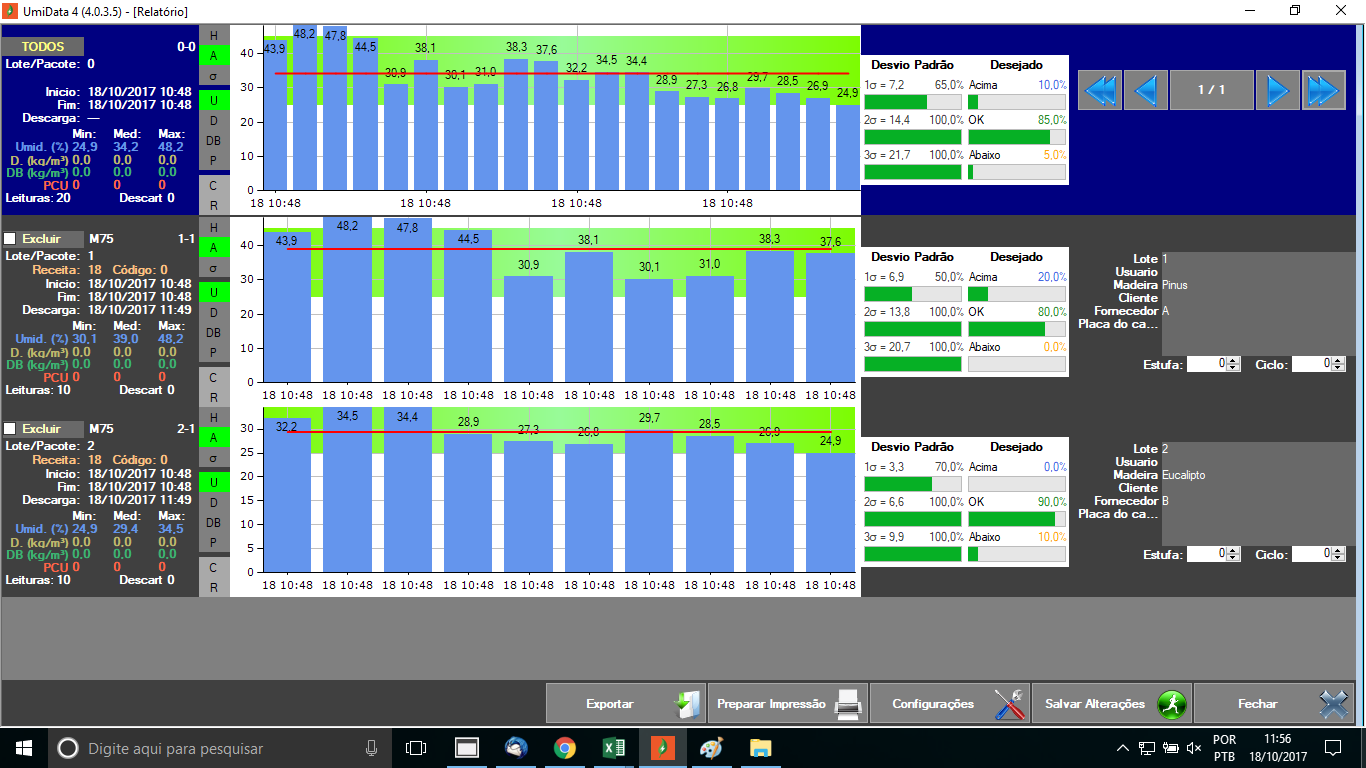

In addition to using this cutting-edge technology, it comes with our software, UmiData, a powerful tool for storing data collected by the meter and downloaded via USB to a PC.

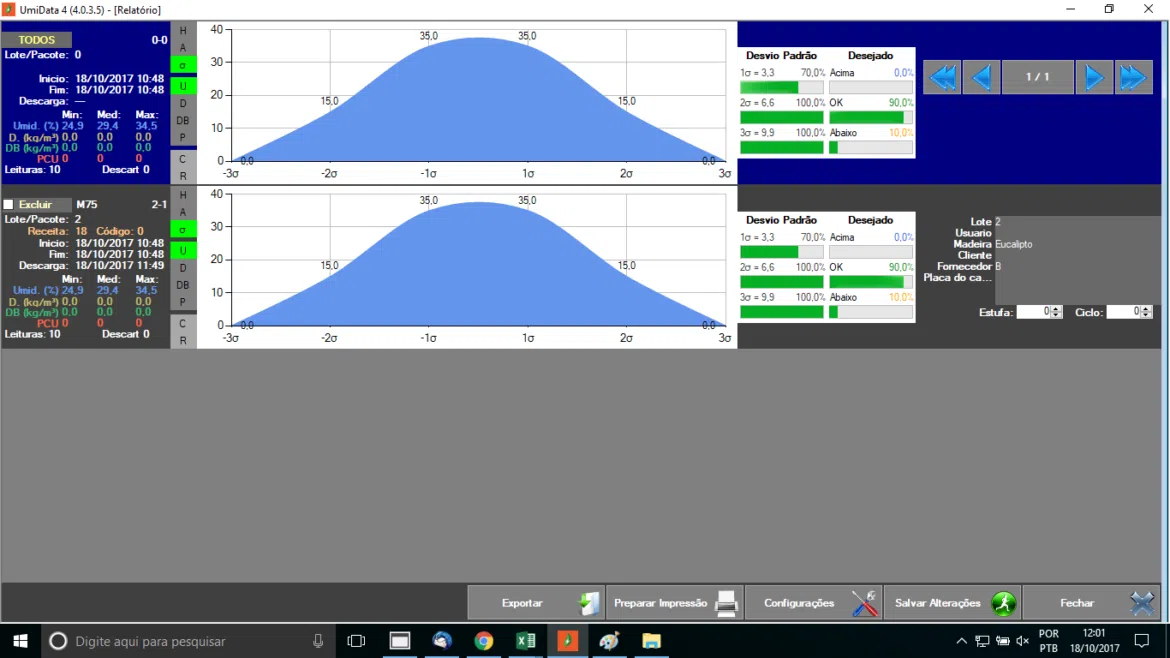

These data can then be displayed in various types of graphs, histories, and exported in Excel or other file formats.

What is the UmiData software?

UmiData is a powerful tool for data collection and storage. Through this supervisory tool, it’s possible to create and analyze recipes present in the equipment.

The collected data (moisture readings) can be downloaded via USB cable to a PC to be displayed through reports, graphs, histories, and tables. In addition to the online viewing of these reports, there is also the option to export them in CSV format to be read via Excel, ensuring better optimization for your company!

Benefits of knowing and having moisture data for logs and firewood:

1. Ensures Material Quality

Wood with high moisture content is more prone to decay, mold growth, and structural degradation. By measuring moisture, it’s possible to select high-quality wood, ensuring durability and optimal performance in final products.

2. Improved Combustion Efficiency

When used as fuel, wet wood reduces combustion performance. Moisture must evaporate before burning begins, which consumes extra energy and produces more smoke. Dry wood burns more efficiently and cleanly.

3. Energy and Resource Savings

Dry firewood delivers more heat per unit of weight or volume. This means less wood is needed to achieve the same thermal output, reducing energy consumption and operational costs.

4. Prevents Structural Damage in Construction

Using wet wood in buildings can cause warping, cracking, and dimensional changes over time. Measuring moisture ensures the material meets proper specifications and prevents structural issues.

5. Optimized Industrial Processing

In furniture and wood products manufacturing, moisture affects machining, gluing, and finishing. Monitoring moisture allows for process adjustments, ensuring higher product quality and consistency.

6. Proper and Safe Storage

Knowing the moisture content of logs and firewood helps define appropriate storage conditions. Excessively wet wood deteriorates faster, causing economic losses. Storing wood at the correct moisture level preserves its value.

7. Environmental Health

Burning dry wood reduces emissions of pollutants into the air, contributing to a cleaner environment and helping comply with environmental regulations.

8. Drying Process Planning

When high moisture levels are detected, appropriate drying processes — whether natural or in kilns — can be planned, ensuring the wood is suitable for use later on.

9. Quality Control and Standardization

Moisture measurement can be part of a broader quality control strategy, helping companies ensure their wood products meet required specifications and customer expectations.

10. Increased Fire Safety

Wet wood produces more creosote — a highly flammable residue — which can accumulate in chimneys and raise the risk of chimney fires. Controlling moisture levels improves safety in heating systems.

And why use Marrari equipment?

Our equipment is optimized for your company! We create ways to improve the performance of production processes without excessive loss using methods like OEE and Industry 4.0. This creates a more effective, productive, and modern production environment!

If you want to know more about us and automation news, visit our blog, Facebook, or LinkedIn.

GUARANTEE

Marrari offers a 6-month warranty for all its systems and equipment to ensure that your process is always as productive as possible!